Method for automatically closing coal mine explosion-proof cover (door) after opening by explosion shock wave

An explosion shock wave, automatic closing technology, applied in mining installations, mining equipment, earthwork drilling and other directions, can solve problems such as hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

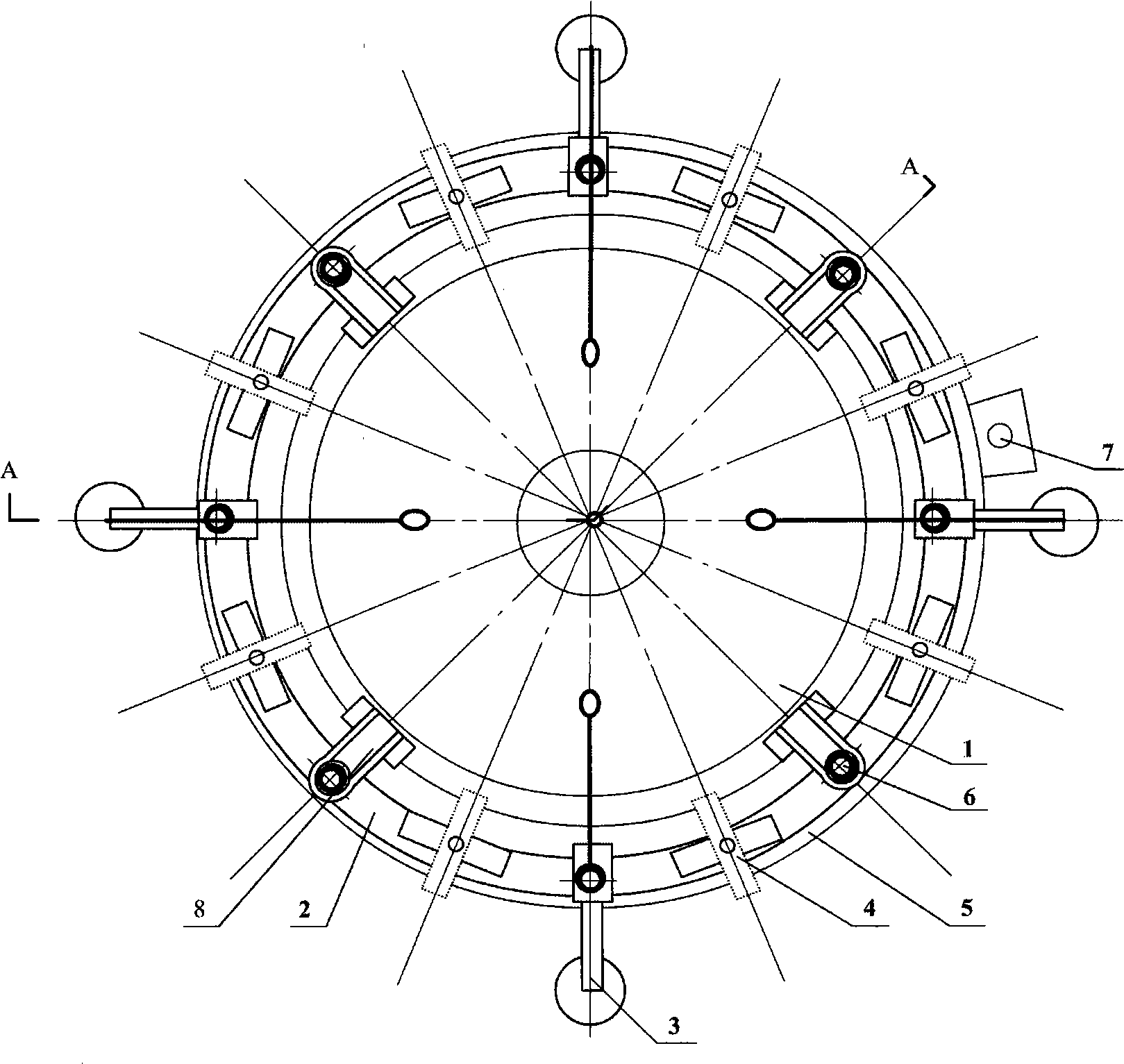

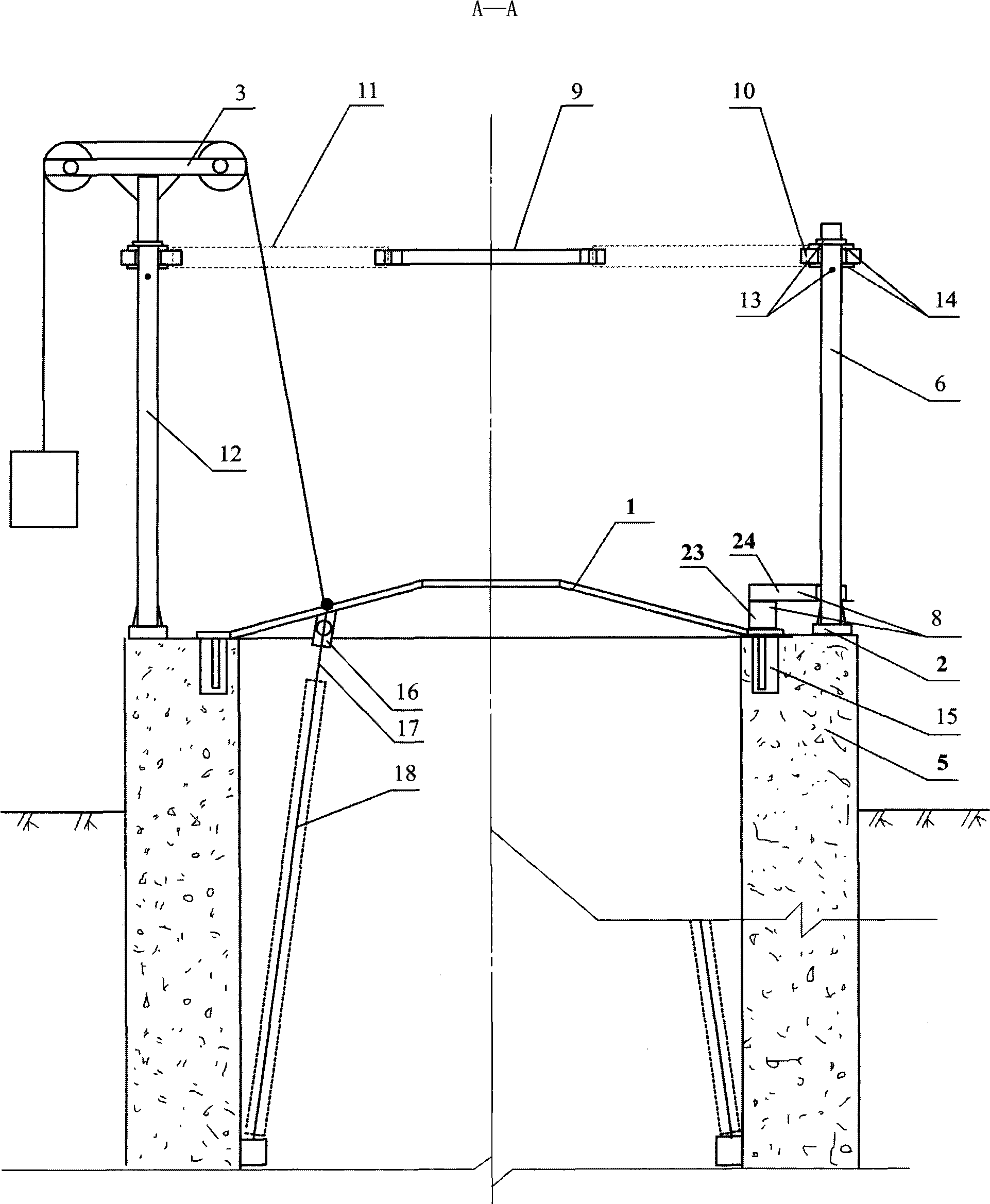

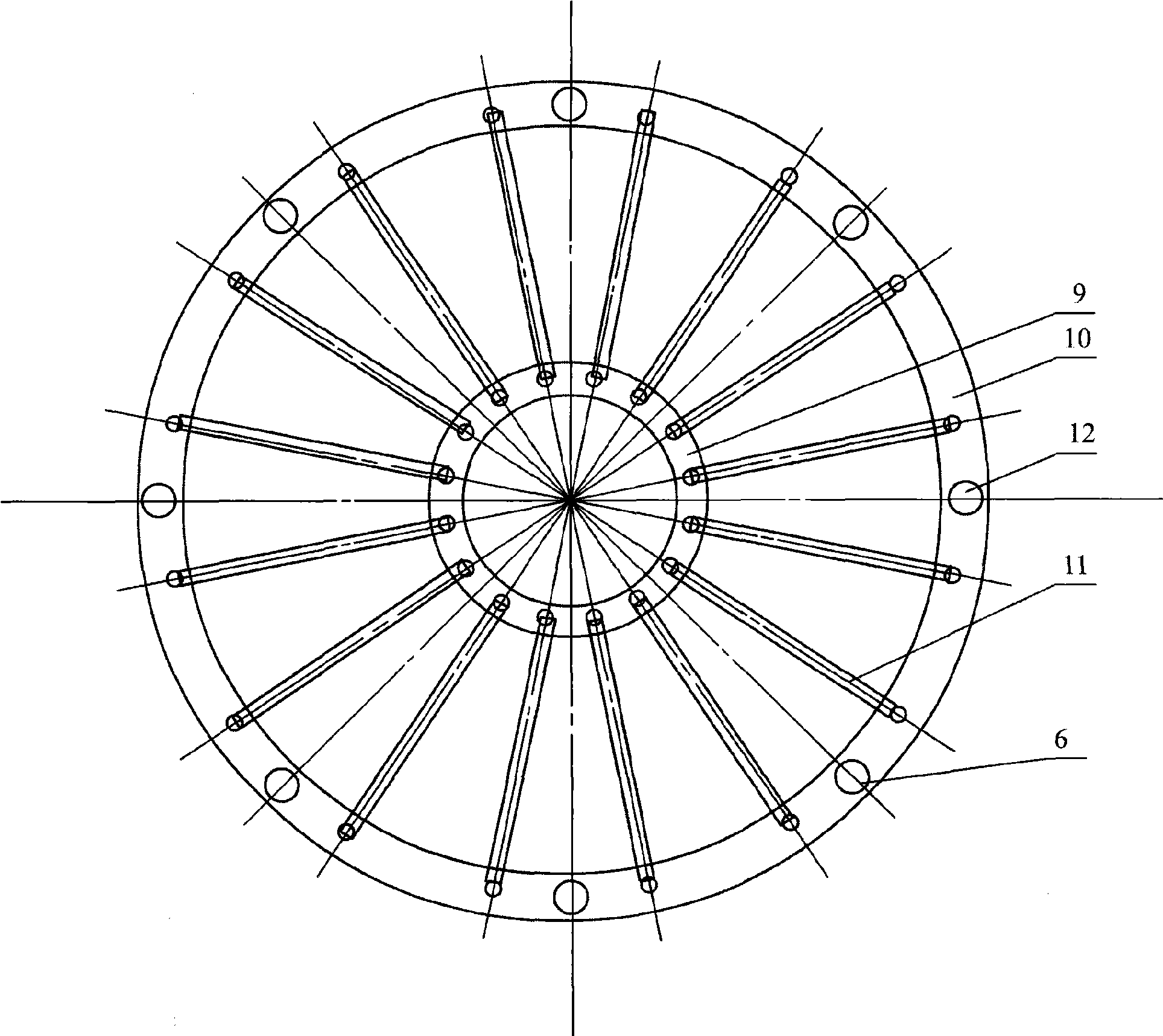

[0033] In embodiment one: the application of the method proposed by the present invention in the air shaft is a vertical shaft, including: the existing air shaft explosion-proof cover (1) and sealing groove (15), counterweight device (3), anti-wind device (4) and other auxiliary facilities basically do not change the structure and function, and increase the guide device (8) of the explosion-proof cover (8), the limit device of the explosion-proof cover (1) and the automatic closing device of the explosion-proof cover (1), which is characterized in that: the explosion-proof cover (1) The limit device installs four guide rods (6) of the explosion-proof cover (1) and four groups of counterweight device vertical rods (12) on a horizontal plane at the top; the guide device (8) of the explosion-proof cover (1) is installed on the explosion-proof cover (1) around, so that the opening and closing of the explosion-proof cover (1) can only move vertically along the center line of the wel...

Embodiment 2

[0038] Embodiment two: the method that the present invention proposes is the application in the inclined shaft of air shaft, and the rotation shaft (19) of this inclined shaft explosion-proof door (20) is at the top of explosion-proof door (20), comprises: existing air shaft explosion-proof door (20) and counterweight device (3), anti-wind device (4) and other ancillary facilities basically do not change the structure and function, increase the automatic closing device of the explosion-proof door (20), it is characterized in that: because the explosion-proof door (20) has guiding device and limit device, so do not increase the guide device and limit device when using the explosion-proof door (20); two sets of automatic closing devices for the explosion-proof door (20) are installed in total; the automatic closing device for the explosion-proof door (20), tension spring The snare end is directly installed on the shaft bottom plate (21) inside the explosion-proof door (20), and t...

Embodiment 3

[0040] In embodiment three: the method that the present invention proposes is the application in the inclined shaft, and the rotating shaft (19) of this inclined shaft explosion-proof door (20) is on the both sides of shaft, including: existing air shaft explosion-proof door (20 ) and ancillary facilities basically do not change the structure and function, and increase the automatic closing device of the explosion-proof door (20). Guide device and limit device; two sets of automatic closing devices for explosion-proof doors (20) are installed on each door, and four sets are installed crosswise in total; automatic closing devices for explosion-proof doors, the trap end and the edge of the explosion-proof door (20) Directly connected, the tension spring end is directly installed on the inner well wall (22) of the explosion-proof door (20), which only works when the explosion-proof door (20) is opened by the explosion shock wave, and does not affect the explosion-proof door (20) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com