INP wafer thinning and polishing process method

A technology of thinning and polishing, process method, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problems that the N-side metal cannot be operated at one time, the back of the wafer is rough, and the processing cost is high. Achieve the effects of improving the warping problem, smoothing the wafer surface, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

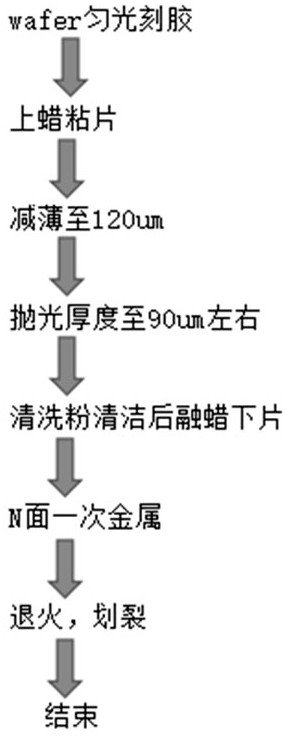

[0038] (1) Wafer the wafer with photoresist, thin it to 120um, and measure the thickness.

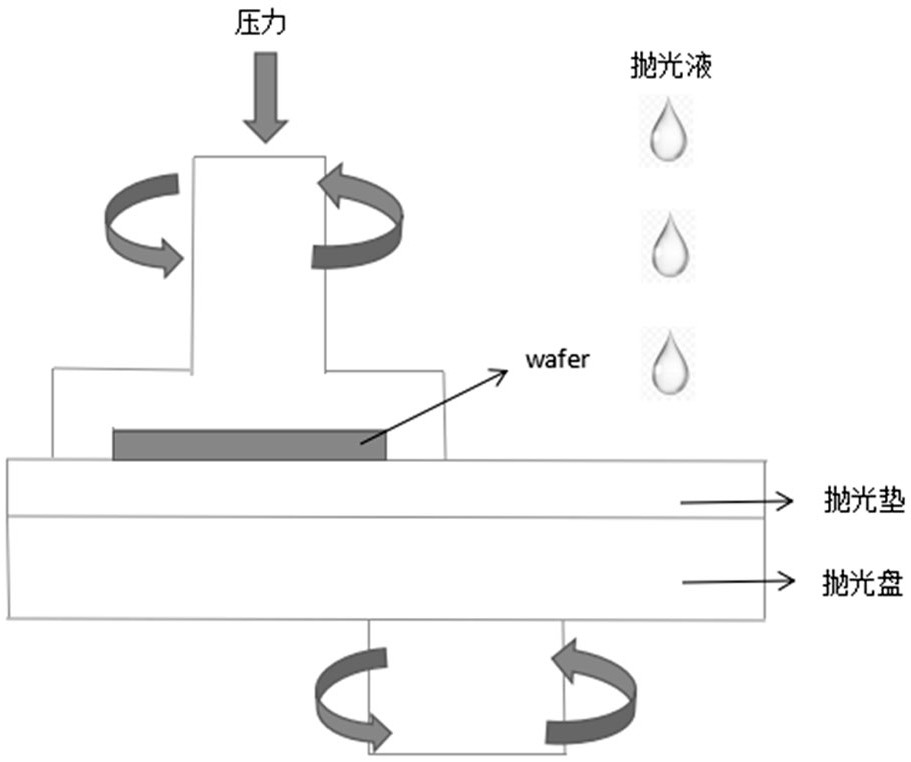

[0039] (2) Remove the wafer from the thinned glass plate, replace it with a polishing plate, and contact the wafer with the polishing pad.

[0040] (3) Polishing for 15 minutes, polishing the wafer to 80-100um, using alumina polishing liquid ASCP2002, the peristaltic pump controls the liquid all the time, the total polishing flow is 250-300ml, the polishing temperature is 25°C, and the polishing pressure is 230g / cm 2 .

[0041] (4) Use absorbent cotton dipped in cleaning powder: water = 100:1 solution for cleaning, then blow dry with nitrogen, and remove the film.

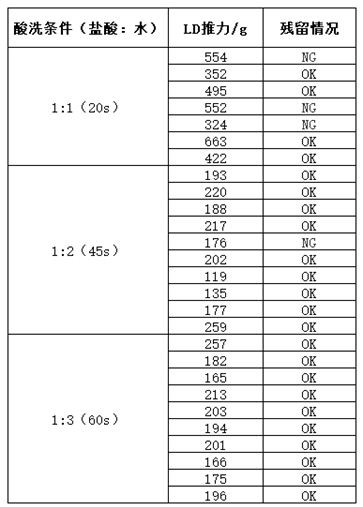

[0042] (5) Wash with hydrochloric acid: water = 1:1 for 20s, and carry out N-side metal coating.

[0043] (6) Annealing, and finally slicing the cleavage strip.

Embodiment 2

[0044] Embodiment 2, embodiment 3 are similar to embodiment 1, and the difference lies in the pickling condition after the next tablet:

[0045] In Example 2, in step (5), use hydrochloric acid: water = 1:2 to clean for 45s, and perform N-face metal coating.

[0046] In Example 3, in step (5), hydrochloric acid: water = 1:3 was used for cleaning for 60s, and N-face metal coating was performed.

[0047] Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com