Element for generating a magnetic field

A technology for components and magnetic fields, applied in the field of components that generate magnetic fields, can solve problems such as taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

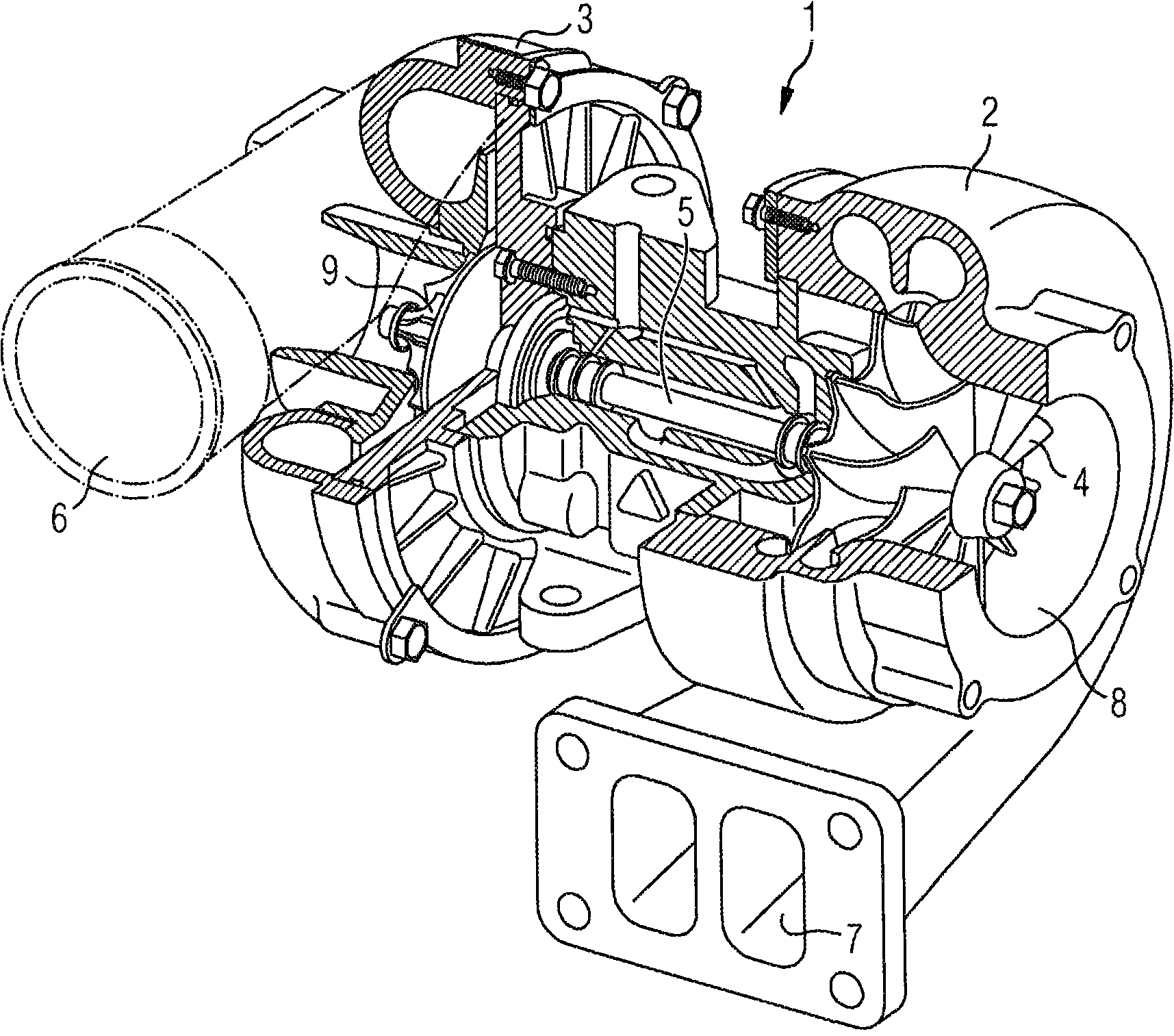

[0020] figure 1 An exhaust gas turbocharger 1 with a turbine 2 and a compressor 3 is shown. The compressor wheel 9 is rotatably mounted in the compressor 3 and connected to the turbine shaft 5 . The turbine shaft 5 is also mounted rotatably and is connected at its other end to the turbine wheel 4 . The combination of the compressor wheel 9 , the turbine shaft 5 and the turbine wheel 4 is also referred to as a rotor assembly. Hot exhaust gases from an internal combustion engine (not shown here) are discharged into the turbine 2 via the turbine inlet 7 , wherein the turbine wheel 4 is in rotation. The exhaust gas flow leaves the turbine 2 through the turbine outlet 8 . The turbine wheel 4 is connected to a compressor wheel 9 via a turbine shaft 5 . The turbine 2 thus drives the compressor 3 . In the compressor 3 , air is sucked in via the air inlet 16 , subsequently compressed in the compressor 3 and delivered to the internal combustion engine via the air outlet 6 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com