Automatic checking method for smoke box discharged from formulation library

A recipe library and smoke box technology, which is applied in the fields of tobacco, tobacco preparation, conveyor control devices, etc., can solve the problems of large staffing, low efficiency, and high labor intensity, and achieve the goals of reducing staffing, accurate formulas, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

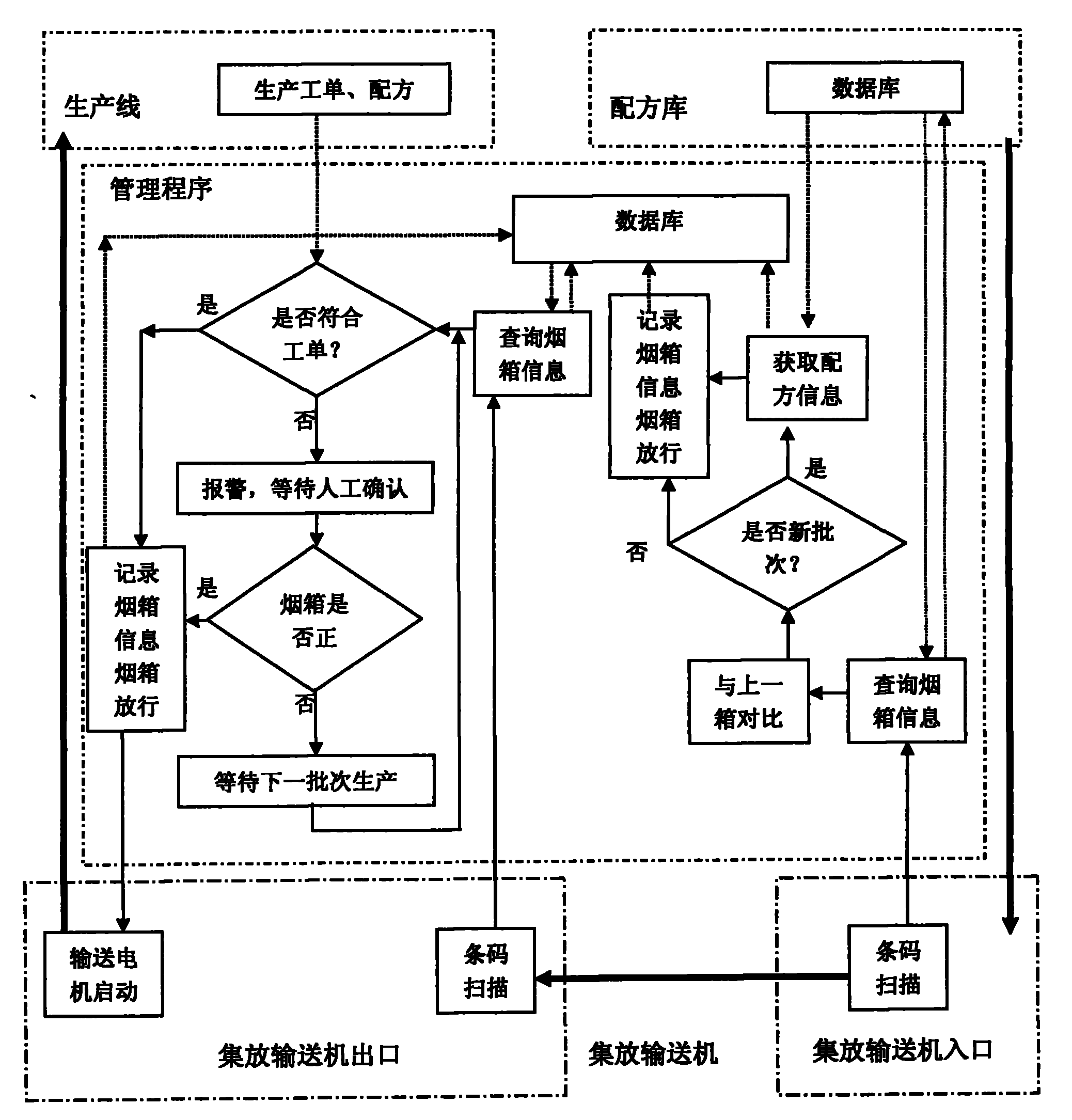

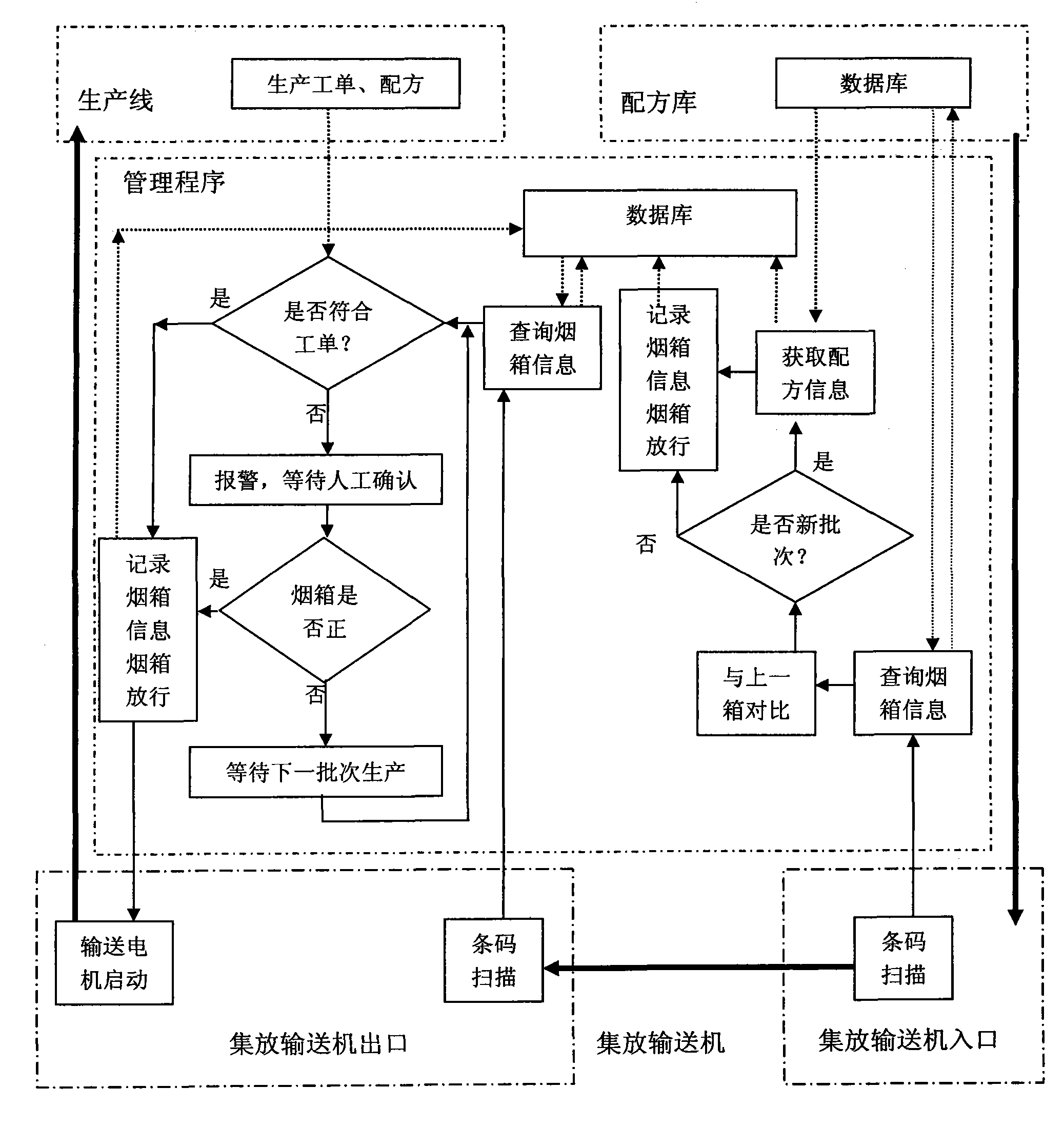

[0011] Accompanying drawing has provided the flow chart of the present invention, and the method of the present invention is described in detail below in conjunction with accompanying drawing, in this flow chart, the thick solid line represents the smoke box operation route, the thin solid line represents the program control flow, and the dotted line represents the direction of information.

[0012] After the smoke boxes leave the warehouse from the formula warehouse, they enter the collection conveyor through the entrance of the collection conveyor, are transported to the exit through the collection conveyor, and then enter the production line from the exit of the collection conveyor. The management program is mainly for the collection conveyor Take control.

[0013] First, scan the barcode of the cigarette box at the entrance of the collecting and releasing conveyor, query the formula library database according to the barcode, and obtain information such as the material numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com