Tungsten metallization-multilayer alumina black porcelain substrate and preparation method thereof

A multi-layer alumina and metallization technology, which is applied in the field of co-fired ceramics, can solve problems affecting product yield, achieve high flatness, good bonding, and offset mismatching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A first aspect of the present invention provides a method for preparing a tungsten metallization-multilayer alumina black ceramic substrate, comprising the following steps:

[0029] Preparation of laminates

[0030] The preparation of the laminated body in the present invention is basically the same as the conventional laminated body preparation process in the field, that is, the tungsten paste is printed on the green ceramic tape and laminated. Among them, in the embodiment of the present invention, firstly, multiple sheets of alumina green ceramic tapes with a certain thickness in the same batch are selected, and tungsten paste is evenly printed on the front and back sides of one green ceramic tape, and the rest of the green ceramic tapes are not Do the printing process; then stack the green ceramic tapes in sequence, and then stack them, wherein the green ceramic tapes with the tungsten paste evenly printed on the front and back sides are located on the top layer. ...

Embodiment 1

[0037] In the present embodiment, the preparation of tungsten metallization-multilayer alumina black ceramic substrate, the specific steps are as follows:

[0038] Green Porcelain Printing: Select 3 pieces of alumina green porcelain with a thickness of 0.25mm from the same batch, and evenly print tungsten paste on the front and back of one piece of green porcelain, while the other two pieces of green porcelain are not printed;

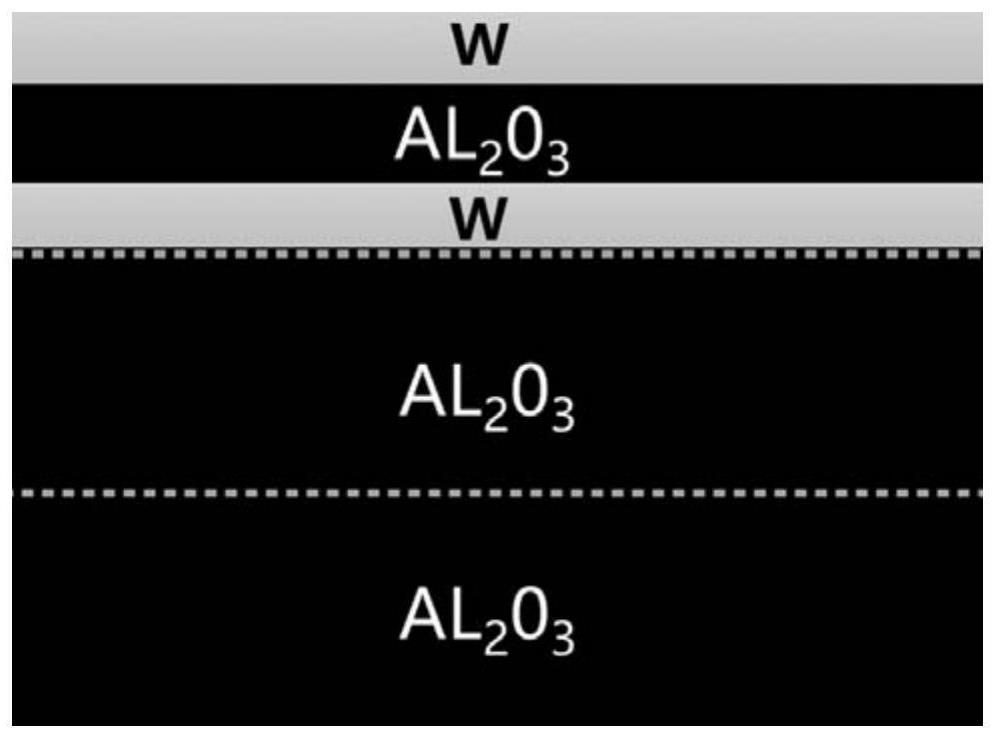

[0039] Green porcelain isostatic pressing: press the printed three pieces of green porcelain figure 1 (The top layer of Al 2 O 3 The front and back sides of the porcelain are printed with tungsten paste) sequentially stacked, and the stacking process conditions are 60 ° C, 2000 psi;

[0040] Raw cut: Cut the laminated green porcelain into 200×200mm squares;

[0041]Co-firing: put the green body into a high-temperature sintering furnace, vacuumize the furnace cavity to a degree of vacuum less than 1Pa at room temperature, and then introduce a mixed g...

Embodiment 2

[0045] In the present embodiment, the preparation of tungsten metallization-multilayer alumina black ceramic substrate, the specific steps are as follows:

[0046] Green Porcelain Printing: Select 3 pieces of alumina green porcelain with a thickness of 0.25mm from the same batch, and evenly print tungsten paste on the front and back of one piece of green porcelain, while the other two pieces of green porcelain are not printed;

[0047] Green porcelain isostatic pressing: press the printed three pieces of green porcelain figure 1 Sequential lamination, lamination process conditions are 60 ° C, 2000 psi;

[0048] Raw cut: Cut the laminated green porcelain into 200×200mm squares;

[0049] Co-firing: put the green body into a high-temperature sintering furnace, vacuumize the furnace cavity to a degree of vacuum less than 1Pa at room temperature, and then introduce a mixed gas of nitrogen and wet hydrogen (nitrogen / wet hydrogen v / v=1:3); 2°C / min to 550°C, hold for 2h; then rise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warpage | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com