Boiler pump motor having one-way sealing property stuffing box

A one-way sealing, furnace water pump technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of failure of the guide bearing at the pump end, easy bending of the shaft extension, etc., to prevent the insulation from burning out and prevent the bearing from bending. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

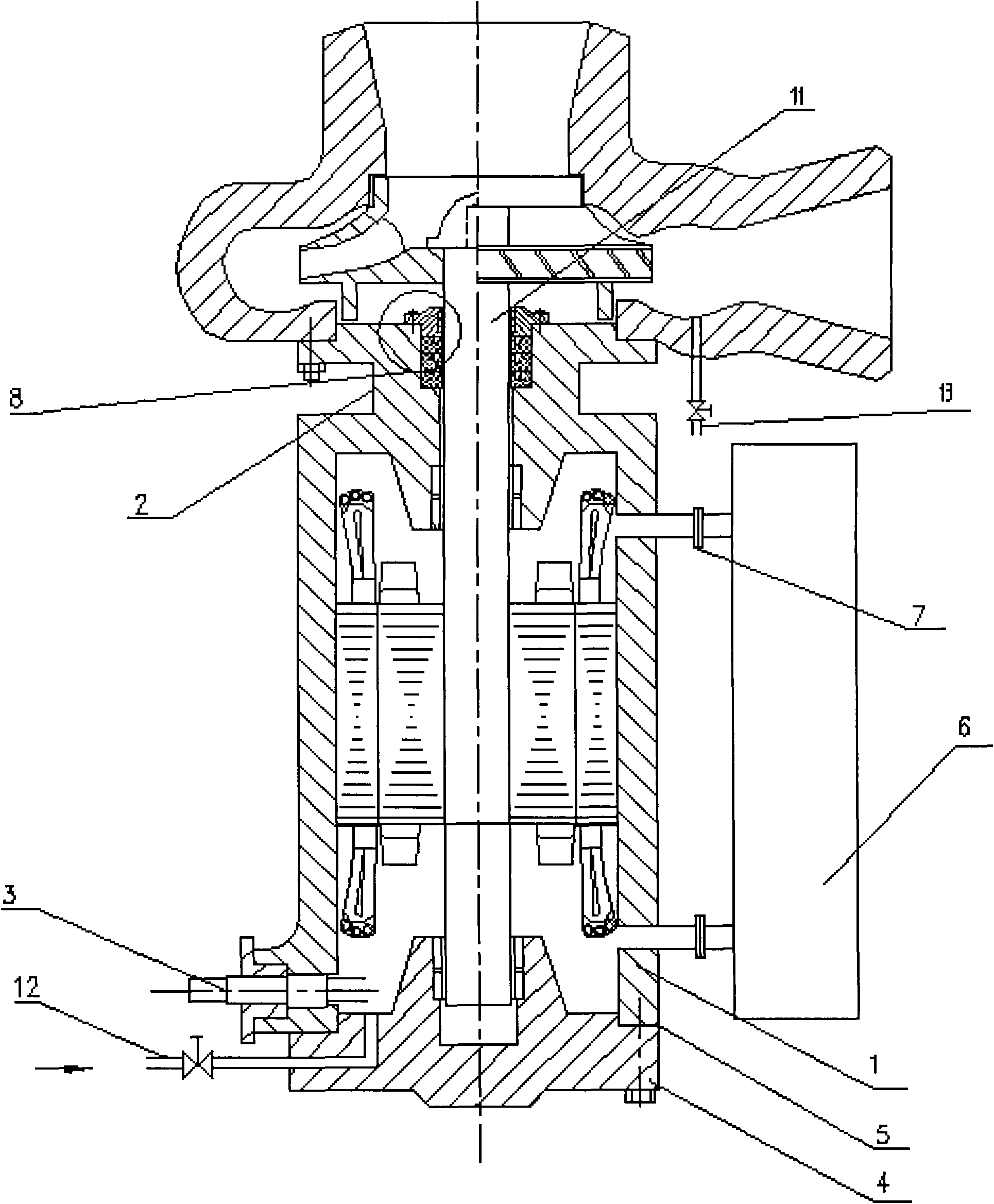

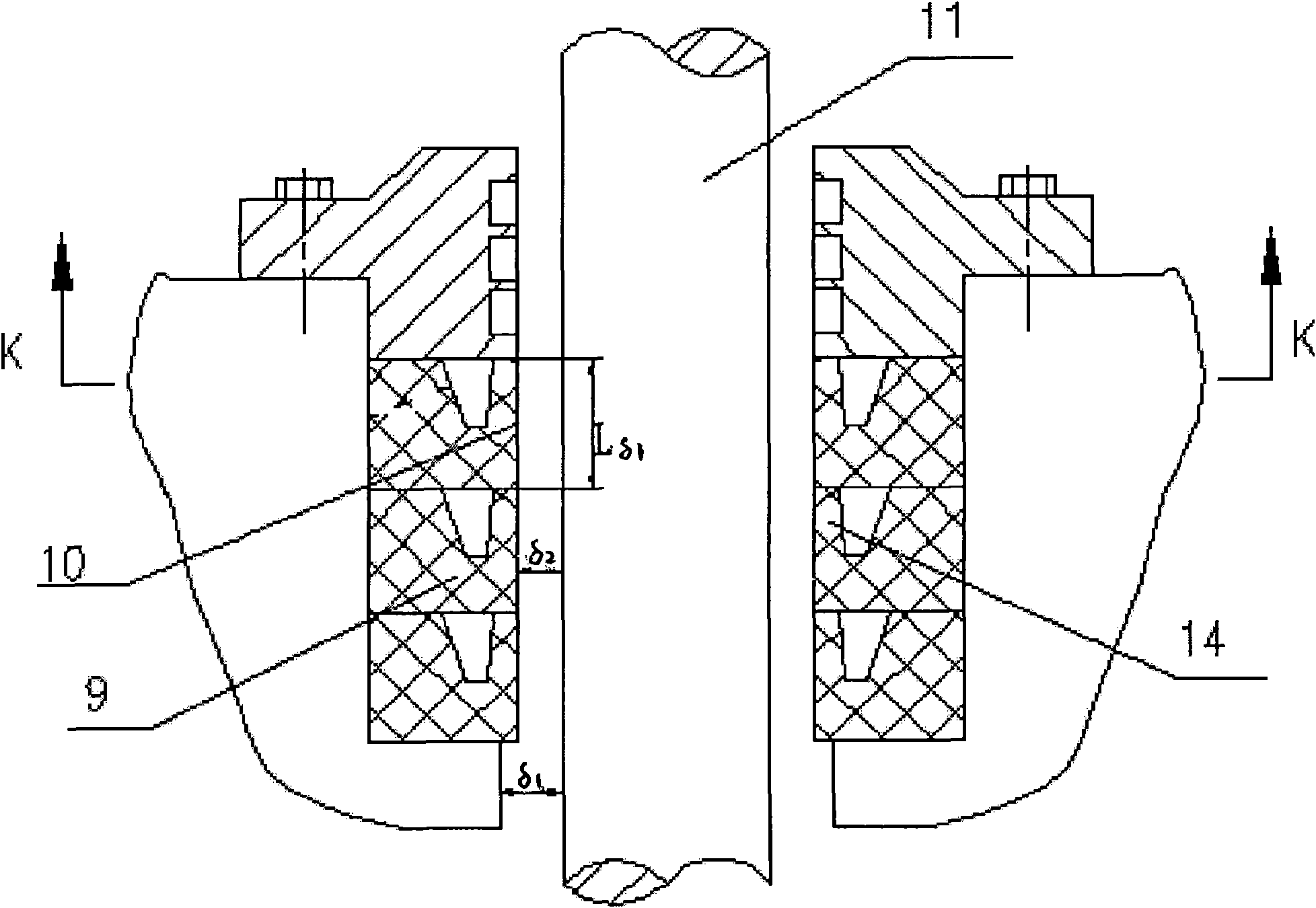

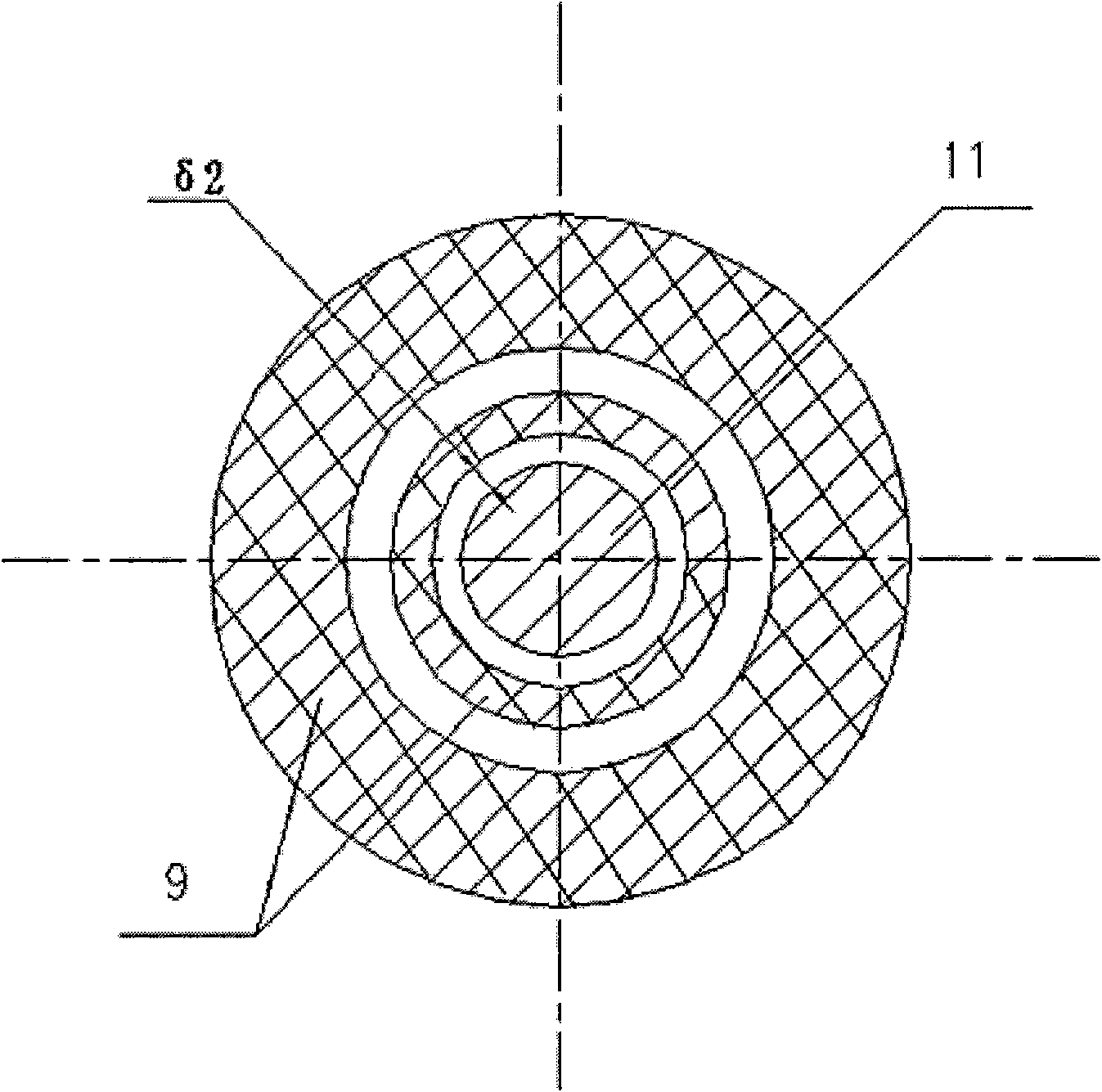

[0021] see figure 1 The boiler water pump motor with one-way sealing performance stuffing box includes a motor and a boiler water pump. The motor includes a sealed container 1, a stator, a rotor and a shaft 11. The extended end of the shaft 11 is connected to the boiler water pump. The connection between the motor and the boiler water pump At Hot Neck 2. The shaft at the hot neck 2 is the shaft extension 8, and three special-shaped sealing rings 9 are set on the shaft 11 of the shaft extension 8; the outer axial end surface of each special-shaped sealing ring 9 is provided with grooves, and the special-shaped sealing The cross-section of the groove on the ring 9 is an inverted trapezoid, and the gap between the inner cylindrical surface 10 of the special-shaped sealing ring 9 and the shaft 11 is the sealing gap δ 2 , sealing gap δ 2 0.2-0.25 mm, see figure 2 with image 3 .

[0022] The technical requirements of the special-shaped sealing ring 9 are: working temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com