Blood sensor and blood examining instrument including same

A blood test, sensor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

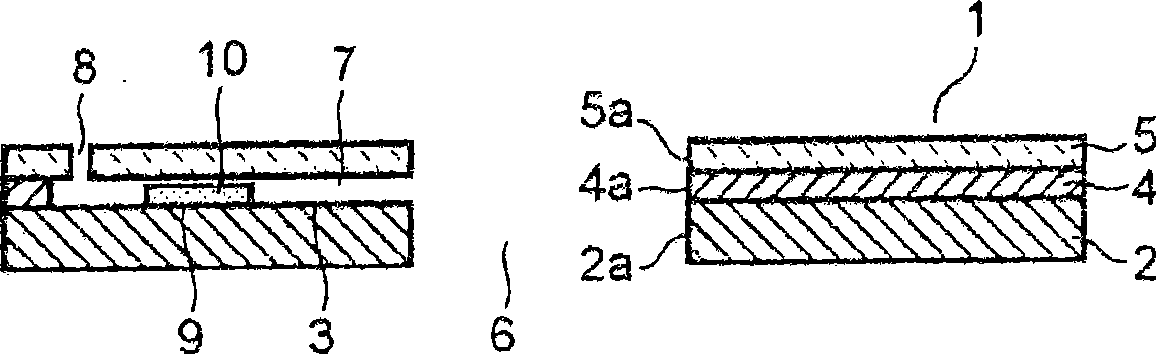

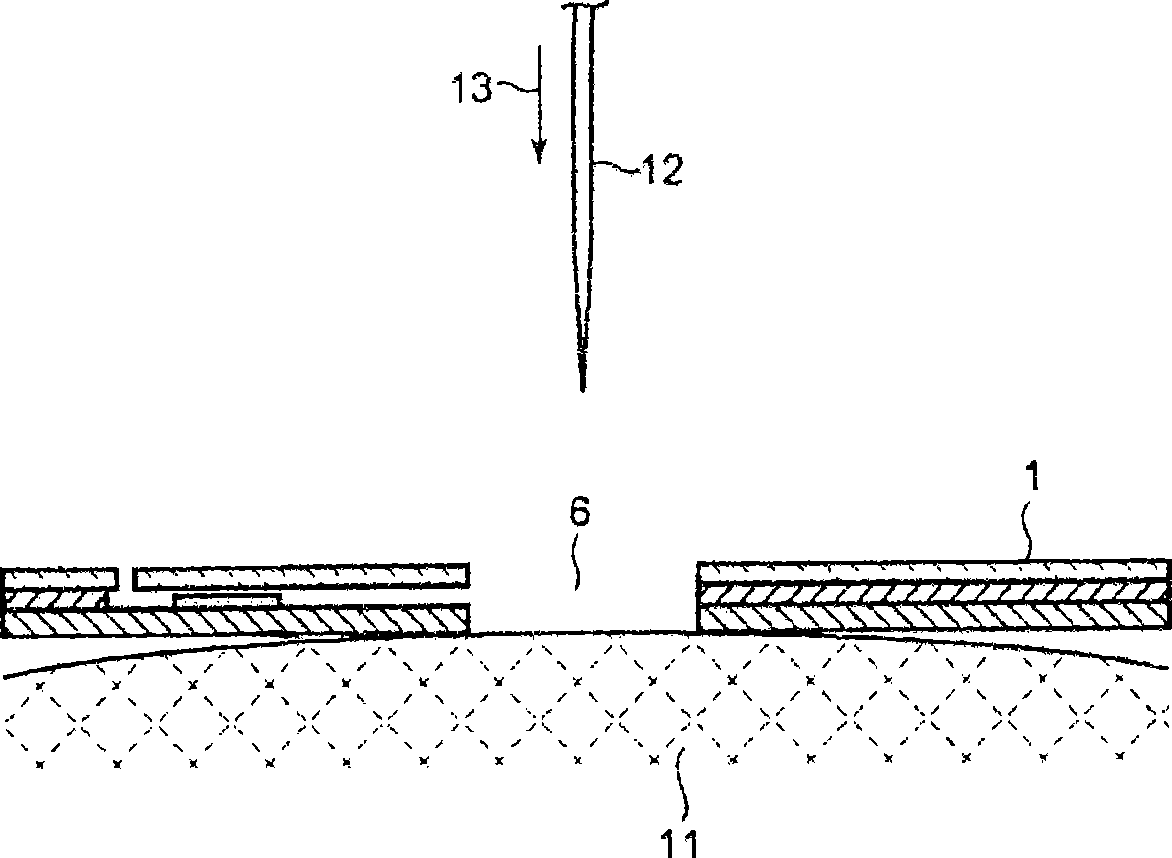

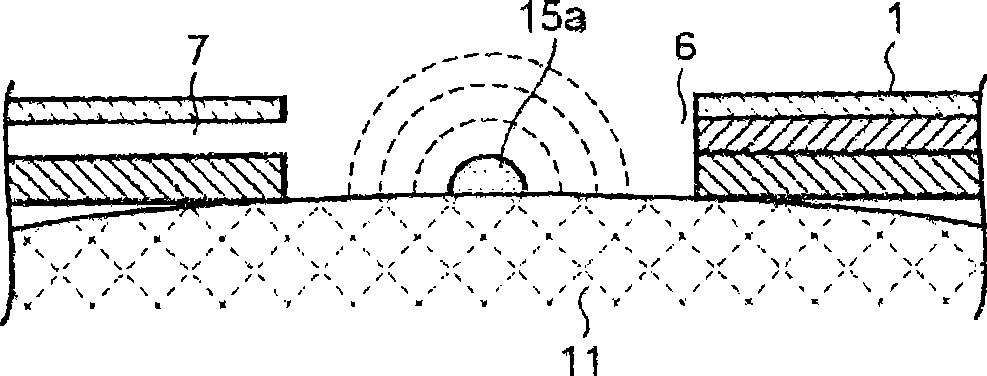

[0083] Figure 4 An example of the blood sensor of the present invention (Embodiment 1) is shown through FIG. 8 .

[0084] Figure 4 It is a sectional view of blood sensor 20a of Embodiment 1. Blood sensor 20 a has a plate shape and is composed of substrate 21 , spacer 22 attached to the upper surface of substrate 21 , and cover 23 attached to the upper surface of spacer 22 .

[0085] The blood storage part 24 is formed by communicating a substrate hole 21 a formed approximately in the center of the substrate 21 , a spacer hole 22 a formed approximately in the center of the spacer 22 , and a cover hole 23 a formed approximately in the center of the cover 23 . formed space. The blood storage part 24 is perforated downward or upward.

[0086] The lower surface of the substrate 21 of the blood sensor 20 a is brought into contact with the skin, and the skin in the blood storage part is punctured, whereby blood from the skin accumulates in the blood storage part 24 . One end o...

Embodiment approach 2

[0111] 9 and 10 show blood sensor 20b according to the second embodiment.

[0112] Blood sensor 20 b is different from blood sensor 20 a of Embodiment 1 in that groove 26 a is formed between substrate 21 and cover 23 . Hereinafter, this difference will be mainly described, and the same components as in Embodiment 1 will be given the same reference numerals and briefly described.

[0113] Figure 9A is a sectional view of the blood storage part 24 of the blood sensor 20b and its vicinity, Figure 9B is its perspective plan view. The diameter 21e of the substrate hole 21a formed in the substrate 21 is 1.6 mm. The diameter 22e of the spacer hole 22a formed in the spacer 22 is 2.0mm. Furthermore, the diameter 23e of the cover hole 23a formed in the cover 23 is 1.0 mm. The respective centers of the substrate hole 21a, the spacer hole 22a, and the cover hole 23a are on the same axis.

[0114] The blood storage part 24 of the blood sensor 20b is the same as the first embodiment...

Embodiment approach 3

[0120] 11 and 12 show blood sensor 20c according to the third embodiment.

[0121] Groove 26b similar to groove 26a of blood sensor 20b in Embodiment 2 is formed between substrate 21 and cover 23 of blood sensor 20c. However, unlike the groove 26a, the groove 26b is formed on the side of the supply path 25, and no groove is formed on the opposite side 24e of the supply path 25. Hereinafter, this difference will be mainly described, and the same components as those in the blood sensor 20b of Embodiment 2 will be given the same reference numerals and briefly described.

[0122] Figure 11A is a sectional view of the blood storage part 24 of the blood sensor 20c and its vicinity, Figure 11B is its perspective plan view. The diameter 21f of the substrate hole 21a formed in the substrate 21 is 1.8 mm. The diameter 22f of the spacer hole 22a formed in the spacer 22 is 2.0 mm. Furthermore, the diameter 23f of the cover hole 23a formed in the cover 23 is 1.0 mm.

[0123] The ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com