Copper core layer multilayer packaging substrate manufacturing method

A technology for encapsulating substrates and manufacturing methods, which is applied in the directions of multilayer circuit manufacturing, metal core circuit manufacturing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as difficulty in making copper core substrates, inability to meet users, and low wiring density, and achieve Improve the warping problem, simplify the packaging process, and improve the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

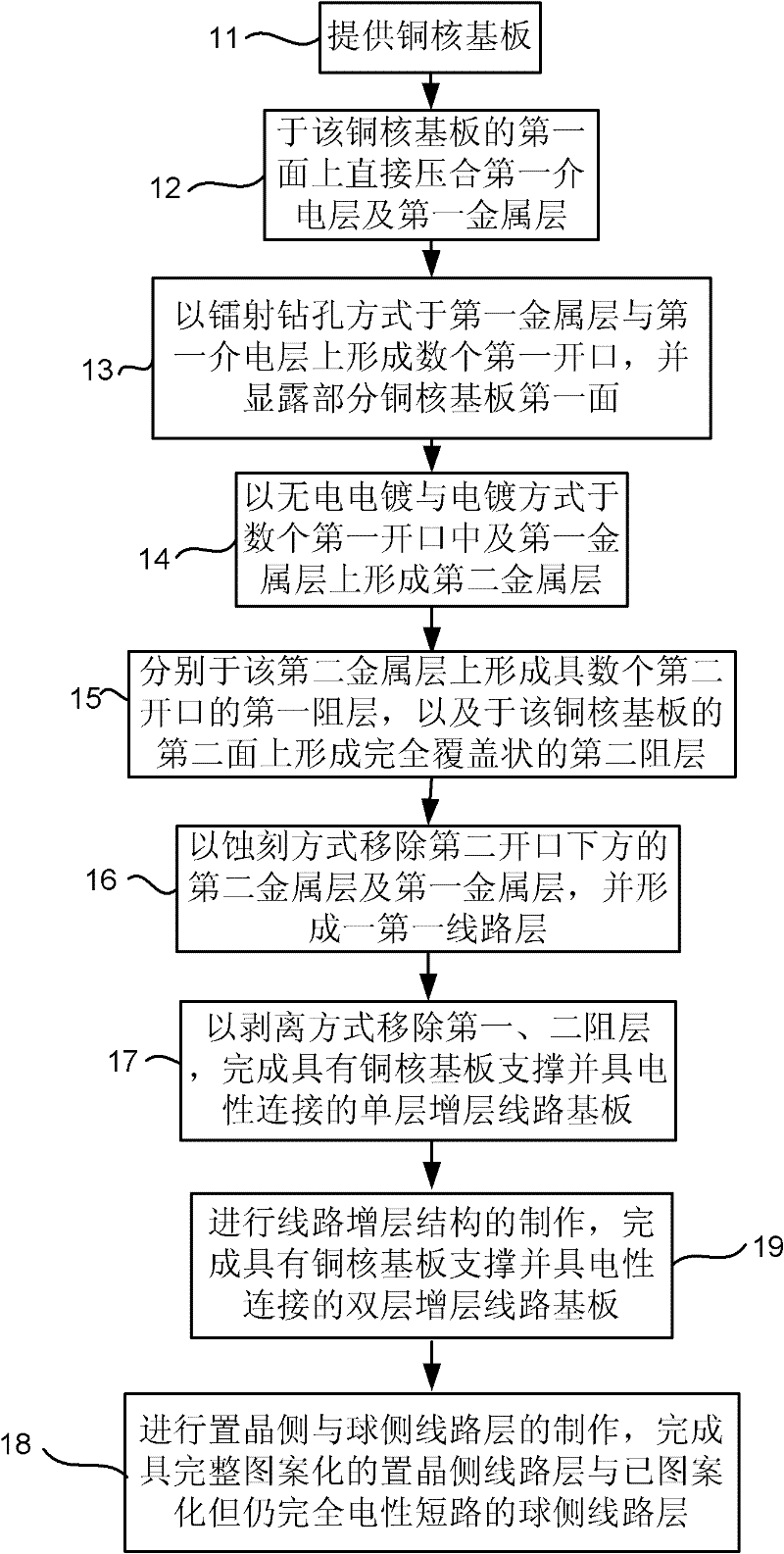

[0094] see figure 1 Shown is a schematic diagram of the production process of the present invention. As shown in the figure: the present invention is a method for manufacturing a copper core layer multilayer packaging substrate, which at least includes the following steps:

[0095] (A) Provide copper core substrate 11: provide a copper core substrate;

[0096] (B) Forming the first dielectric layer and the first metal layer 12: directly pressing a first dielectric layer and a first metal layer on the first surface of the copper core substrate, or first bonding the first dielectric layer After a dielectric layer, the first metal layer is formed;

[0097] (C) Forming several first openings 13: forming several first openings on the first metal layer and the first dielectric layer by laser drilling, and exposing part of the first surface of the copper core substrate, wherein , Several first openings can be formed by opening copper windows (Conformal Mask) first, and then forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com