Eraser

An eraser and liquid technology, applied in the field of erasers, can solve the problems of simultaneous realization of migration resistance and rubber crumb accumulation, and achieve excellent rubber crumb accumulation, high environmental pollution resistance, and excellent migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

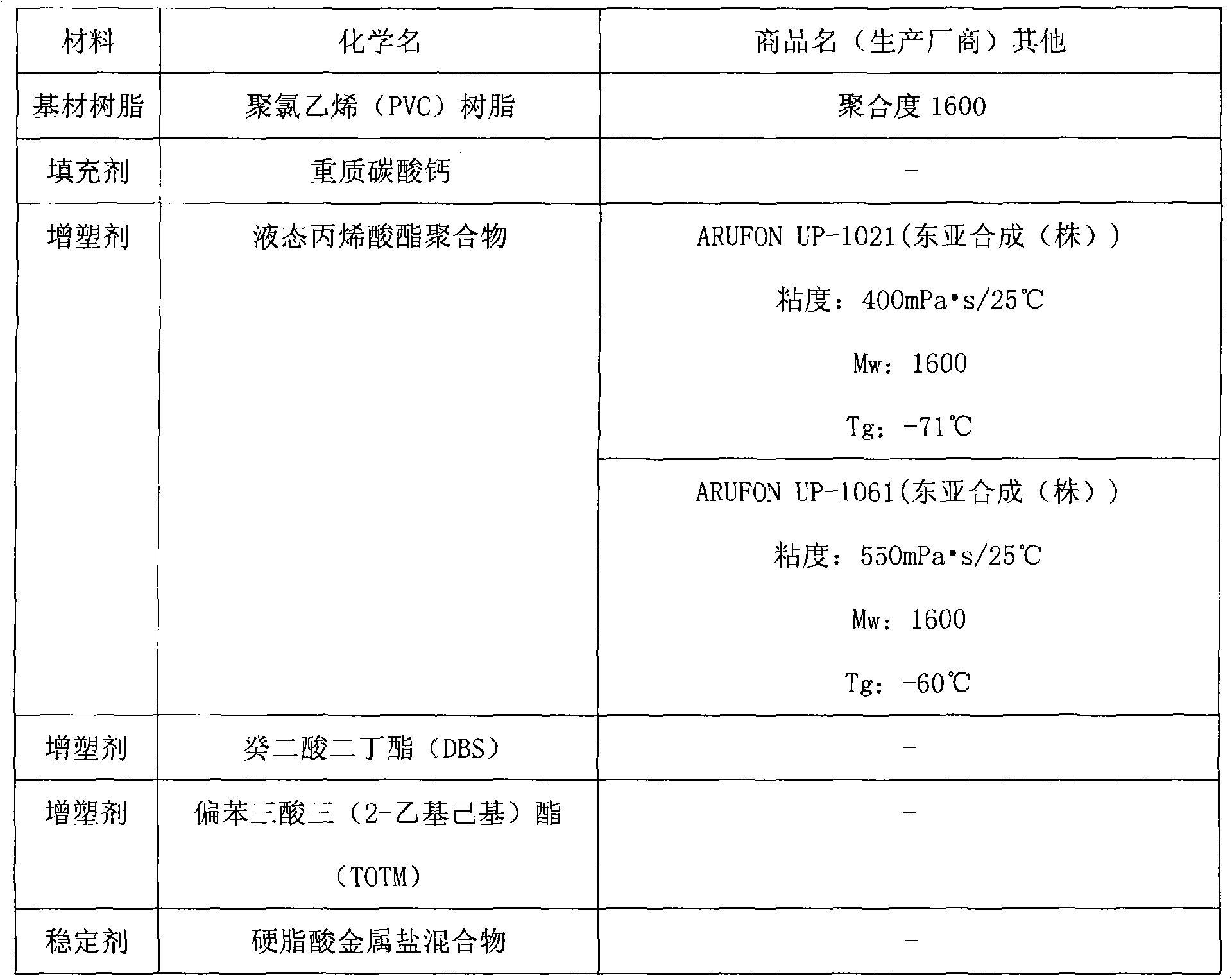

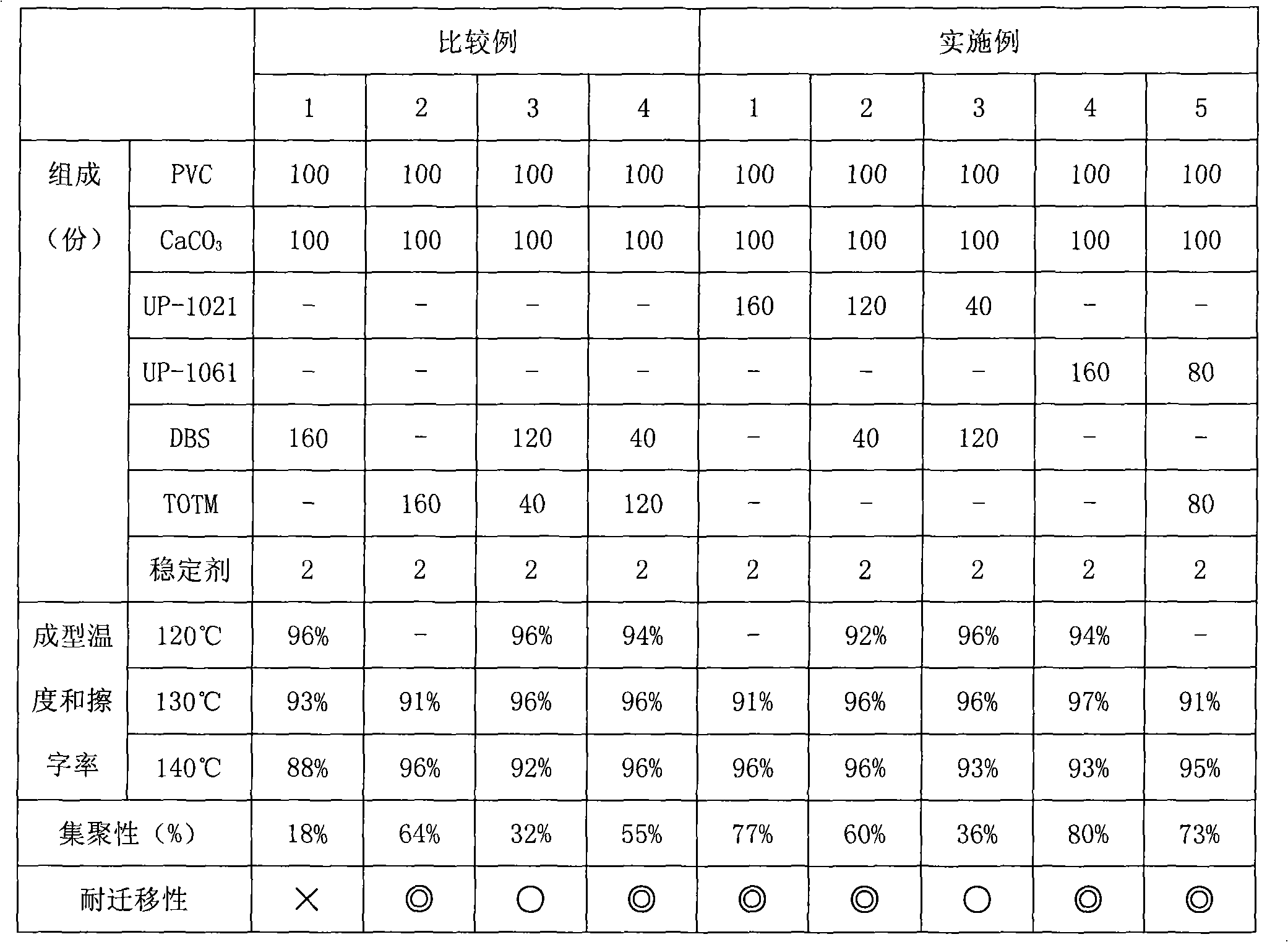

[0046] (Examples 1-5, Comparative Examples 1-4)

[0047] After mixing and stirring the compounded resin composition shown in Table 2 and vacuum defoaming, it was poured into a 100×100×10mm mold kept at 120-140°C, heated for 30 minutes, cooled, and taken out from the mold to obtain a test sample. Sample. The erasing rate, rubber crumb accumulation and mobility of each sample were measured according to the above method, and the results are shown in Table 2.

[0048] Table 2

[0049]

[0050] As can be clearly seen from Table 2, by blending a liquid acrylic polymer as a plasticizer, an eraser excellent in migration resistance and accumulation of rubber crumbs can be obtained. In addition, it was found that when a liquid acrylic polymer and other plasticizers are used in combination, both the migration resistance and the accumulation of rubber crumbs are improved compared to the conventional eraser containing only ester plasticizers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com