Field emission cold cathode

A cold cathode and cathode technology, applied in the field of vacuum tubes, can solve the problems of reducing energy efficiency of heaters, increasing system volume, weight and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

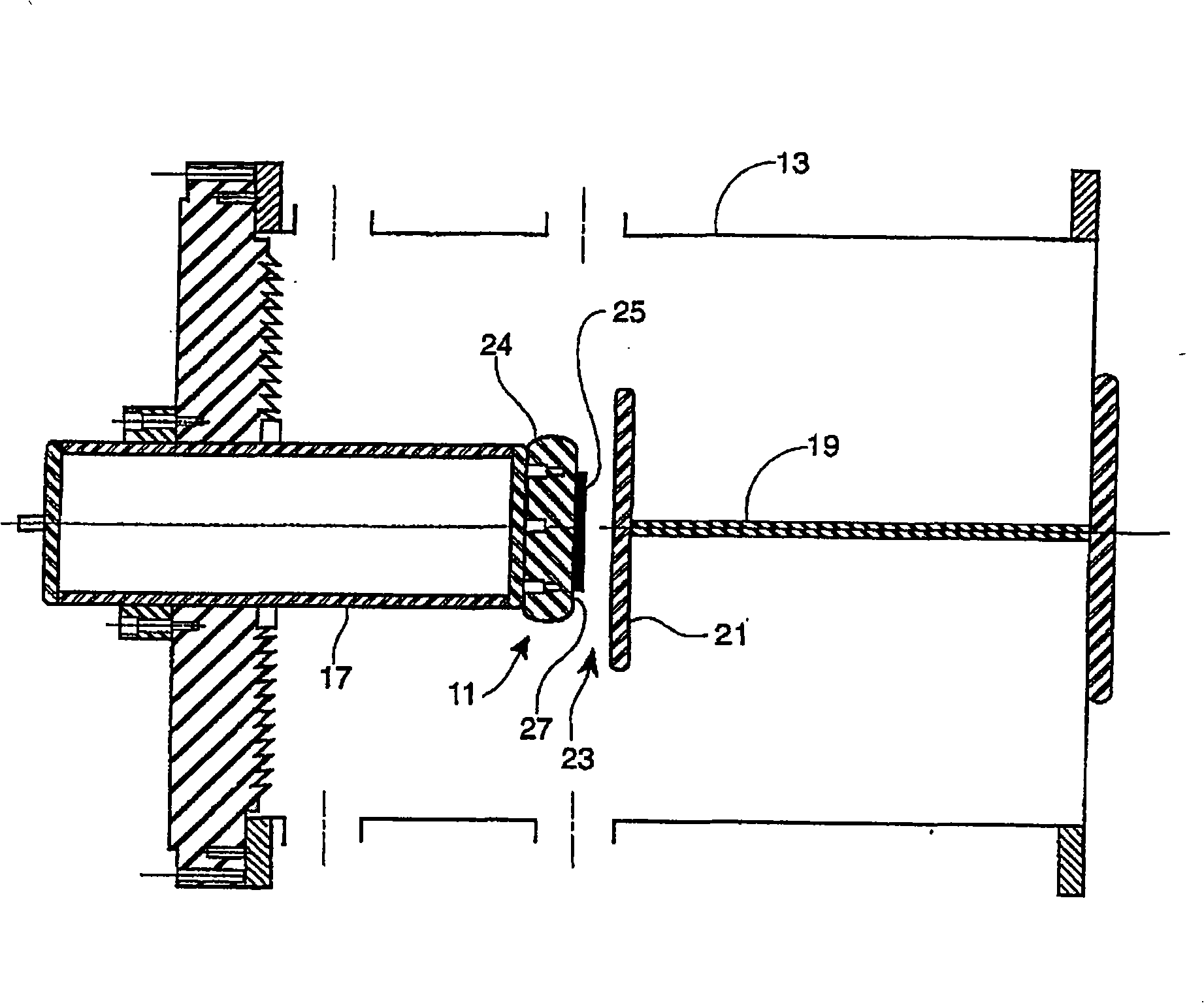

[0015] The accompanying drawing is a schematic diagram of experimental equipment for testing the field emission cold cathode 11 of the present invention, and shows a cross section of the cold cathode 11 . The apparatus includes a vacuum chamber 13 and a cathode mounting table 17 . The rod 19 protrudes into the vacuum chamber 13 and can be retracted and extended relative to the cold cathode 11 . Anode 21 is mounted on one end of rod 19 . Gap 23 is the distance separating cathode 11 and anode 21 and is adjustable by retracting or extending rod 19 .

[0016] The cold cathode 11 consists of a high voltage bushing 24 , a carbon velvet material 25 and a cathode surface 27 . As will be described in detail later, the carbon velvet material 25 is treated with a low work function cesium salt and bonded to the cathode surface 27 . The carbon velvet material 25 consists of high aspect ratio carbon fibers embedded perpendicular to the matrix material. Specific materials of this type ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap