An electrical heating high light injection mold of isolation energy-saving structure

An injection mold and electrothermal technology, applied in the field of electrothermal high-gloss injection molds, can solve the problems of high energy consumption, unbalanced temperature rise, increase heating power, etc., and achieve the effects of wide adaptability, balanced temperature rise and overcoming large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

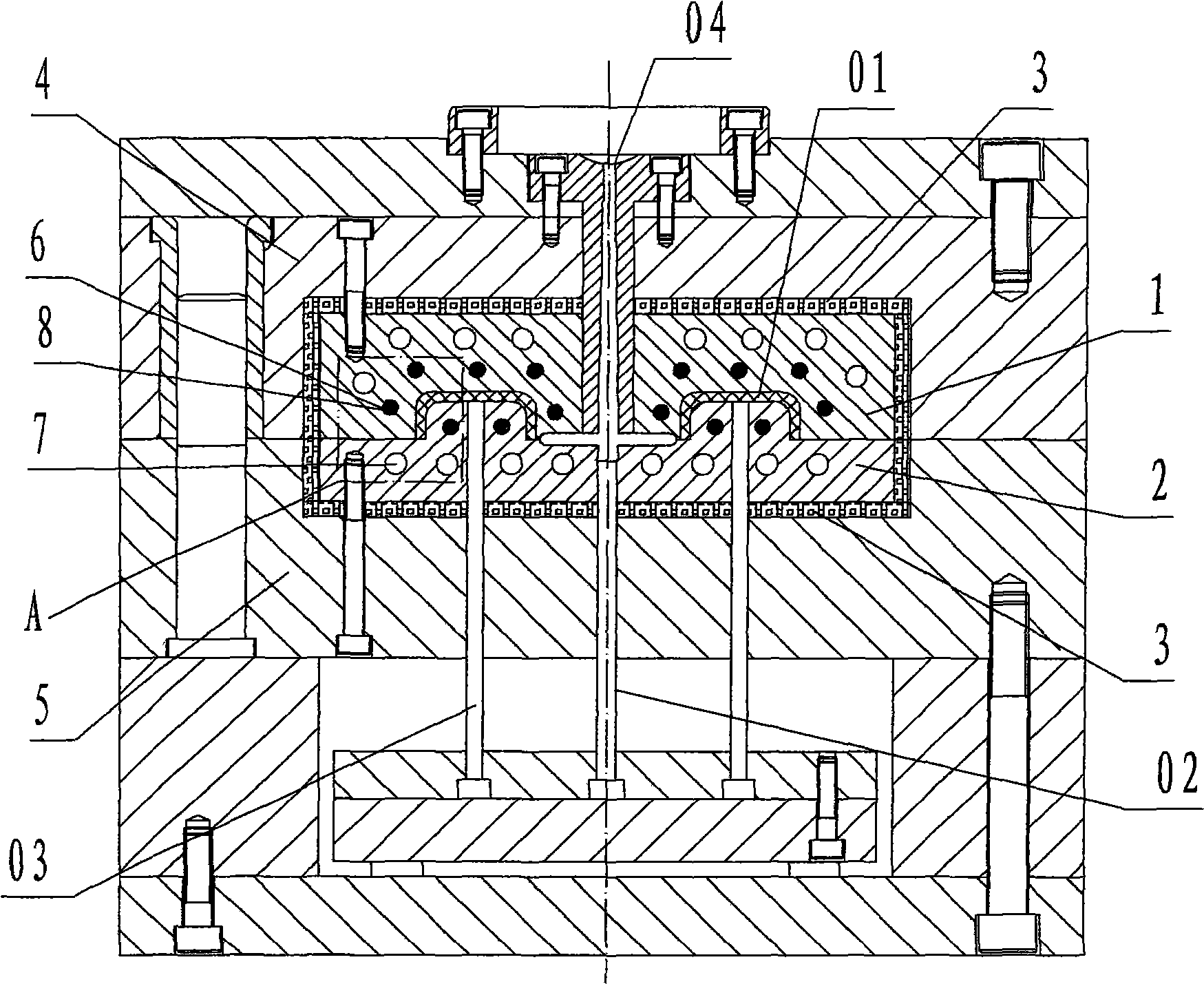

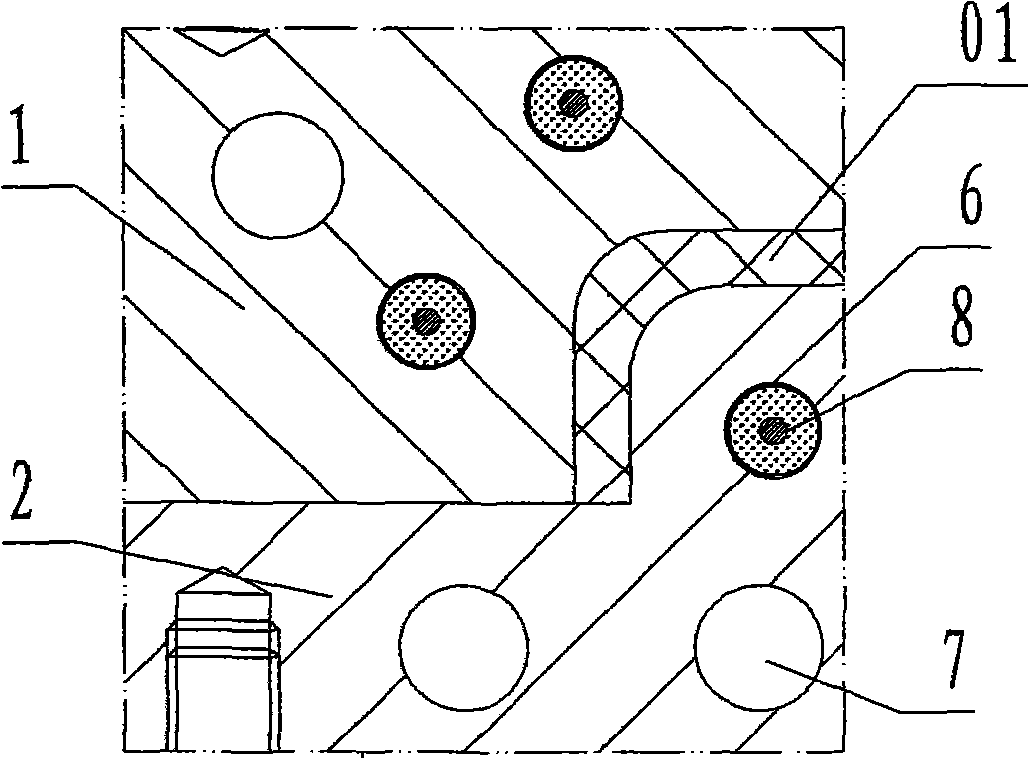

[0021] refer to figure 1 , figure 2 , an electrothermal high-gloss injection mold with a heat-insulating and energy-saving structure of the present invention includes a cavity insert 1, a core insert 2, a heat insulation plate 3, a fixed template 4, a movable template 5, a heating channel 6, and a cooling channel 7, Wherein: the cavity insert 1 is a rectangular plate-shaped steel insert, and its lower end surface is provided with a concave surface matching the outer convex surface of the injection molded product 01, and the upper end surface and four sides are planes. There are several parallel heating channels 6 equidistant from the concave surface in the plate body, and several serial and parallel cooling channels 7 equidistant from the heating channel 6 are arranged on the heating channel 6. The side walls of the plate body The entrance of the heating channel 6 and the interface connected with the cooling channel 7 are provided; the core insert 2 is a rectangular plate-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com