Ship lock concentration and dispersion delivery system without calm section

A technology for decentralized water delivery and calming sections, applied in ship locks, ship lifting devices, buildings, etc., can solve the problems of large construction engineering volume and construction difficulty, inability to meet the energy dissipation requirements of ship locks, and large excavation depth of energy dissipation chambers at the head of locks, etc. problems, achieve the effect of shortening the water delivery time, increasing the initial opening speed, and facilitating construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

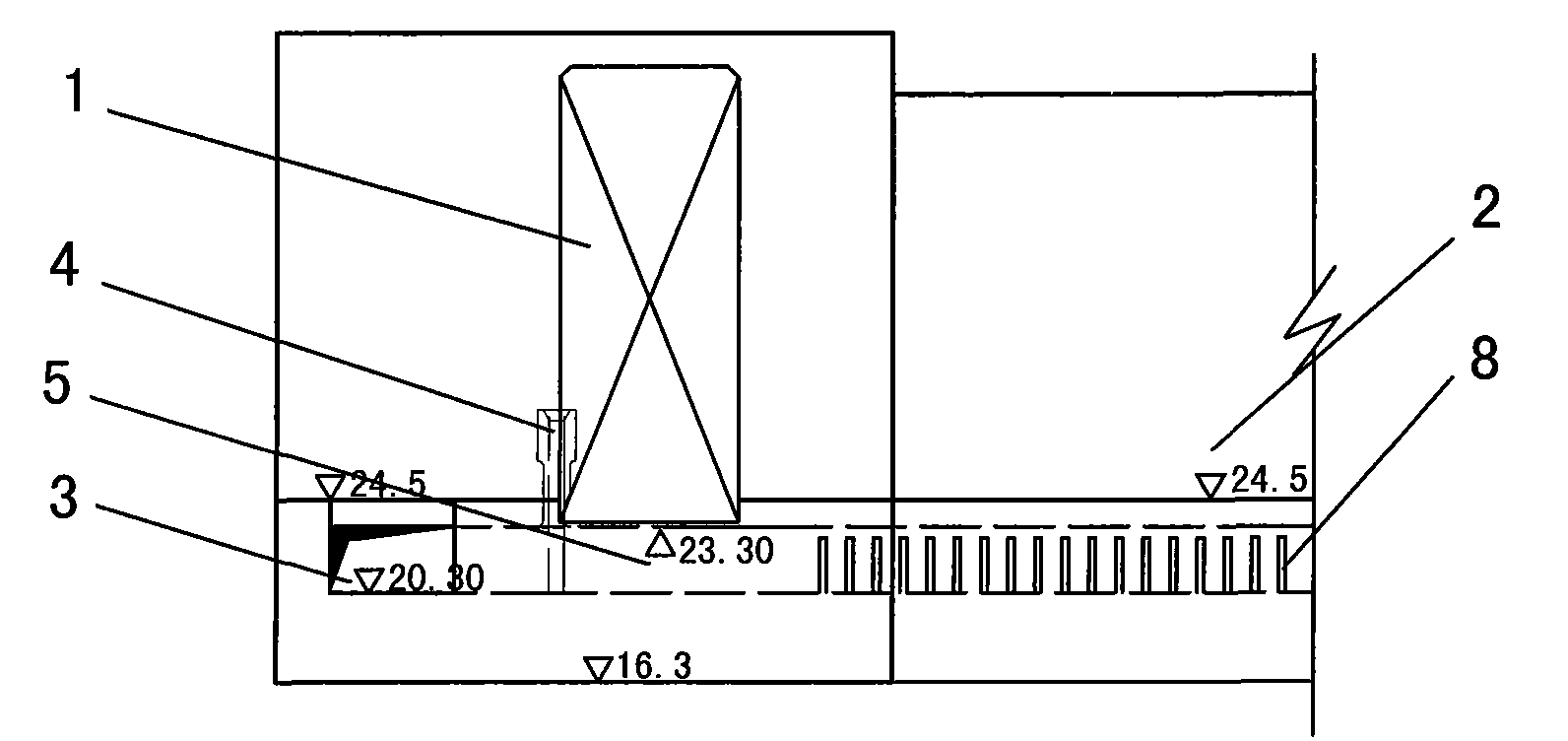

[0019] The effective size of the ship lock in this embodiment is 180m×23m×3.5m (length×width×threshold water depth), the designed maximum water head is 9.98m, the designed water delivery time is 8-10min, and the navigable 1000t-class double row single row one top two barge fleet. There is no curtain wall at the head of the ship lock to construct an energy dissipation room, and the water delivery system adopts a centralized and decentralized water delivery system without calming sections.

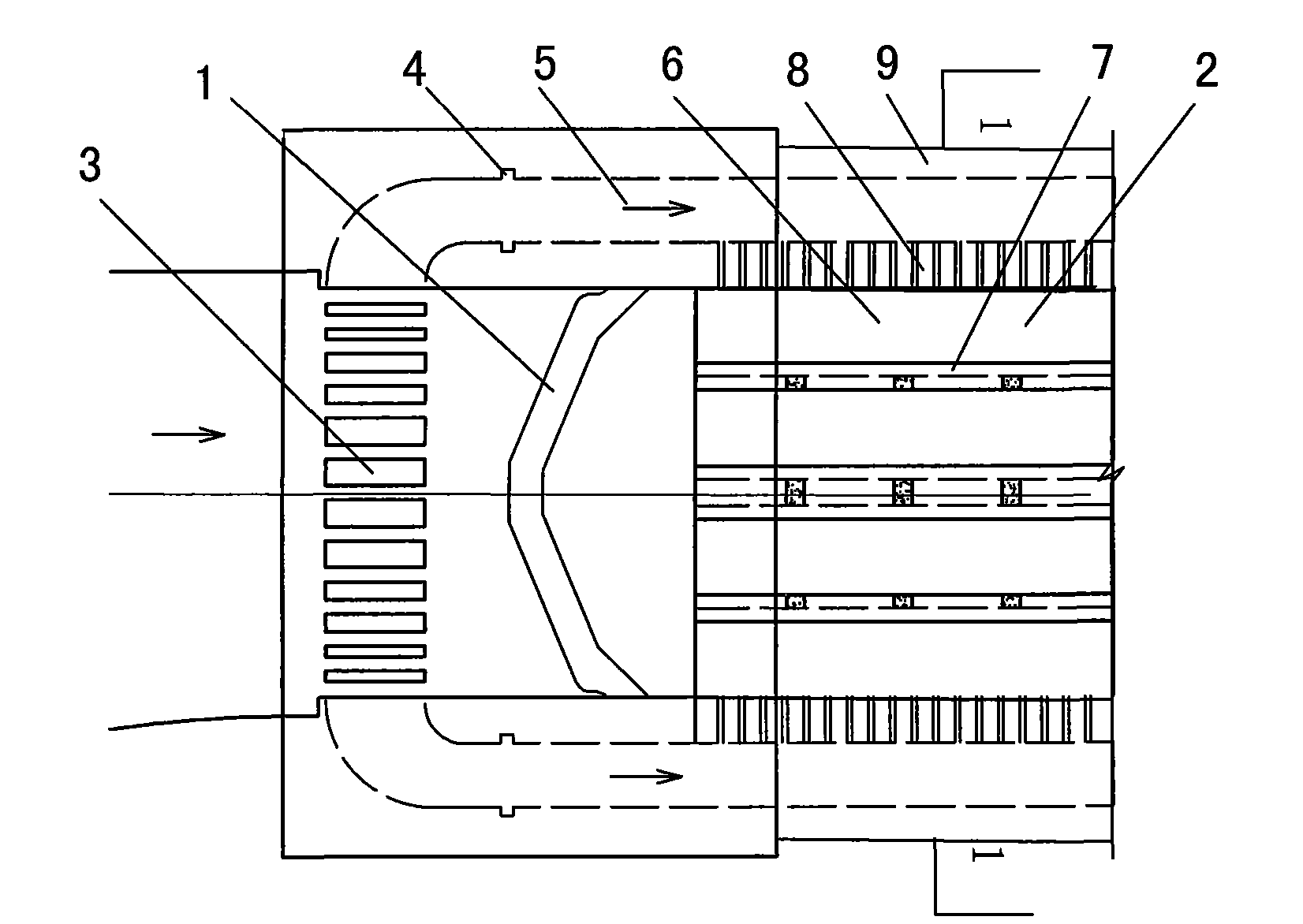

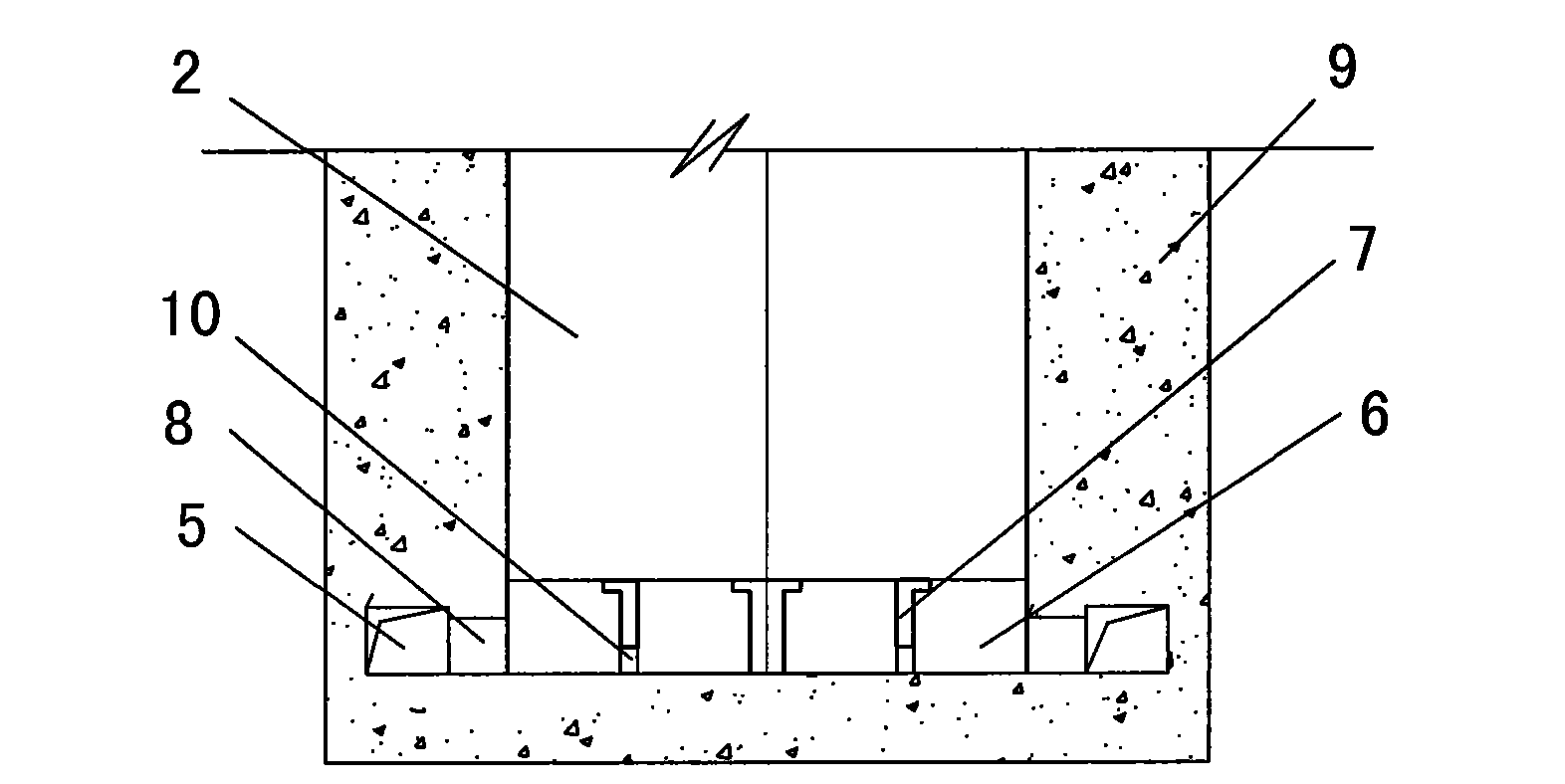

[0020] Such as Figure 1 to Figure 3 As shown, the centralized and decentralized water delivery system without sedation section includes a lock chamber 2 composed of an upstream gate 1 and a downstream gate (not shown in the figure). Upstream of the upstream gate 1 is provided a water inlet 3 across the lock. Both ends of the water inlet 3 respectively extend into the gate wall 9 at the lock chamber 2 through the water delivery corridor 5 controlled by the water delivery valve 4 . The slui...

Embodiment 2

[0024] The basic structure of the centralized and dispersed water delivery system without sedation section in this embodiment is similar to that of Embodiment 1 (see Figure 4 to Figure 6 ), the difference is that there are four longitudinally extending bottom water outlet energy dissipation sections in the lock chamber 2—the two sides are energy dissipation corridors 6', and the two in the middle are energy dissipation open ditches 6. The top plate of the energy dissipation corridor 6' is provided with top support holes 11 distributed at intervals. The water delivery corridors in the gate wall 9 communicate with the adjacent energy dissipation corridors 6' through the side branch holes 8 distributed at intervals on the gate wall 9 respectively. A retaining sill is provided between adjacent energy-dissipating open ditches 6, and the top of the retaining sill forms a T-shaped retaining wall; the energy-dissipating corridor 6' and the adjacent energy-dissipating open ditch 6 are...

Embodiment 3

[0027] The effective scale of the ship lock in this embodiment is 180m×23m×3.5m (length×width×water depth above the sill), the design maximum water head is 11.34m, the design water delivery time is 8-10min, and the control ship type is 2×1000t segmented barge Push fleet. The ship lock has a high water head, high hydraulic index, and a large navigable fleet. If the decentralized water delivery system is used, the engineering volume will be large, which will greatly increase the project investment; while the centralized water delivery system is more difficult, the layout should be Considering measures to reduce the initial wave force, a centralized and decentralized water delivery system without calming sections is adopted.

[0028] Depend on Figure 7 to Figure 9 It can be seen that the obvious difference from Embodiment 1 is that the two ends of the water inlet 3 respectively extend to the two longitudinally extending energy dissipation corridors 6' in the middle of the lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com