Method for preparing attapulgite clay catalyst and method for measuring COD by the catalyst

A technology for attapulgite clay and catalyst, which is applied in the field of preparation of attapulgite clay catalyst, can solve problems such as unseen measurement of COD, and achieve the effects of improving development and utilization value, simple preparation method, and shortening measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: the preparation of attapulgite catalyst:

[0024] (1) Purification of attapulgite: Take 100 meshes of original attapulgite and add it into water according to the mass ratio of 1:10 and stir for 24 hours to obtain attapulgite slurry, let it stand naturally, take the upper suspension, filter, dry, and grind to obtain purified attapulgite;

[0025] (2) Acidification treatment: add the purified attapulgite into the mixed acid solution according to the mass ratio of 1:10, boil for 70 minutes under constant stirring, filter and wash until neutral, dry and grind to obtain the acidified attapulgite, that is, the attapulgite catalyst; Wherein, the mixed acid solution with a concentration of 5% by volume is composed of sulfuric acid and phosphoric acid.

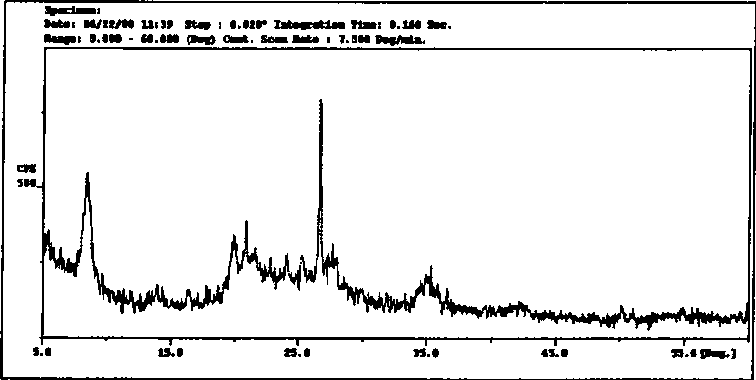

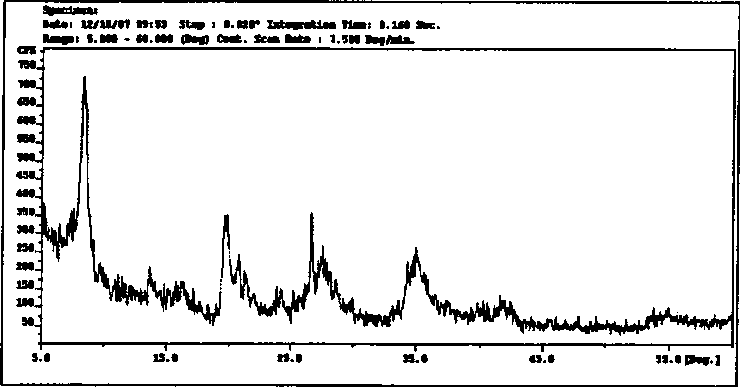

[0026] The XRD pattern of the acidified attapulgite obtained by example 1 is as follows figure 2 As shown, the XRD of the original attapulgite is as follows figure 1 shown by figure 1 , 2 It can be seen that the ...

example 2

[0027] Example 2: the preparation of attapulgite catalyst:

[0028] (1) Purification of attapulgite: Take 150 meshes of original attapulgite and add it into water according to the mass ratio of 1:13 and stir for 36 hours to obtain attapulgite slurry, let it stand naturally, take the upper suspension, filter, dry, and grind to obtain purified attapulgite;

[0029] (2) Acidification treatment, add purified attapulgite into the mixed acid solution according to the mass ratio of 1:13, boil for 80 minutes under constant stirring, filter and wash to neutral after boiling, dry and grind to obtain acidified attapulgite, that is, attapulgite catalyst ; Among them, the mixed acid solution with a concentration of 5% by volume is 5% mixed with sulfuric acid and phosphoric acid.

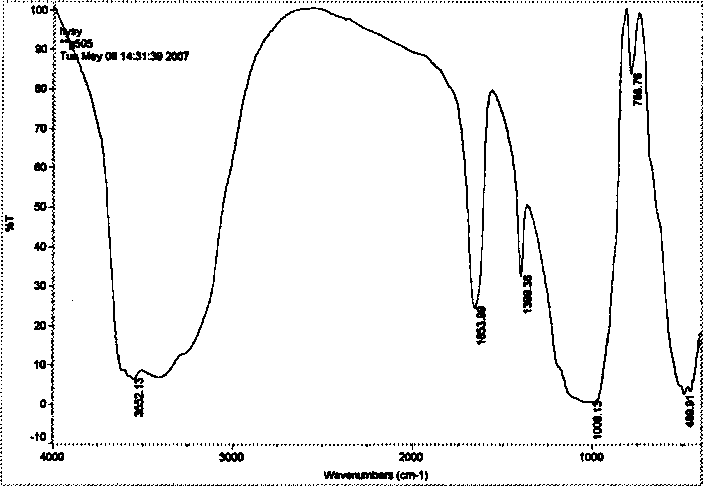

[0030] The IR figure of the acidified attapulgite obtained by example 2 is as follows Figure 4 As shown, the IR of the original attapulgite is as image 3 shown, from image 3 , 4 It can be seen that the cha...

example 3

[0031] Example 3: the preparation of attapulgite catalyst:

[0032] (1) Purification of attapulgite: take 200 mesh of original attapulgite and add it into water according to the mass ratio of 1:15 and stir for 48 hours to obtain attapulgite slurry, let it stand naturally, take the upper suspension, filter, dry, and grind to obtain purified attapulgite;

[0033] (2) Acidification treatment, add purified attapulgite into the mixed acid solution at a mass ratio of 1:15, boil for 90 minutes under constant stirring, filter and wash until neutral, dry and grind to obtain acidified attapulgite, that is, attapulgite catalyst ; Among them, the mixed acid solution with a concentration of 5% by volume is 5% mixed with sulfuric acid and phosphoric acid.

[0034] The SEM figure of the acidified attapulgite obtained by example 3 is as follows Figure 6 As shown, the SEM of the original attapulgite is as Figure 5 shown, from Figure 5 , 6 It can be seen that the crystal shape of the unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com