A kind of reinforced nylon 6 material resistant to warping deformation and preparation method thereof

A technology of nylon and warping, which is applied in the field of chemical materials, can solve problems such as single method and change the degree of warping and warping of nylon 6 composite materials, and achieve the effects of low process cost, making up for anisotropy problems, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

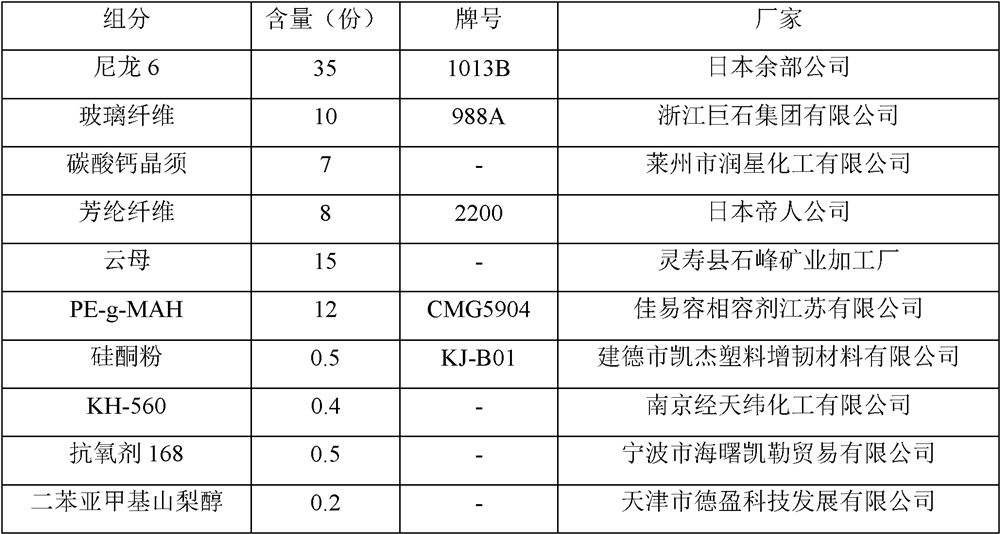

[0042] Example 1 Reinforced nylon 6 material and its preparation

[0043]

[0044] The viscosity of the nylon 6 is 2.6;

[0045] The glass fiber is an alkali-free and untwisted continuous glass fiber with an average diameter of 8 μm;

[0046] The calcium carbonate whiskers have an average diameter of 0.3 μm and an average length of 50 μm;

[0047] The average length of the aramid fibers is 2 mm, and the average diameter is 15 μm;

[0048] The mica is a natural mineral powder with an average particle size of 20 μm.

[0049] Preparation:

[0050] (1) Surface treatment of whiskers: Mix calcium carbonate whiskers at 1800rpm for 3.5min to open aggregates, then add 10% KH-550 ethanol solution while stirring at the same speed, mix and stir for 8min, and dry at 60°C for 12h ,spare.

[0051] (2) Surface treatment of aramid fiber: After washing the aramid fiber three times with absolute ethanol, dry it at 60°C for 3 hours, add the remaining 10% KH-550 ethanol solution, dry it at 6...

Embodiment 2

[0054] Example 2 Reinforced nylon 6 material and its preparation

[0055]

[0056] The viscosity of the nylon 6 is 2.5;

[0057] The glass fiber is an alkali-free and untwisted continuous glass fiber with an average diameter of 12 μm;

[0058] The calcium carbonate whiskers have an average diameter of 0.5 μm and an average length of 60 μm;

[0059] The average length of the aramid fiber is 1.0 mm, and the average diameter is 15 μm;

[0060] The mica is a natural mineral powder with an average particle size of 80 μm.

[0061] Preparation:

[0062] (1) Surface treatment of whiskers: Calcium carbonate whiskers were mixed at 1800rpm for 4 minutes to open the aggregates, then added 10% KH-550 ethanol solution while stirring at the same speed, mixed and stirred for 8 minutes, and dried at 70°C for 11 hours. spare.

[0063] (2) Surface treatment of aramid fibers: After washing the aramid fibers twice with absolute ethanol, dry them at 70°C for 2.5 hours, add the remaining 10%...

Embodiment 3

[0066] Example 3 Reinforced nylon 6 material and its preparation

[0067]

[0068] The viscosity of the nylon 6 is 2.0;

[0069] The glass fiber is an alkali-free and untwisted continuous glass fiber with an average diameter of 10 μm;

[0070] The calcium carbonate whiskers have an average diameter of 0.8 μm and an average length of 100 μm;

[0071] The average length of the aramid fibers is 0.6 mm, and the average diameter is 10 μm;

[0072] The mica is a natural mineral powder with an average particle size of 5 μm.

[0073] Preparation:

[0074] (1) Surface treatment of whiskers: Calcium carbonate whiskers are mixed at 2000rpm for 3 minutes to open the aggregates, then add 8% KH-560 ethanol solution while stirring at the same speed, mix and stir for 10 minutes, and dry at 75°C for 10 hours. spare.

[0075] (2) Surface treatment of aramid fiber: After washing the aramid fiber twice with absolute ethanol, dry it at 75°C for 2 hours, add the remaining 8% KH-560 ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com