A fully automatic steel loading method for slab number detection based on machine vision

A technology of machine vision and slab number, applied in instruments, computer parts, calculations, etc., can solve the problems of low production efficiency, high labor intensity, mixed steel, etc., and achieve the effect of improving production efficiency and speeding up the rhythm of steel loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

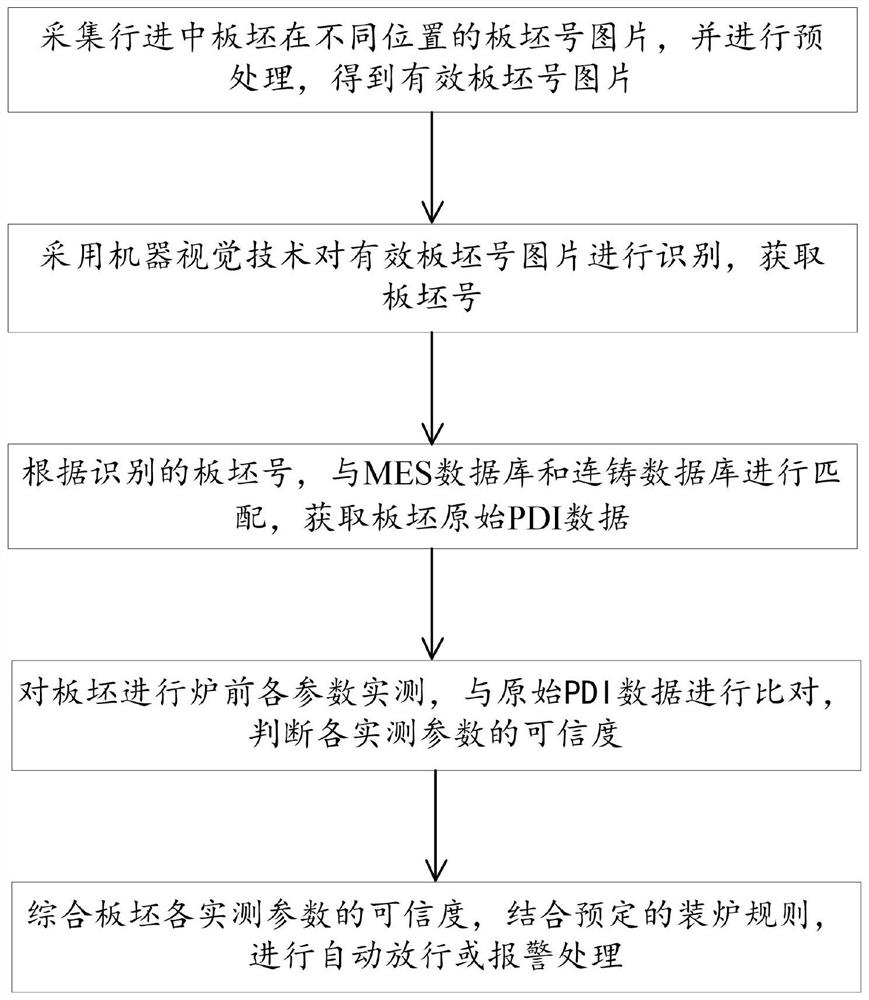

[0050] Embodiments of the present invention provide a machine vision-based slab number detection fully automatic steel loading method, such as figure 1 As shown, the method includes the following steps:

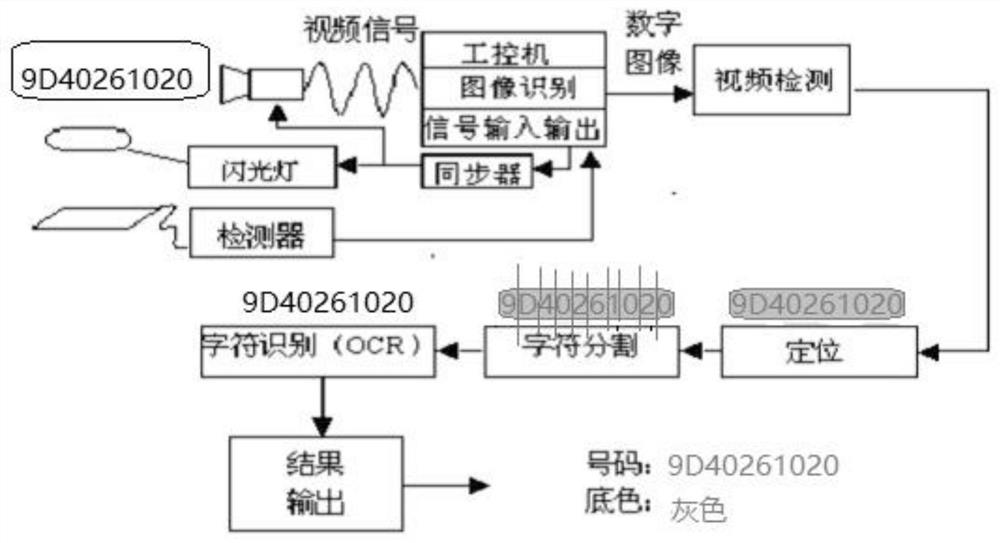

[0051] Collect pictures of slab numbers in different positions of the moving slabs, and perform preprocessing to obtain valid slab number pictures;

[0052] Use machine vision technology to identify valid slab number pictures to obtain the slab number;

[0053] According to the identified slab number, match with the MES database and the continuous casting database to obtain the original PDI data of the slab;

[0054] Measure the parameters of the slab before the furnace, compare with the original PDI data, and judge the reliability of the measured par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com