Interchangeable post-press processing system

A post-press processing and interchangeable technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as interchangeability, achieve the effects of reducing costs, increasing production speed, and improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

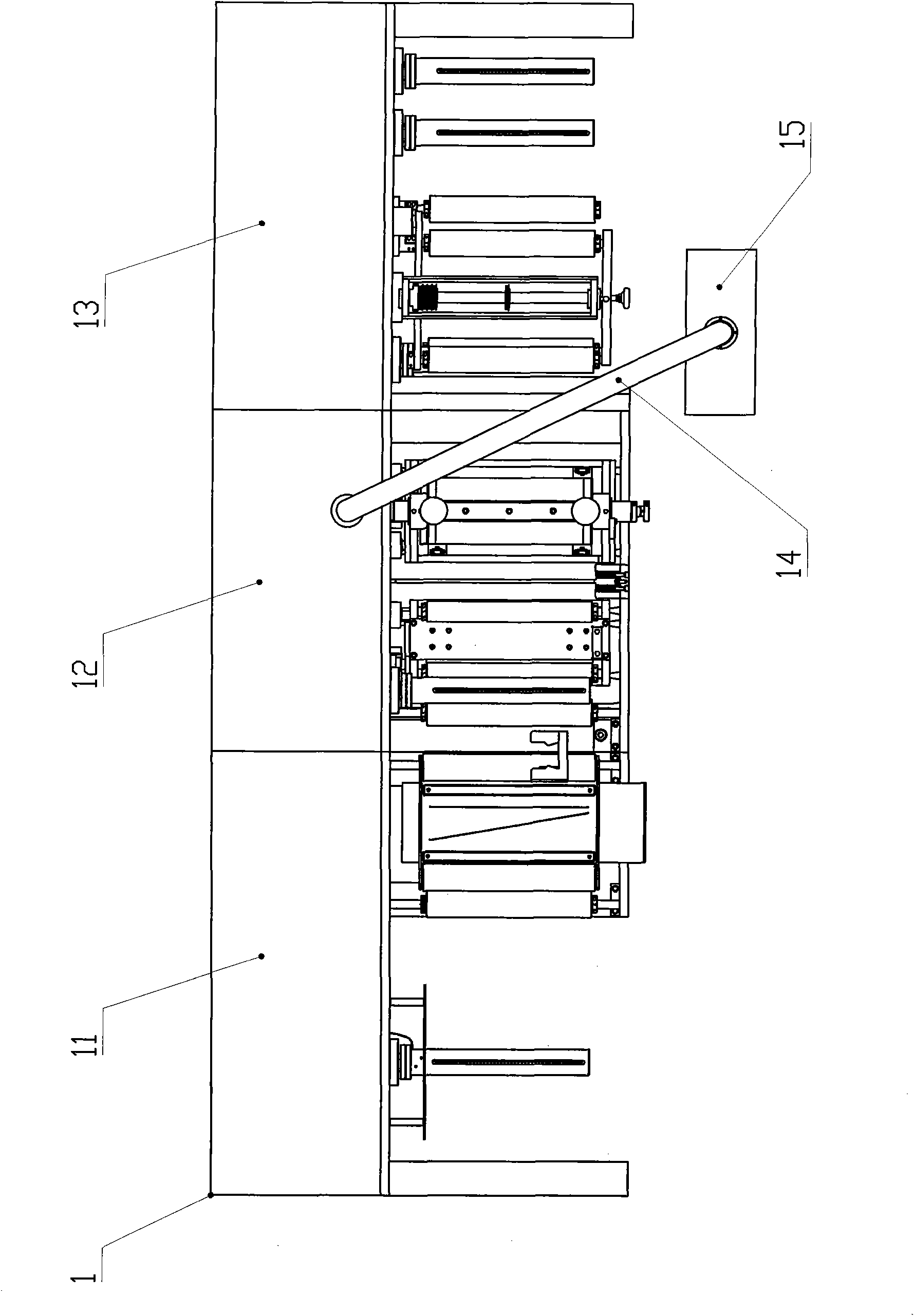

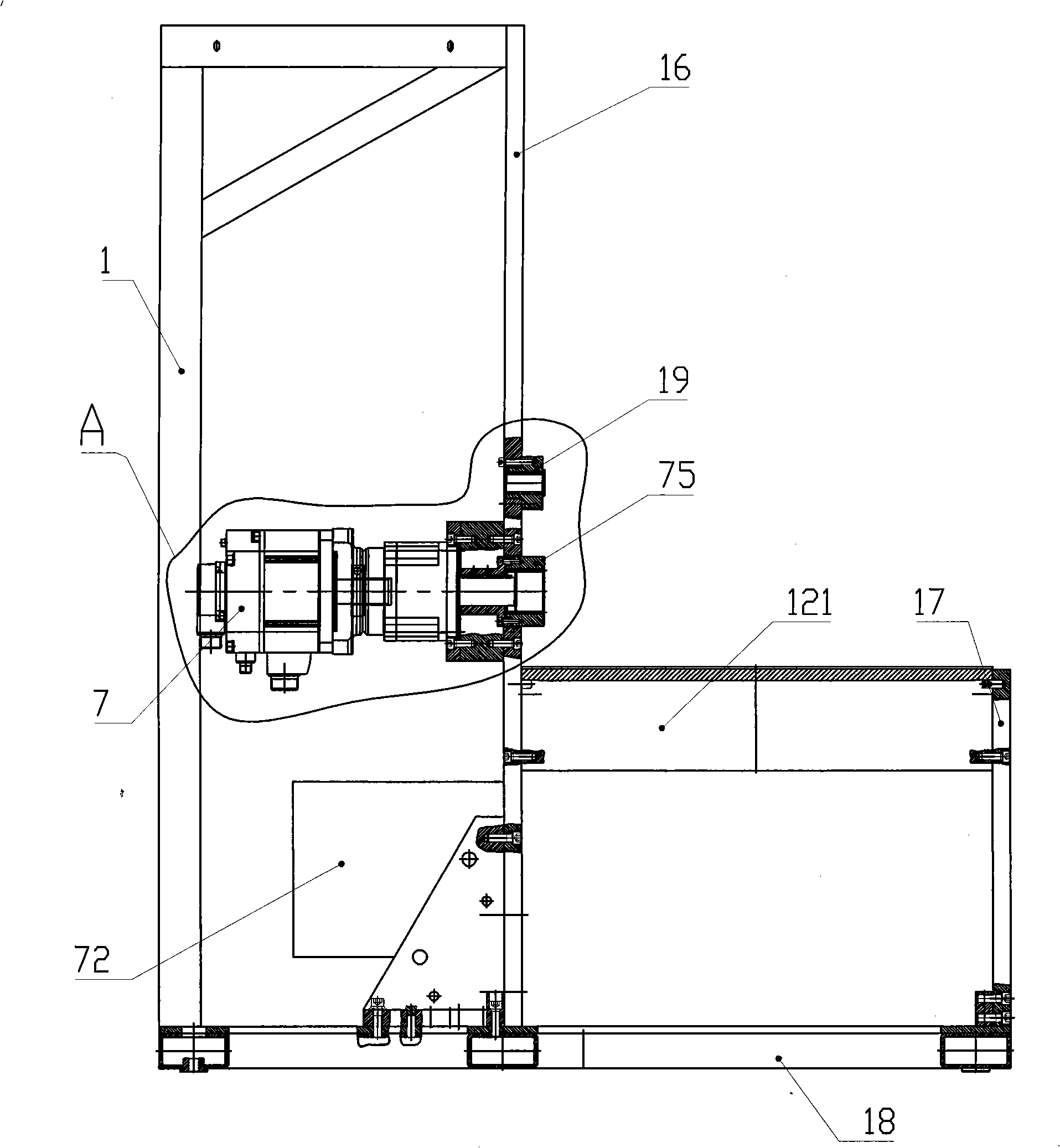

[0044] Embodiment 1: The interchangeable post-press processing system mainly includes a post-press processing platform 1, an unwinding device 2, a post-press processing device 3 and a winding device 4, and the post-press processing device 3 is a drum type post-press processing device. like figure 1 As shown, the post-press processing platform 1 is divided into: an unwinding part 11, a post-press processing part 12 and a rewinding part 13, and the unwinding part 11, the post-press processing part 12 and the rewinding part 13 are combined cabinets, The top of the post-press processing part 12 is also provided with an operation frame 14, and the operation frame 14 is rotationally connected with the post-press processing part 12, and the other end of the operation frame 14 is connected with an operation panel box 15, and the operation frame 14 is rotationally connected with the operation panel box 15, and the operation panel box 15 is the control panel of the interchangeable post...

Embodiment 2

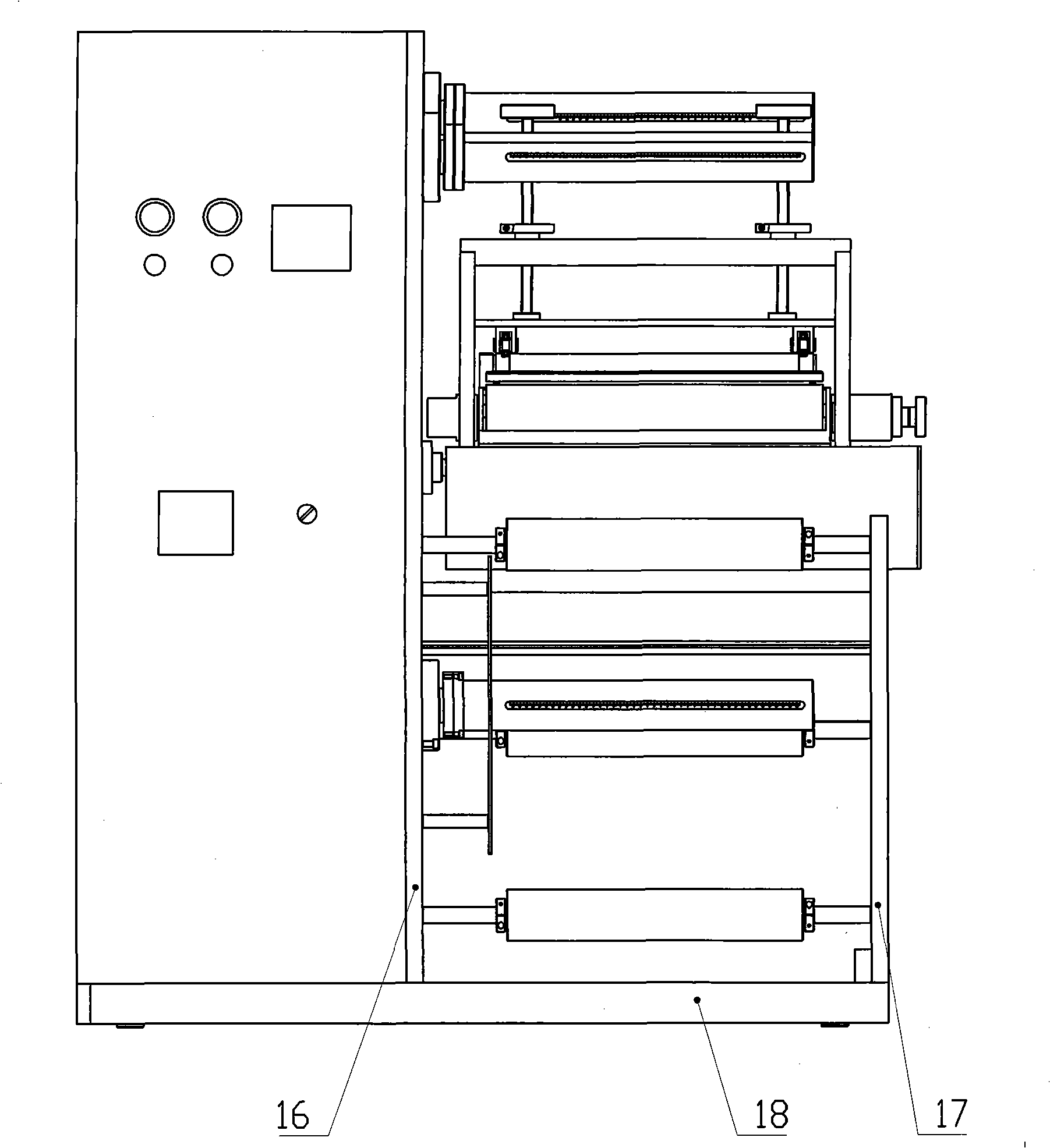

[0045] Embodiment 2: Based on Embodiment 1, since the unwinding part 11, the post-press processing part 12 and the winding part 13 are detachable combined cabinets, and the unwinding device 2 is installed in the unwinding part 11, an unwinding unit is formed; the post-press processing device 3 is installed on the post-press processing part 12 to form a post-press processing unit; the rewinding device 4 is installed on the rewinding part 13, A winding unit is formed. Therefore, the post-press processing unit can be arranged corresponding to the post-press processing process. combine Figure 10 and Figure 11 , the layout of the post-press processing technology in this embodiment is: winding device 2, deviation correcting device 5, traction device 6, glazing unit 100, cold stamping unit 200, embossing unit 300, die-cutting unit 400, cross-cutting unit 500 and closing unit Volume device4. The glazing unit 100, the cold stamping unit 200, the embossing unit 300, the die-cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com