Light-cured composite resin for oral cavity by using single crystal diamond as filler and preparation method thereof

A single crystal diamond, composite resin technology, applied in dental preparations, digestive systems, drug combinations, etc., can solve the problems of not improving wear resistance and flexural strength, high price of artificial nano-diamonds, no obvious changes, etc. The method is simple and easy to implement, the performance is improved, and the flexural strength and microhardness are improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

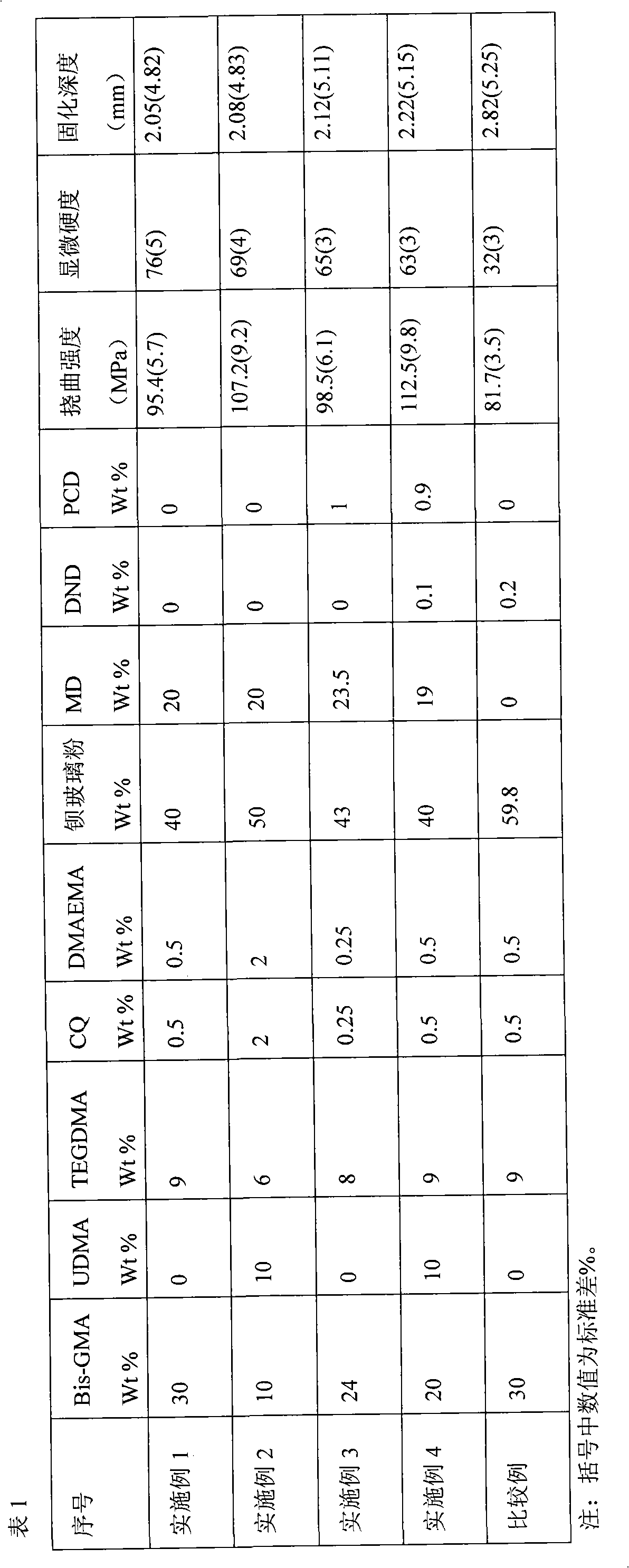

Examples

Embodiment

[0025] 1. Preparation method of composite resin:

[0026] (1) Equipped with resin monomer: mix dimethacrylate-based main monomer and diluent according to the amount, dissolve it in acetone, add it into the self-made experimental device and stir evenly,

[0027] (2) Add initiator (photoinitiator and co-initiator) according to the amount, and continue to stir under the dark;

[0028] (3) Modification (coupling) base material respectively: join a certain amount of base material in ethanol, ultrasonically disperse for 30 minutes, then add the silane coupling agent after hydrolysis with base material weight ratio 1: 1, at 50 Stir and react at ℃ for about 24 hours, then centrifugally dry to obtain the modified base material.

[0029] (4) Add the modified barium glass powder into the solution of (2) according to the amount, and continue to stir at a speed of 3000r / min for 15min while ultrasonicating.

[0030] (5) Vacuum the experimental device with a vacuum pump to remove the solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com