Lap equipressure gas absorption filtering equipment

A filter device and gas absorption technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large floor area, inconvenient maintenance, high cost, etc., achieve low cost and improve efficiency , The effect of increasing the adsorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

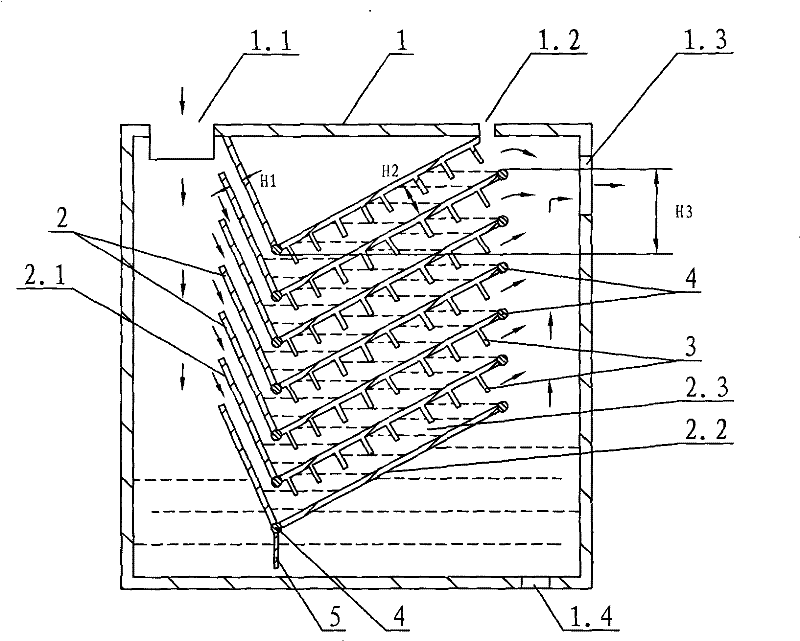

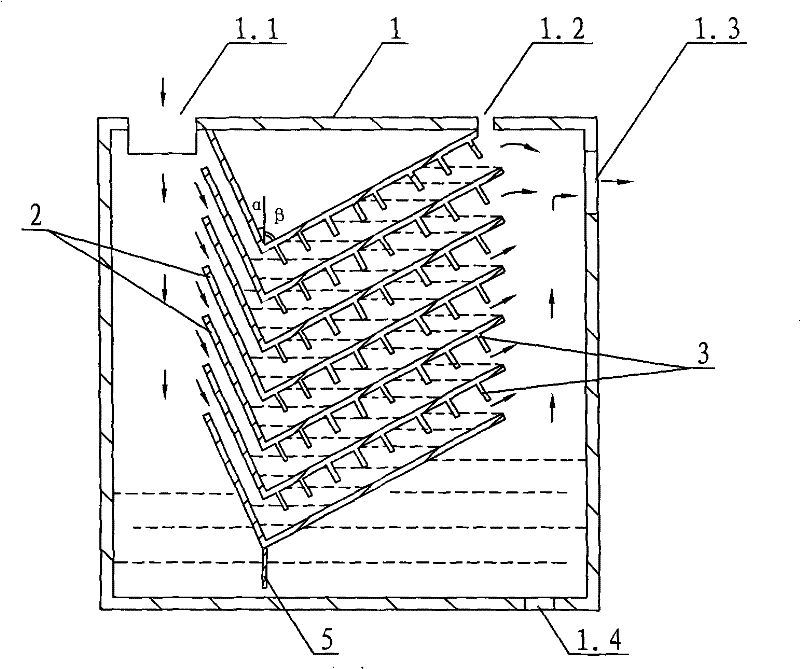

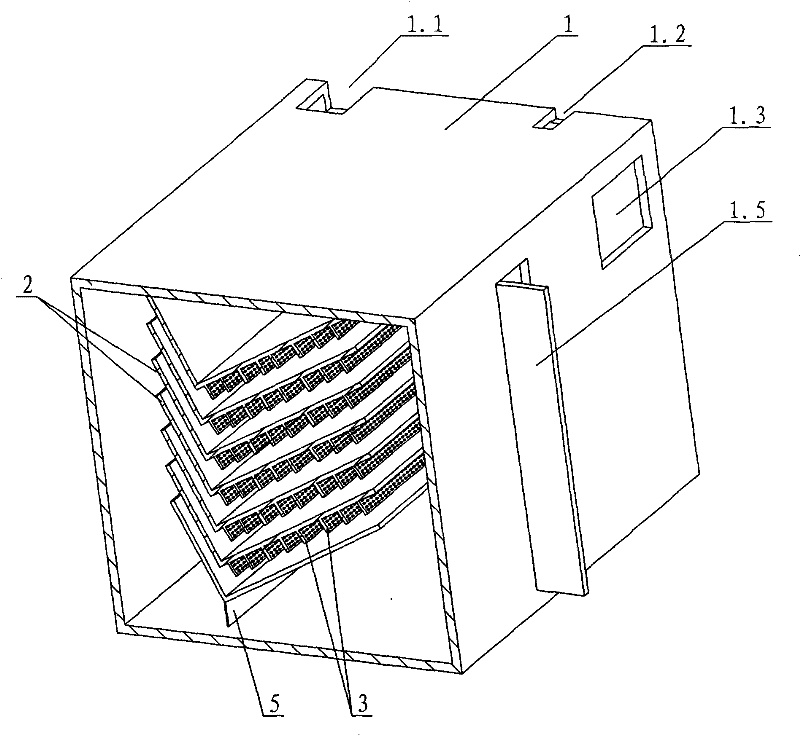

[0014] see Figure 1-Figure 3 , this stacked isobaric gas absorption filter device, the left side of the top wall of the box body 1 is provided with an air inlet hole 1.1, the right side is provided with a liquid inlet hole 1.2, the upper part of the right wall of the box body 1 is provided with an air outlet hole 1.3, and the bottom is provided with a discharge hole Liquid hole 1.4, multi-layer absorption filter layer 2 is arranged inside the box body 1, and each absorption filter layer 2 is arranged horizontally along the up and down direction, and the vertical distance H3 between the lowest point of the upper layer and the highest point of the adjacent air outlet of the next layer is equal , Several porous plates 3 are arranged in the absorption and filtration channel 2.3. The width of the porous plate is 1 / 2 to 3 / 4 of the distance between layers, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com