Pressure power generating device and method thereof

A technology of pressure power generation and pressure device, which can be used in electromechanical devices, wind power generation, wind turbines, etc., and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

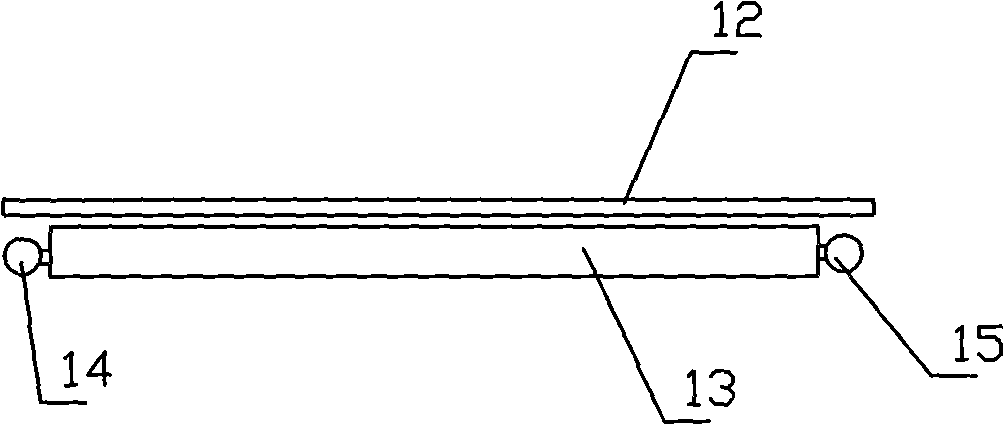

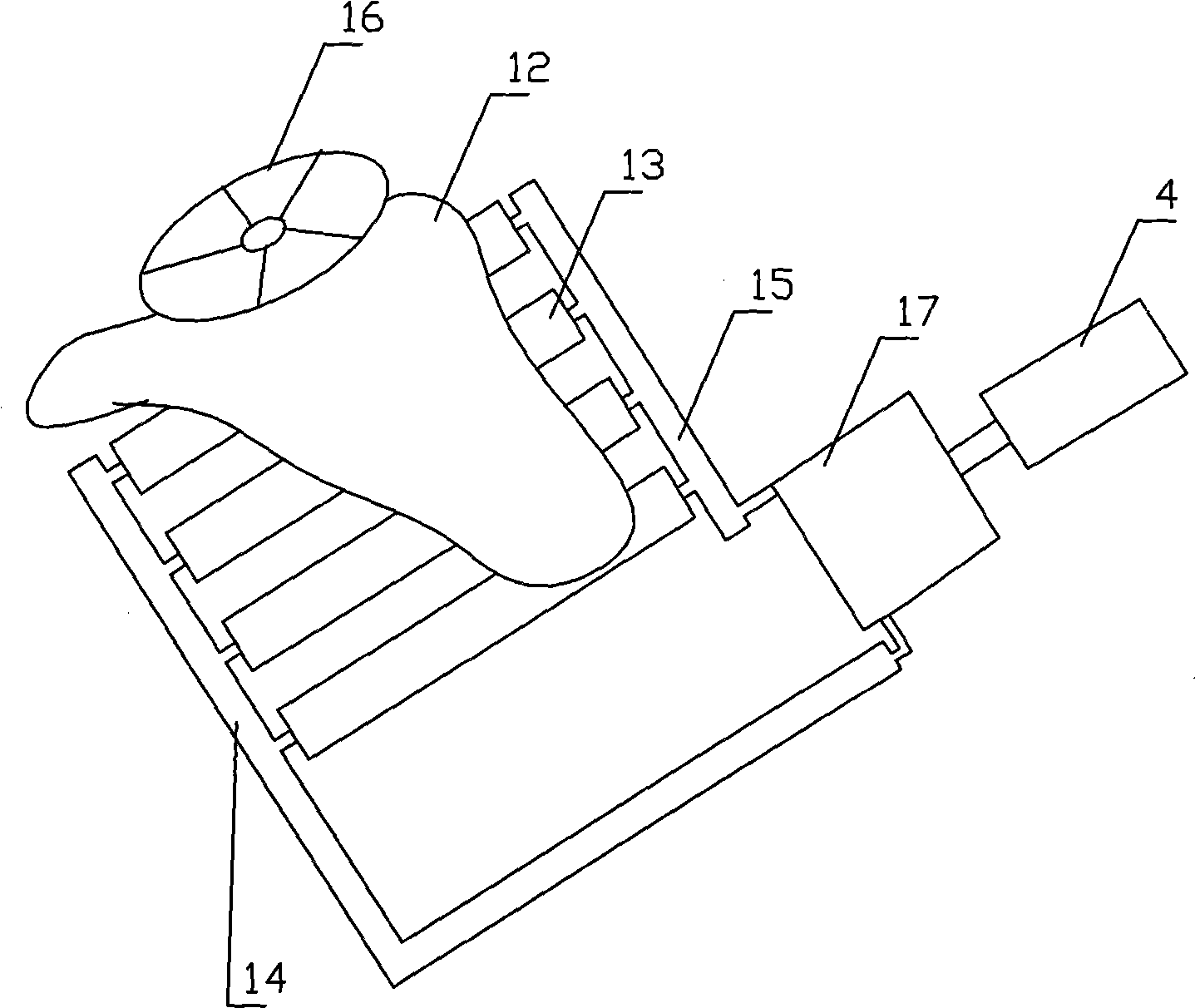

[0022] Embodiment 1: as figure 1 figure 2 As shown, the pressure generating device includes a mechanical energy collector, a hydraulic turbine 17, and a generator 4. The mechanical energy collector is composed of a deformable plastic surface layer 12 and a plurality of tubular pressure devices 13 under the surface layer. Each tubular pressure device 13 Placed parallel to each other, the tubular presses 13 are filled with liquid and made of elastic materials. The head end of each tubular pressor communicates with the low-pressure pipe 14, the tail end of each tubular pressor communicates with the high-pressure pipe 15, and the high-pressure pipe communicates with the hydraulic turbine 17. The liquid inlet is communicated, the low-pressure pipe is communicated with the liquid outlet of the liquid turbine, and the output rotating shaft of the liquid turbine 17 is connected with the rotating shaft of the generator.

[0023] When the wheel 16 of the automobile passes through the ...

Embodiment 2

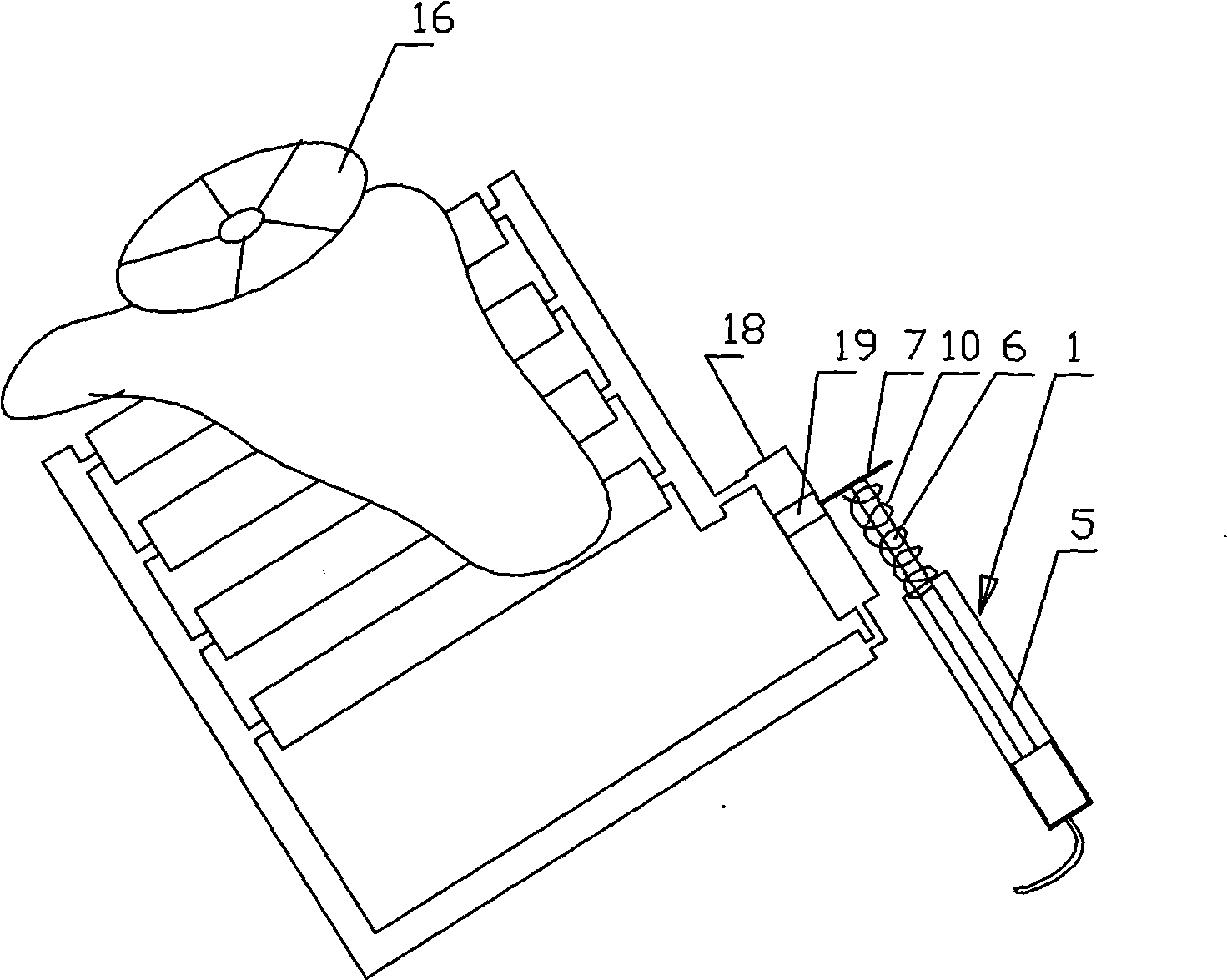

[0024] Embodiment 2: as image 3 , Figure 4 As shown, the pressure power generation device includes a mechanical energy collector, a gas pump device 1 for converting mechanical energy into gas internal energy, a storage tank 2 for storing high-pressure gas, a gas turbine 3 and a generator 4 . The mechanical energy collector is composed of a deformable plastic surface layer and a plurality of tubular pressure devices under the surface layer. The tubular pressure devices are placed parallel to each other. The tubular pressure devices are filled with liquid and made of elastic materials. The head end of each tubular pressure device It communicates with the low-pressure pipe, the tail end of each tubular pressure device communicates with the high-pressure pipe, the high-pressure pipe communicates with the liquid inlet of the piston pump 18, and the low-pressure pipe communicates with the liquid outlet of the piston pump. The air pump device is a conventional traditional air pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com