Energy storage module

A technology for energy storage modules and storage components, which is used in the manufacture of final products, electrolytic capacitors, multiple hybrid/electric double layer capacitors, etc., and can solve the problem that the system cannot be placed in the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

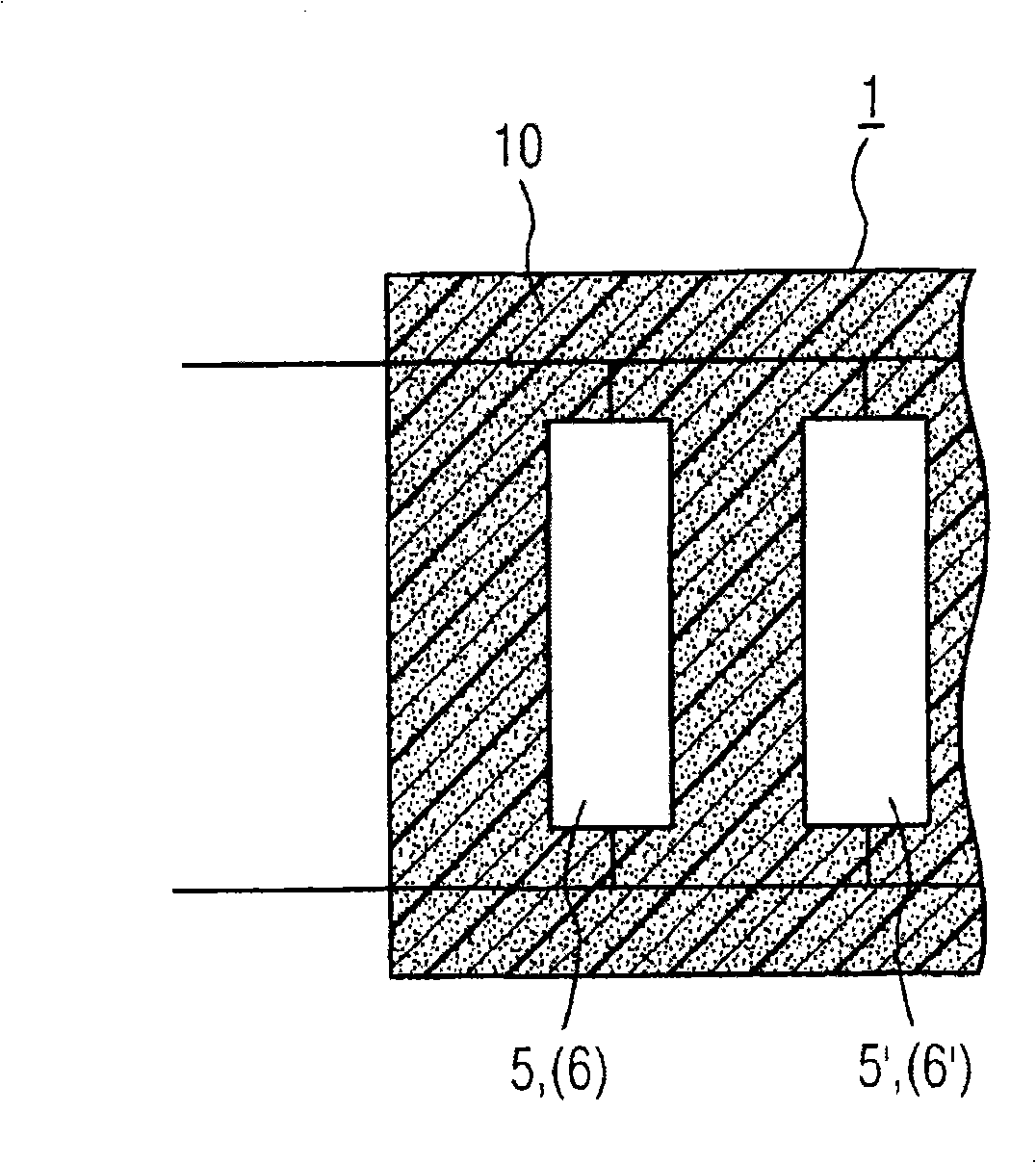

[0017] exist figure 1 An energy storage module is shown in , which is mainly composed of an outer casing 1 that is hermetically closed. In the module housing 1 a plurality of capacitors are connected in succession as individual electrolyzers, which capacitors are implemented as energy stores for certain applications in industrial plants, in particular also in passenger vehicles. In particular double layer capacitors 5 are considered as capacitors. As an alternative to this, known electrolytic capacitors 6 can also be used. exist figure 1 Special double layer capacitors 5, 5', 5", . . . are shown in .

[0018] The double-layer capacitor 5 or electrolytic capacitor 6 used uses a combustible organic electrolyte, respectively. In the event of a fault, combustion, explosion or at least deflagration can take place here. Appropriate security measures must be taken for this purpose. This measure should satisfy the principle of intrinsic safety, ie no other functional elements sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap