Testing device for detecting and controlling lubricating oil circulation rate of refrigerating system

A technology for lubricating oil and circulation rate, which is applied in the field of testing devices for detecting and controlling the circulation rate of lubricating oil in refrigeration systems, and can solve the problem of inability to test and analyze the quantitative influence of lubricating oil circulation volume, large fluctuations, and inability to measure lubricating oil circulation volume, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

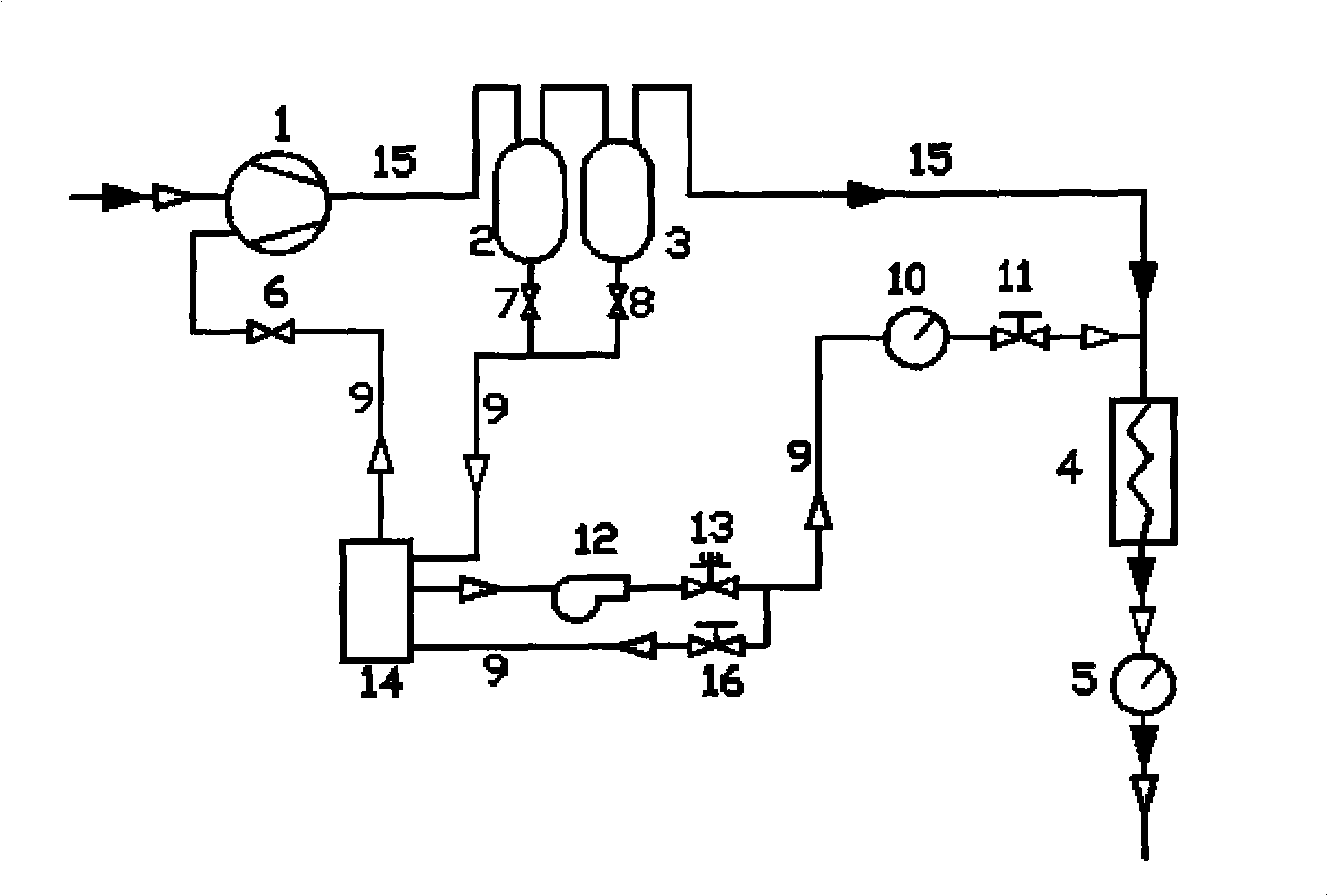

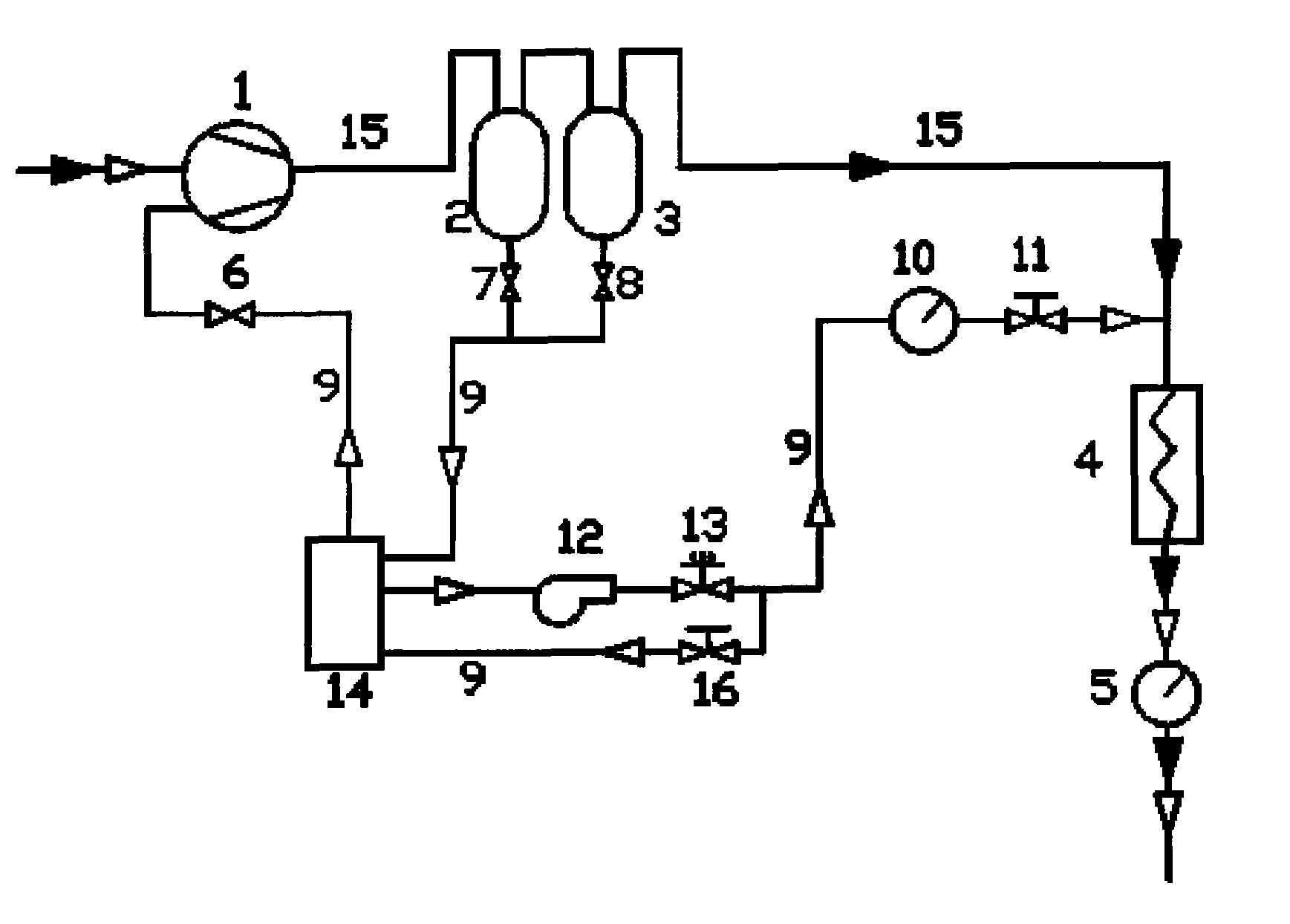

[0015] Such as figure 1 As shown, this embodiment includes a compressor 1, a primary oil separator 2, a secondary oil separator 3, a condenser 4, a first flow meter 5, a shut-off valve 6, maintenance valves 7 and 8, and a lubricating oil pipeline 9 , the second flow meter 10 , the first manual needle valve 11 , the oil pump 12 , the solenoid valve 13 , the oil storage tank 14 , the refrigerant pipeline 15 , and the second manual needle valve 16 . Wherein: the compressor 1, the primary oil separator 2, the secondary oil separator 3, the condenser 4, and the refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com