Combined type door leaf

A combined door leaf and matching technology, which is applied in the direction of door leaf, decorative art, and the technology used to produce decorative surface effects, etc., can solve the problems of difficult processing technology, difficult production and processing, and increased input of manpower and material resources, etc., to achieve The effect of shortening the production cycle, easy processing and manufacturing, and enhancing the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

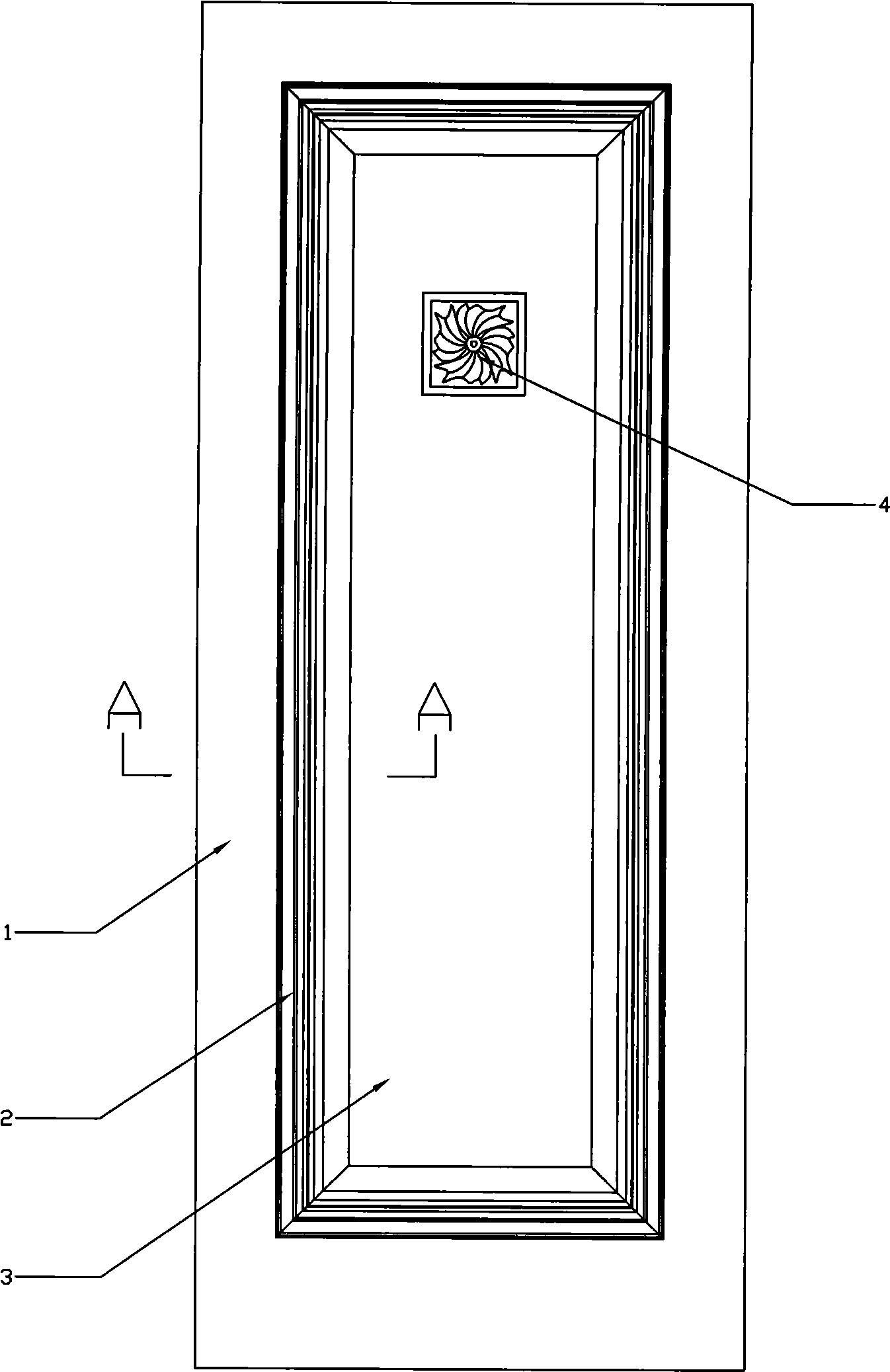

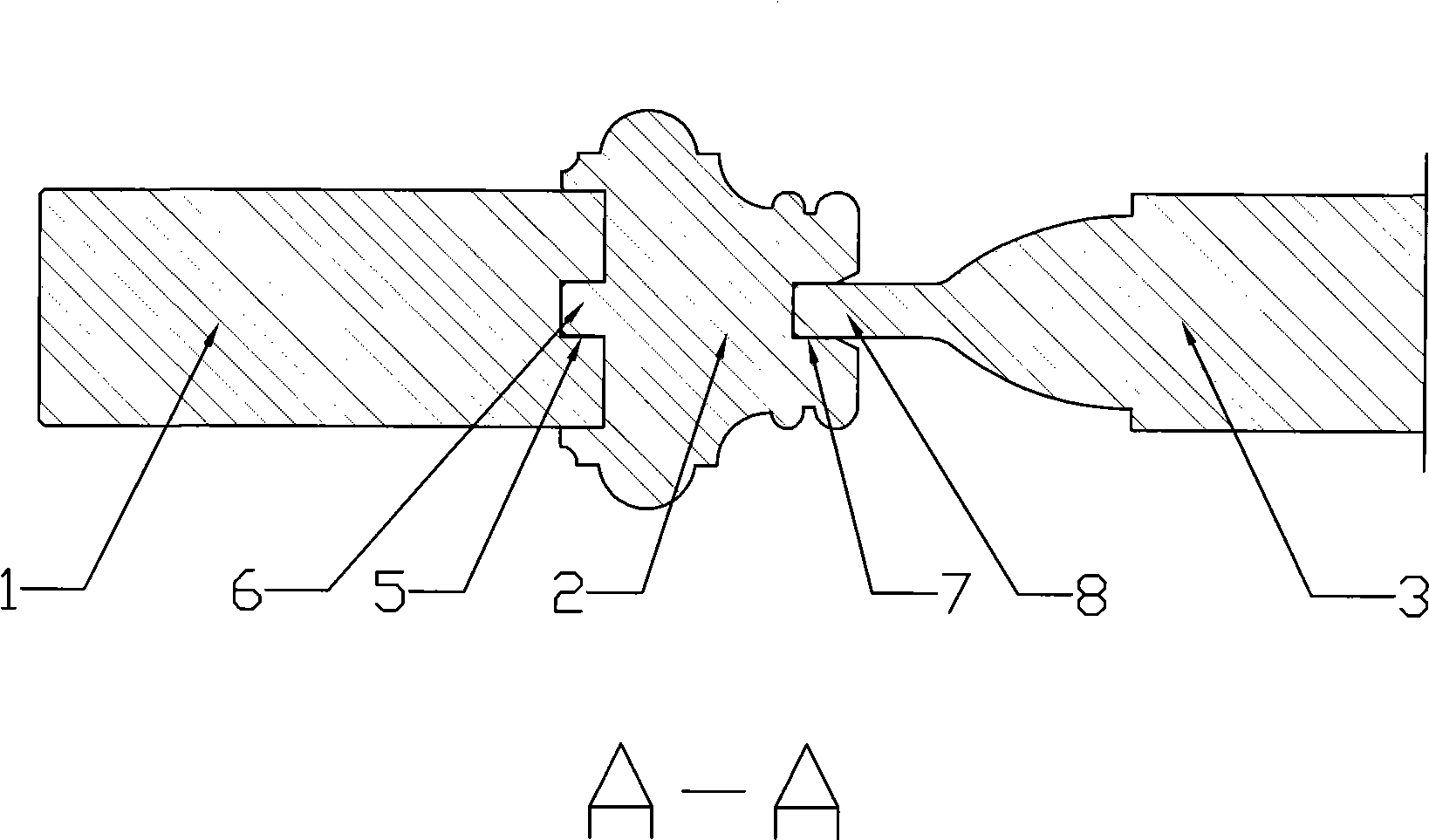

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a side frame 1, a decorative strip 2, and a pool plate 3. The inner end surface of the side frame 1 is provided with a groove I5, and the two ends of the decorative strip 2 are respectively provided with a convex edge I6 and a groove II7. The side end of the pool plate 3 is provided with a convex edge II8, and the convex edge I6 is matched with and bonded to the groove I5, and the decorative strip 2 covers the matching end of the side frame 1 inside, and the "outer jacket" fits , the convex edge II8 is matched and bonded with the groove II7 to form the whole door leaf. Due to the method of cooperating and bonding, the structure of the wooden door is reasonable and nail marks are avoided. The decorative strip 2 is a single whole, It can be processed and formed at one time, which greatly reduces the workload, saves manpower and material resources, and improves production efficiency. The convex edge I6...

Embodiment 2

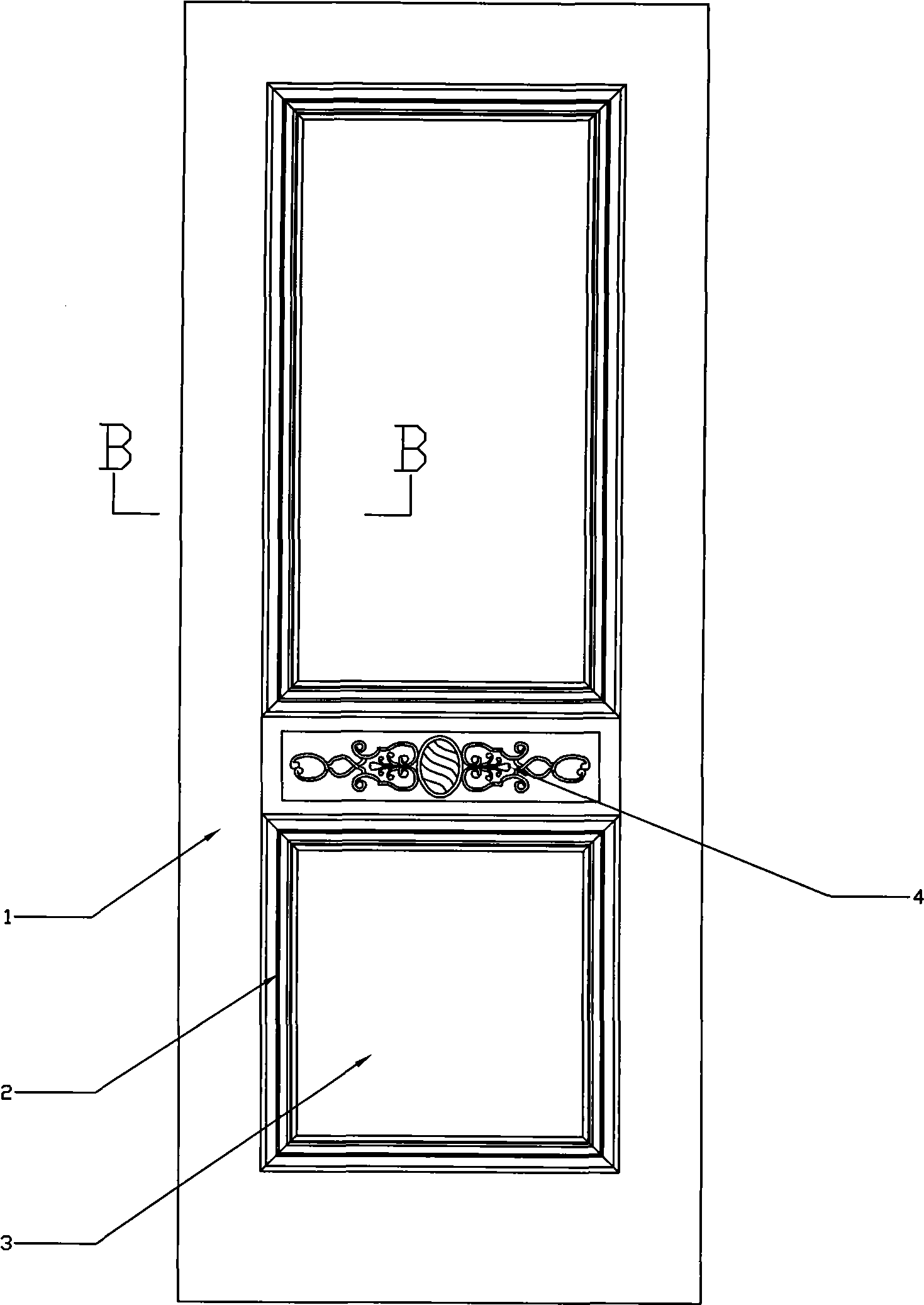

[0020] Such as image 3 , Figure 4 As shown, the groove I5 of the side frame 1 of a combined door leaf of this embodiment is matched with and bonded to the convex edge I6 of the decorative strip 2, and the convex edge I6 is inserted into the groove I5. That is, "inlaid" type fit, other features of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com