Manufacture method for layer-adding circuit board

A manufacturing method and circuit board technology, applied in circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low wiring density, complex process, and inability to meet users, so as to reduce manufacturing costs and reduce the thickness of finished boards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

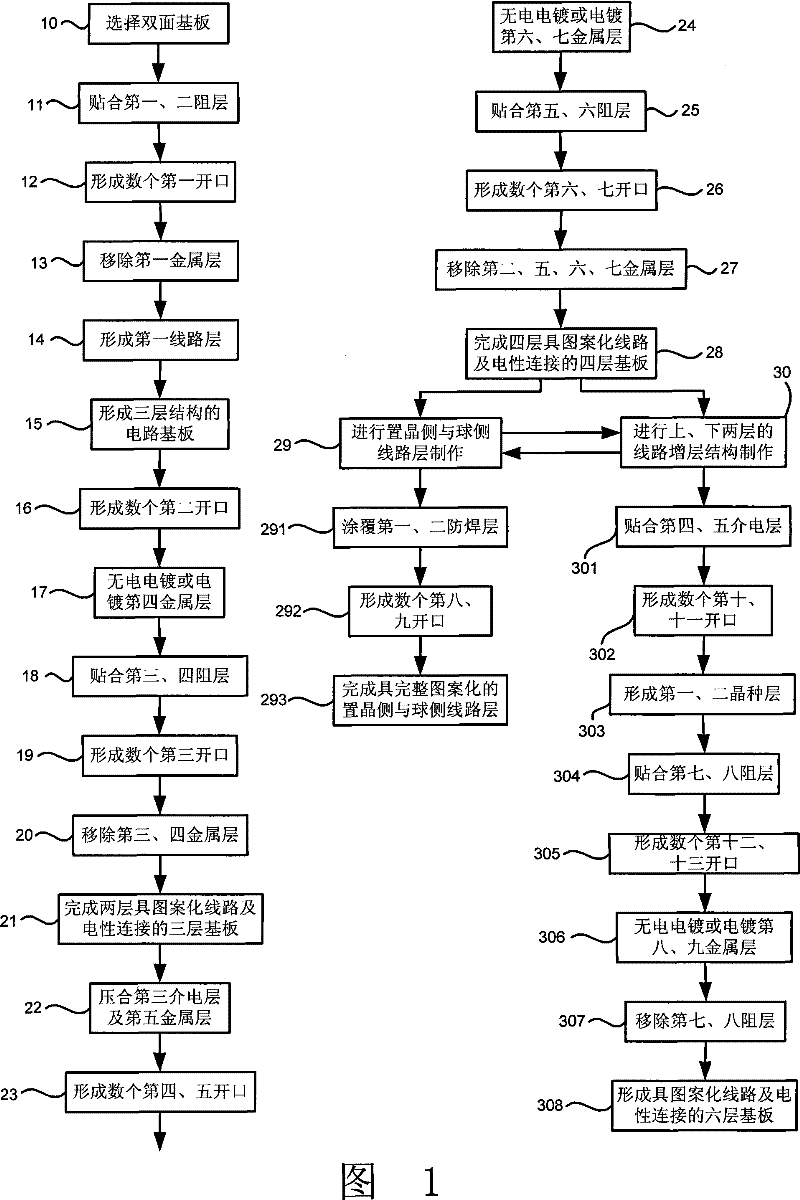

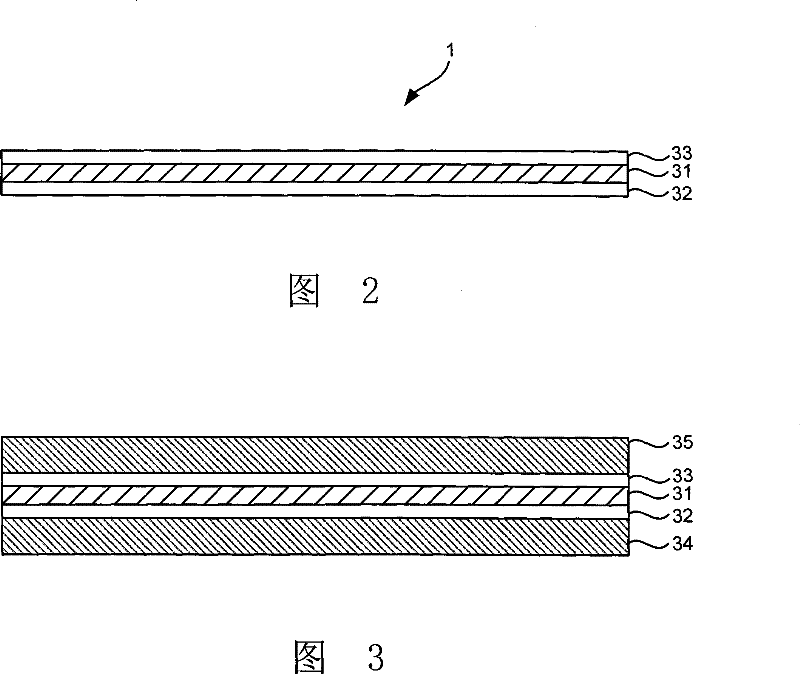

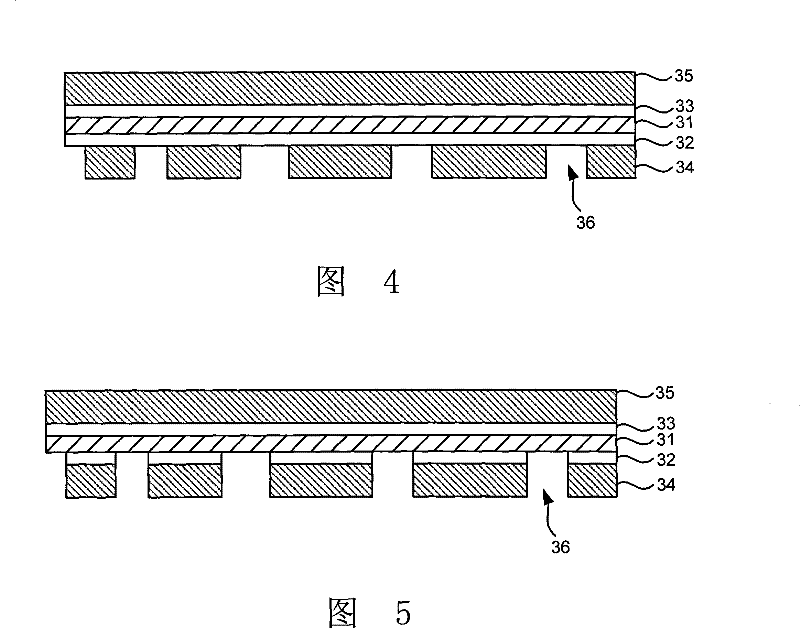

[0114] see Figure 1 to Figure 31 Shown are the schematic diagram of the production process of the present invention, the schematic cross-section of the double-sided substrate of the present invention, and the schematic cross-section of the two-layer substrate of the present invention. Figure 1 , The schematic cross-section of the two-layer substrate of the present invention Figure II , The schematic cross-section of the two-layer substrate of the present invention Figure three , The schematic cross-section of the two-layer substrate of the present invention Figure four , The schematic cross-section of the three-layer substrate of the present invention Figure 1 , The schematic cross-section of the three-layer substrate of the present invention Figure II , The schematic cross-section of the three-layer substrate of the present invention Figure three , The schematic cross-section of the three-layer substrate of the present invention Figure four , The schematic cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com