Method for reducing pulverization rate of leaf shred bin type feeding machine for preparing tobacco shreds

A silk bin type, silk-making thread technology, applied in the direction of tobacco, tobacco preparation, conveyor, etc., can solve the problem of shredded leaf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

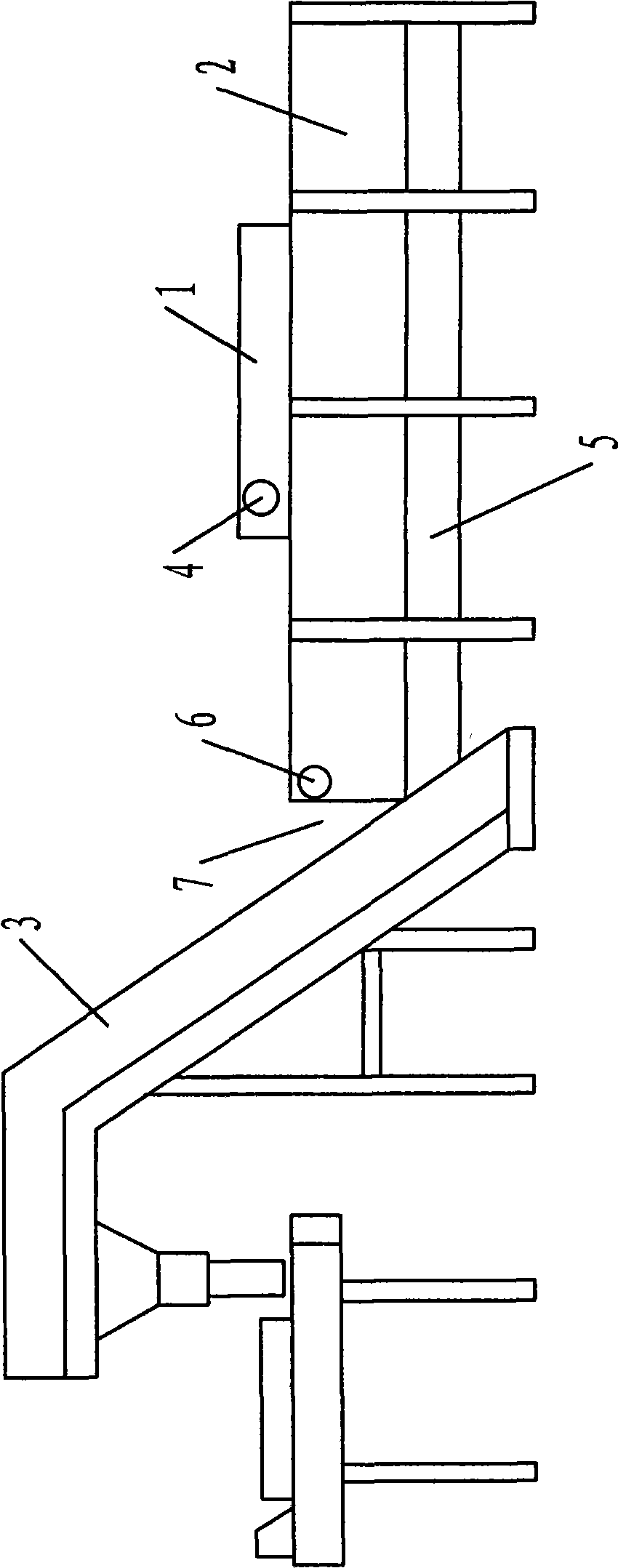

[0020] The present invention controls and adjusts the electrical program and detection devices of the shredded bin feeder in order to reduce the crushing of the shredded bin type feeder and reduce the crushing rate of the shredded shredded bin type feeder for tobacco thread, Specifically include the following steps:

[0021] 1. Control (restrict) the operating conditions of the bottom belt 5 of the tobacco bin feeder. The bottom belt 5 must run on the lifting belt 3 and the plugging photoelectric cell 6 does not detect the shredded tobacco, so as to reduce the amount of shredded tobacco. Extrusion degree in the triangular area 7 at the front of the lifting belt 3 and the storage bin 2;

[0022] 2. Reduce the delay time of the blocking material photoelectric cell 6, from 1 second to 50 milliseconds, so as to reduce the amplitude of the forward rush of the blade silk;

[0023] 3. Reduce the detection distance of the diffuse reflection photoelectric cell 4 at the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com