Electronic part device and method of manufacturing it and electronic part assembly and method of manufacturing it

A technology of electronic components and components, which is applied in the fields of electronic component devices and their manufacturing and electronic component components and their manufacturing, can solve problems such as weak cut-off force, achieve the effect of preventing melting erosion and maintaining reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

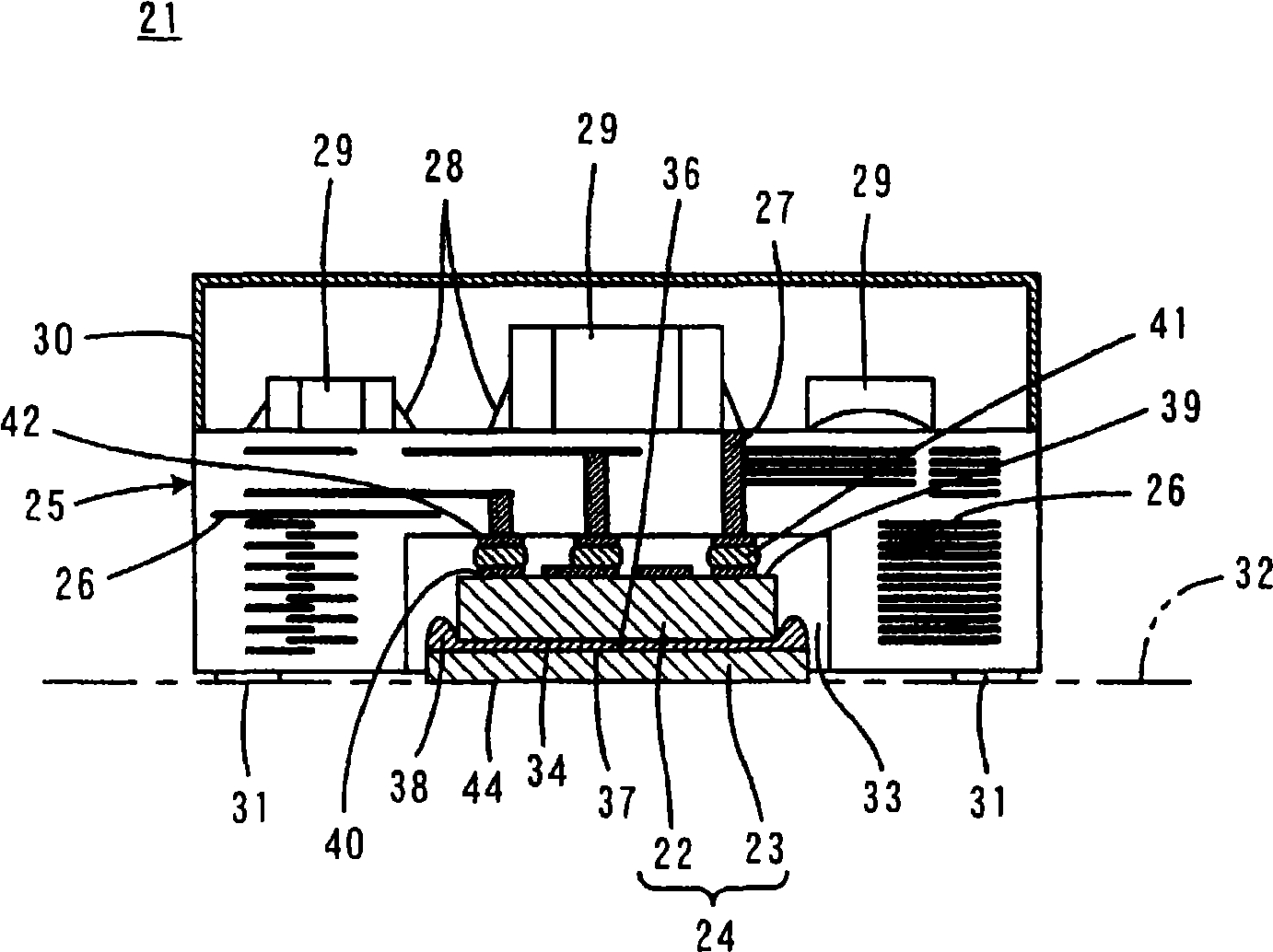

[0057] figure 1 It is a sectional view showing the electronic component module 21 according to one embodiment of the present invention.

[0058] The electronic component module 21 includes an electronic component device 24 having a structure in which a metal plate 23 and an electronic component element 22 are joined. Furthermore, the electronic component module 21 has a case 25 in which the above-mentioned electronic component device 24 is accommodated.

[0059] The case 25 has a multilayer structure in which a plurality of ceramic layers or organic material layers are laminated, and several internal conductor films 26 and several via conductors 27 are formed inside. Passive components such as inductors, capacitors, and resistors are formed by wiring conductors including these inner conductor films 26 and via-hole conductors 27 .

[0060] On the upper surface of the case 25, if necessary, several external conductor films (not shown.) are formed, and in a state connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com