Method for weight-increasing and antimicrobial treatment of silk fiber

A technology of real silk and fibers, applied in the field of weight-enhancing modification and finishing of real silk fibers, can solve the problems of environmental pollution, waste of sericin resources, poor antibacterial properties of silk fibers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

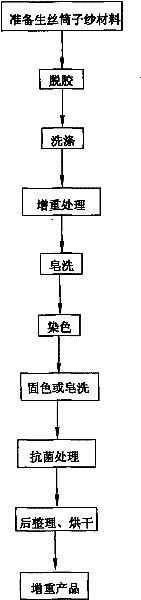

[0013] See attached figure 1 shown. A method for weight gain and antibacterial treatment of real silk fibers, comprising the following steps: preparing raw silk cheese yarn material—degumming treatment with silk refining agent—washing treatment—weight gain treatment—soaping—dyeing—fixing color Or soaping - antibacterial treatment - finishing, drying - weight gain (modified) products.

[0014] In the step of preparing the raw silk package material, silk fiber is used as an example, and 100Kg of pure silk fiber is weighed as the material to be processed.

[0015] In the degumming treatment step, the silk refining agent is used to remove the sericin protein according to the conventional process, and then one wash with hot water at 100°C, one wash with warm water at 70°C, and one wash with cold water at room temperature.

[0016] In the weight-increasing treatment step, the grafting liquid is prepared first: the grafting monomer adopts a derivative of methacrylate, such as methy...

Embodiment 2

[0025] See attached figure 1 shown. A method for weight gain and antibacterial treatment of real silk fibers, the steps of which are the same as in Example 1.

[0026] The steps of preparing raw silk cheese yarn material and degumming are the same as in Example 1.

[0027] In the weight-increasing treatment step, the grafting liquid is prepared first: the grafting monomer adopts a derivative of methacrylate, such as methyl methacrylate, ethyl methacrylate, propyl methacrylate or methacrylic acid One or more mixtures of butyl esters, the addition amount is 66% of the fabric weight; ammonium persulfate is used as the initiator; the nonionic surfactant is flat plus O, and the addition amount is 0.8g / l; dispersion Agent WA, the addition amount is 1g / l; Soft water is used as the solvent, and the bath ratio is 1:15; The pH value of the grafting liquid is adjusted to 3-4 with a mixture of formic acid and acetic acid. The weight-increasing treatment step is carried out in a closed ...

Embodiment 3

[0032] See attached figure 1 shown. A method for weight gain and antibacterial modification of real silk fibers, the steps of which are the same as in Example 1.

[0033] The steps of preparing raw silk cheese yarn material and degumming are the same as in Example 1.

[0034] In the weight-increasing treatment step, the grafting liquid is prepared first: the grafting monomer adopts a derivative of methacrylate, such as methyl methacrylate, ethyl methacrylate, propyl methacrylate or methacrylic acid One or more mixtures of butyl esters, the addition of which is 66% of the fabric weight; and adding degumming wastewater accounting for 10%, 20%, and 30% of the fabric weight respectively; using ammonium persulfate as the initiator; The non-ionic surfactant is Pingping plus O, and the addition amount is 0.8g / l; the dispersant WA, the addition amount is 1g / l; the solvent is soft water, and the bath ratio is 1:15; the grafting is adjusted with a mixture of formic acid and acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com