Injector gas and air preheat gas burner for carbon anode/cathode roasting oven

A gas burner and air preheating technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of increased product cost, more combustible gas, unfavorable temperature rise, etc., to reduce the pulsating working frequency, mix Completely sufficient, overcoming the effect of cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

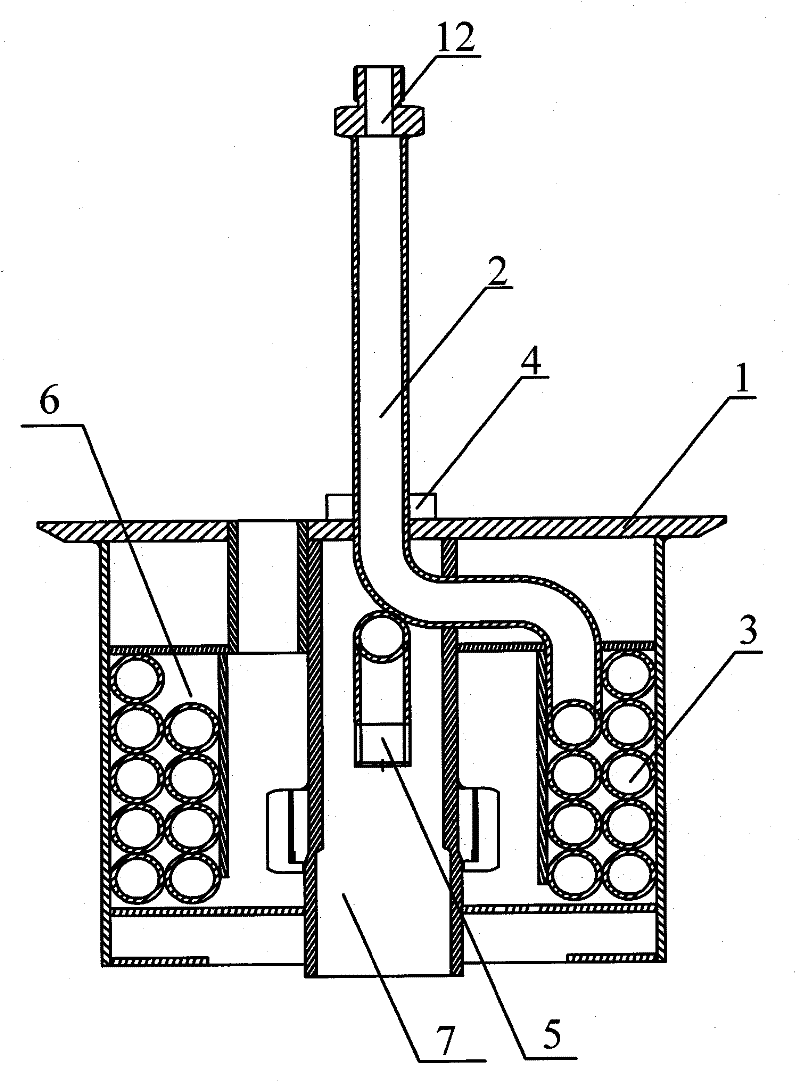

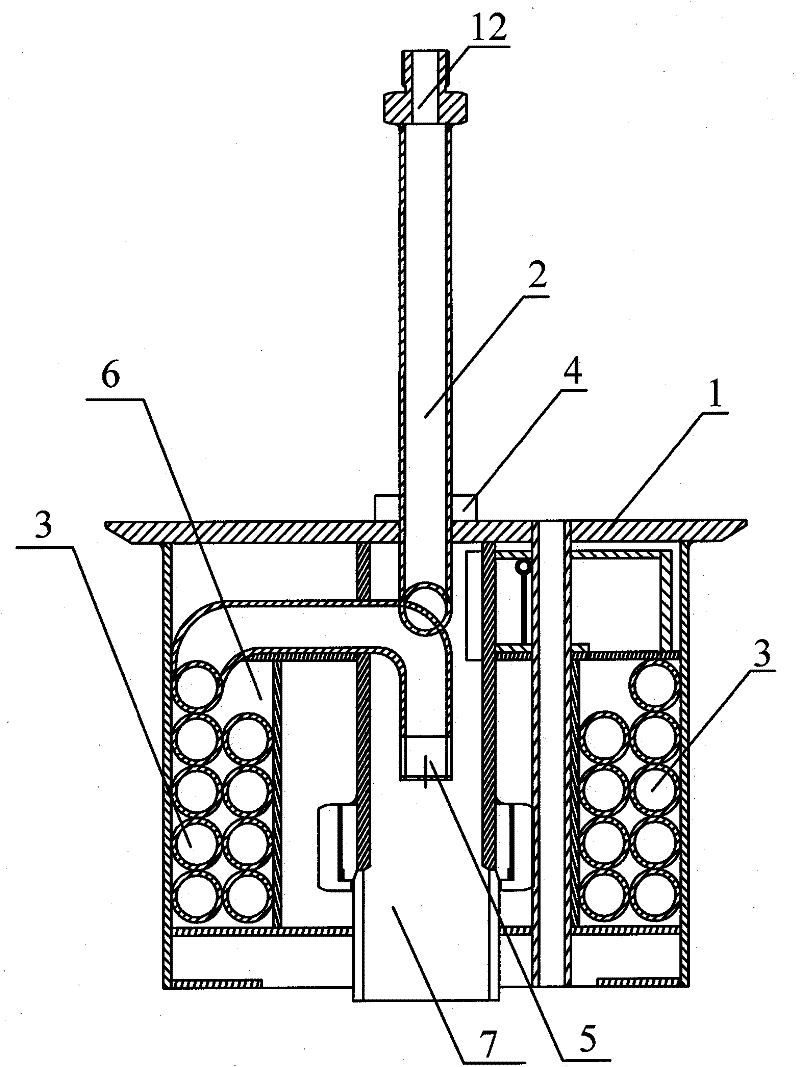

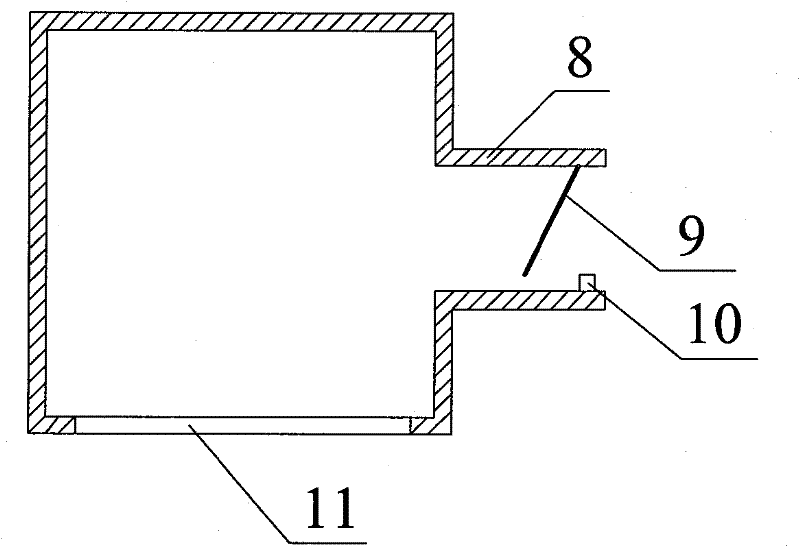

[0019] Such as figure 1 , 2 As shown, the gas inlet pipe 2 used for transporting natural gas or coal gas in the present invention is vertically fixed on the furnace base 1 of the carbon anode or cathode roasting furnace, and a part of the gas inlet pipe 2 is located outside the furnace base 1, and is connected with a The valve 12 is connected so as to control the flow and velocity of the gas passing through the intake pipe 2 through the valve 12 . The other part of the air intake pipe 2 is located inside the furnace base 1 and is connected to the air intake end of the coil device 3 located inside the furnace base 1 .

[0020] Since the gas temperature of the natural gas or coal gas supplied from the gas source is normal temperature or lower than the ambient temperature, when these gases enter the fire channel 7 (furnace chamber) of the burner, relative to the temperature in the furnace of more than 1150°C It will have a large adverse effect on temperature rise, which will ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com