Water seepage prevention floor drain

A floor drain and water floor technology, which is applied in water supply installations, indoor sanitary pipeline installations, buildings, etc., can solve the problems of not dense gaps and affecting the use of lower-level residents, and achieve environmental protection installation, enhance waterproof effect, and prevent water seepage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

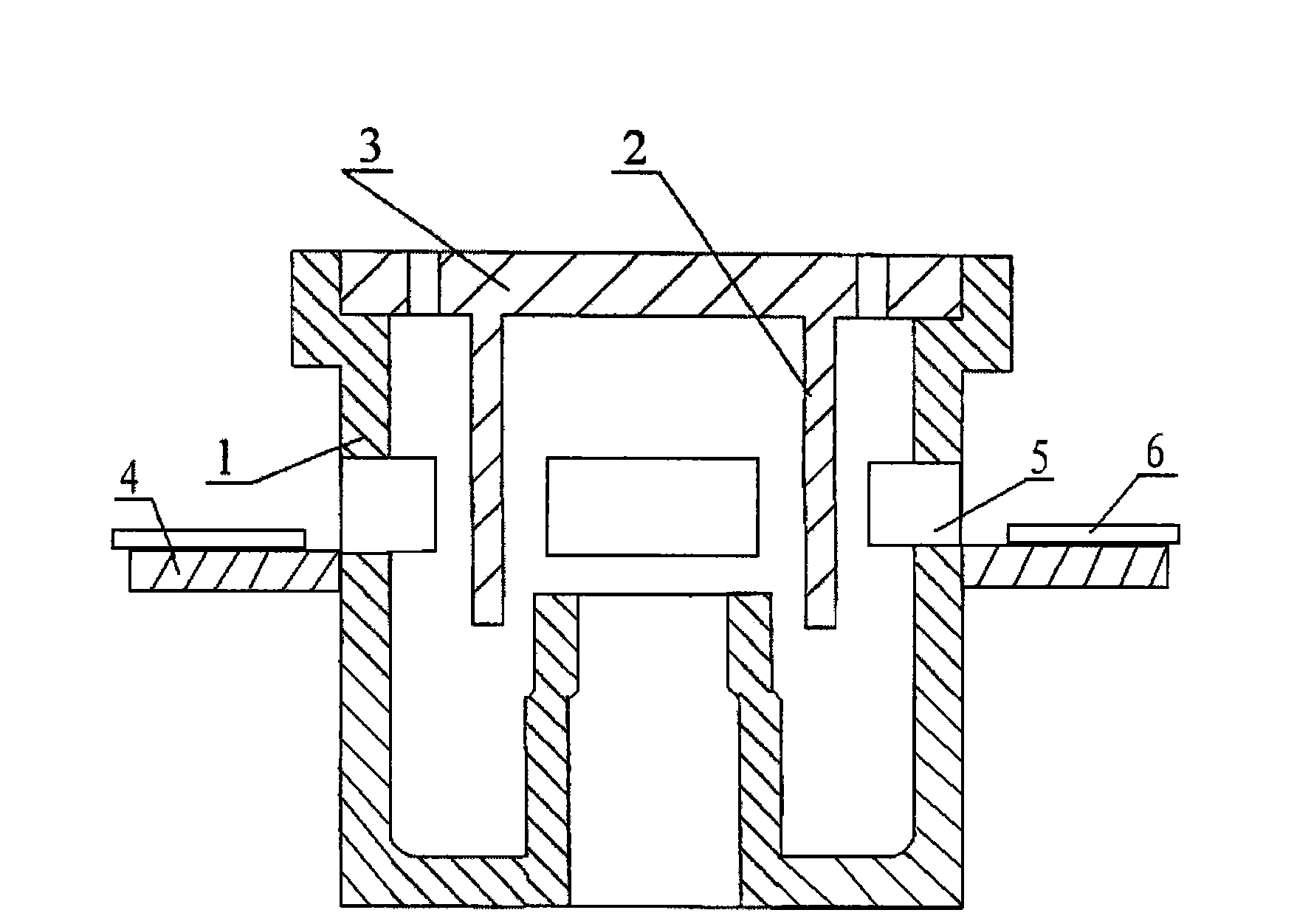

[0020] The anti-seepage water floor drain of the present embodiment comprises a floor drain body 1, a sealing bowl 2 inside the floor drain body 1, and an upper floor drain cover 3, and a circle surrounding the floor drain body 1 is provided on the periphery of the upper mouth of the floor drain body 1 down to 25mm. The water stop ring 4 protruding 25mm horizontally outwards, the outer circumference of the floor drain body 1 and the water stop ring 4 are closed and fixedly connected as one, and the shape of the water stop ring 4 is circular; on the water stop ring 4, along the The outer periphery of the floor drain body 1 is evenly provided with four drain outlets 5 of 25mm*15mm, and the water stop ring 4 is at an inclined angle relative to the outer wall of the floor drain body 1, with the outside high and the inside low; the height of the connection between the water stop ring 4 and the floor drain body 1 is located on the ground Below the position of the waterproof layer 6 l...

Embodiment 2

[0024] The difference between this embodiment and embodiment 1 is that it includes a floor drain body 1 , a sealing bowl 2 inside the floor drain body 1 and an upper floor drain cover 3 , and the shape of the water stop ring 4 is square.

[0025] In the anti-seepage water floor drain of the above embodiments, a water-stop ring is installed on the existing floor drain, which further enhances the waterproof effect, and effectively prevents water seepage in the waterproof layer and conducts drainage and discharge for seepage water, which is environmentally friendly and easy to install.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com