Heat-peelable pressure-sensitive adhesive sheet and method of recovering adherend

A technology of thermal peeling and adhesive sheet, which is applied in the direction of adhesive heating bonding method, polymer adhesive additive, film/sheet adhesive, etc., and can solve the problem of contact between the adhesive layer and the adherend Problems such as insufficient area reduction, inability to peel, and time-consuming peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

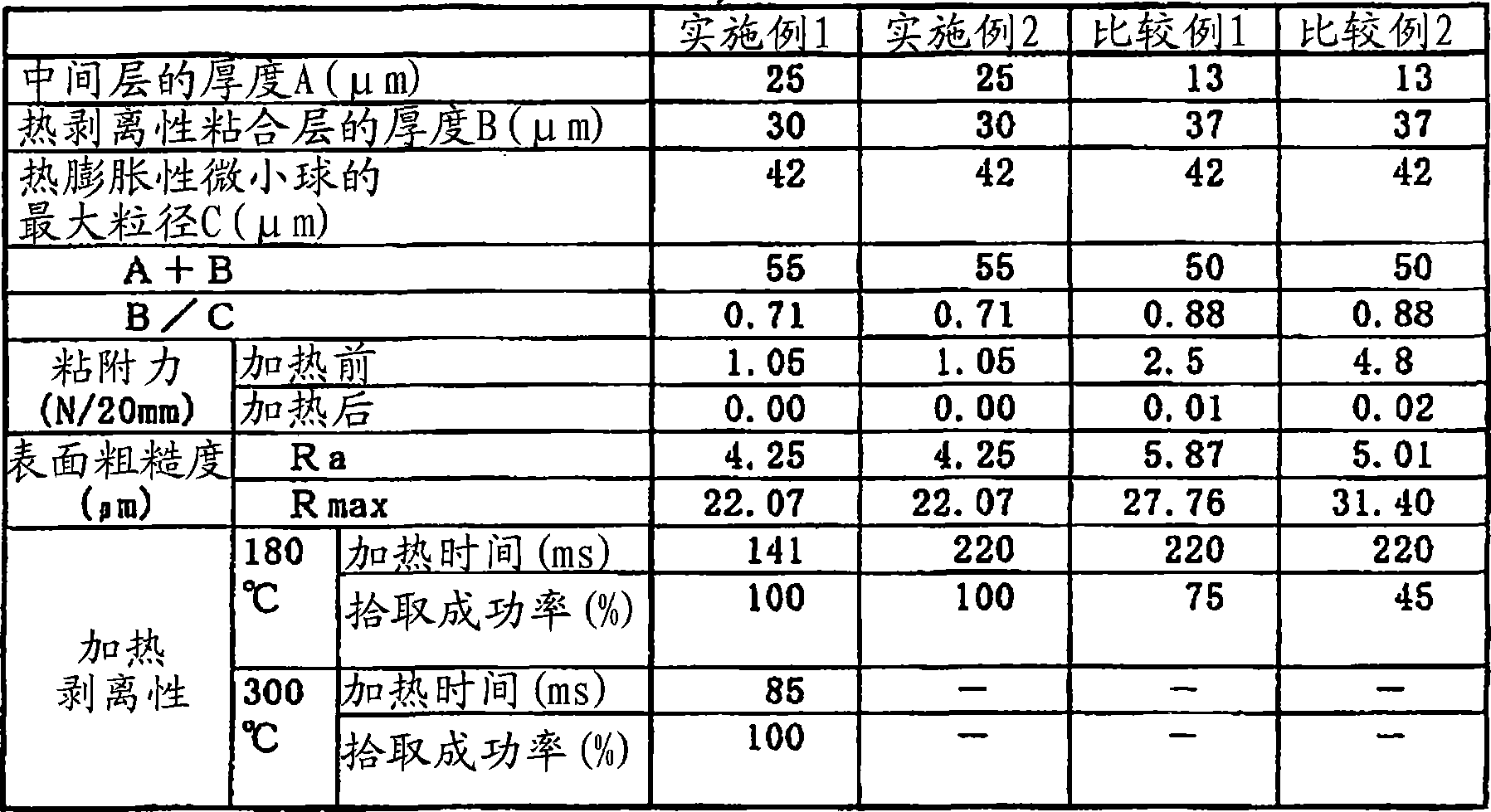

Embodiment 1

[0052] Be coated with 100 parts by weight of acrylic acid polymer A (acrylic acid polymer A) on the polyimide film base material (trade name " Capton H100 " of Du Pont chemical manufacture (du Pont Chemical, Du Pont-Toray), Tg300 ℃ or more) that thickness is 25 μ m. 2-ethylhexyl ester / ethyl acrylate / acrylic acid-2-hydroxyethyl ester (weight ratio: 50 / 50 / 4) copolymer), 3 parts by weight of isocyanate cross-linking agent (trade name " coronet-toL (colonateL )", a toluene solution of Nippon Polyurethane Industry Co., Ltd.) and dried to form an intermediate layer with a thickness of 25 μm.

[0053] In addition, a polyester film containing 100 parts by weight of the above-mentioned acrylic polymer A and 40 parts by weight of heat-expandable microspheres A (trade name "MazumotoMicrosoft F-301D (Matsumoto microspheres F- 301D)", Matsumoto Yushi-Seiyaku Co., Ltd. (Matsumoto Yushi-Seiyaku Co., Ltd.); expansion start temperature 90 ° C, median particle size (median size) 11.5 μm, maximu...

Embodiment 2

[0055] Except for using a polyethylene terephthalate base material (Tg68° C.) with a thickness of 38 μm instead of a polyamide base material with a thickness of 25 μm, the same operation was carried out as in Example 1 to obtain a total thickness of 93 μm. Heat-peelable adhesive sheet B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com