Weighing control device of hopper scale and method thereof

A technology of control device and hopper scale, which is applied in the direction of measuring device, weighing, automatic feeding/discharging weighing equipment, etc., can solve problems such as difficult to find in operation, inaccurate measurement of hopper scale, measurement loss, etc., and achieve easy Maintenance, long service life and high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

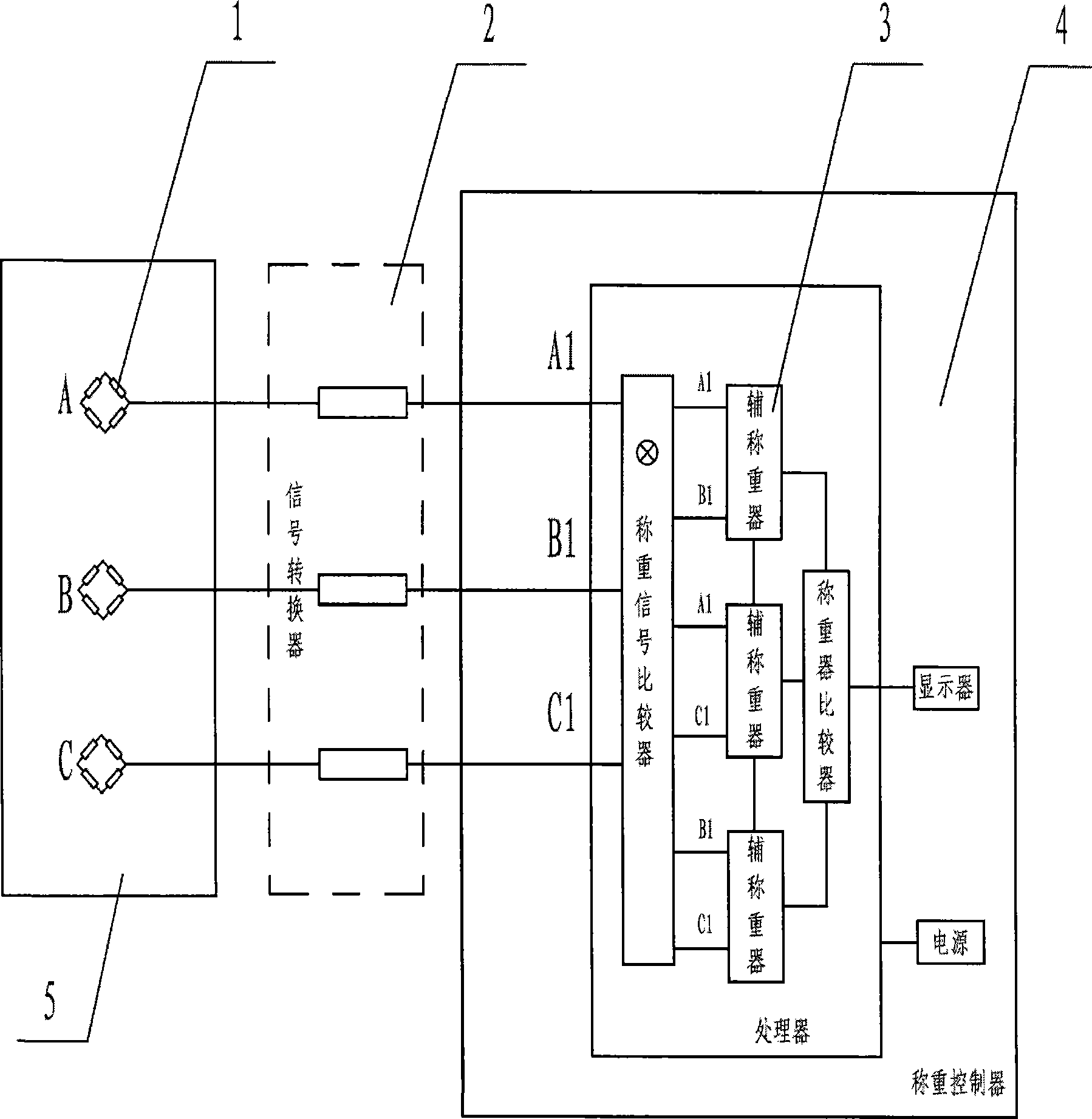

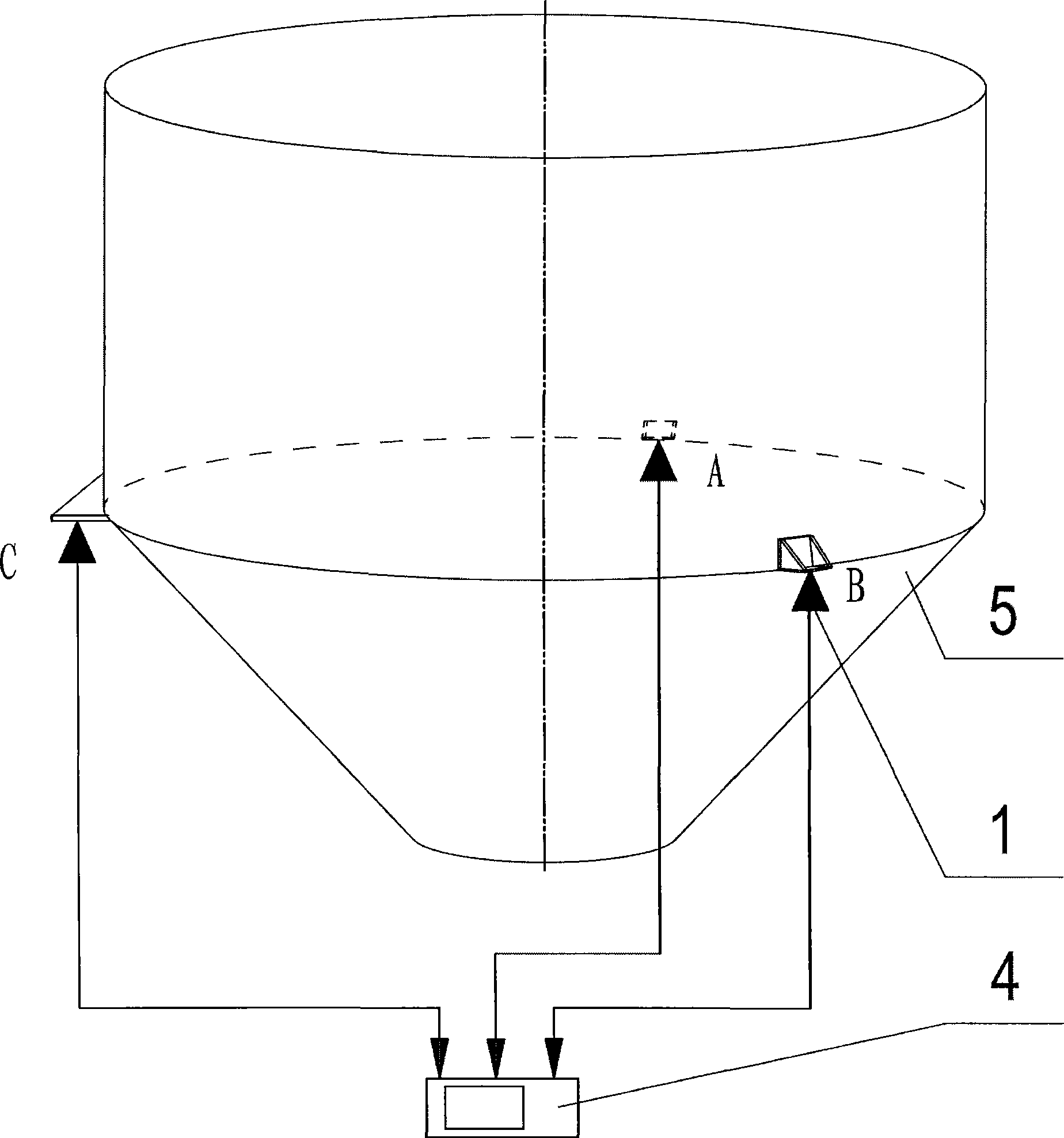

[0029] Embodiment one, figure 1 and figure 2 As shown, the weighing control device of the hopper scale is mainly composed of three load cells 1 A, B, and C, a fully suspended weighing hopper 5 supported by three load cells 1 , and a load controller 4 . When the load cell 1 is an analog signal sensor, the load cell 1 is connected with a signal converter 2, such as figure 1 Shown; When the load cell 1 is a digital signal sensor, the signal converter 2 is not required. The weighing controller 4 mainly includes a processor, a memory, a display and a power supply, wherein the signal converter 2 is a 24-bit analog-to-digital conversion circuit AD7710, the processor is a 32-bit CPU integrated circuit S3C44BOX, the memory is an integrated circuit 39VF160, and the display is a 640× 320 dot matrix, the power supply is 220V AC. The processor includes a weighing signal comparator, three auxiliary weighing devices 3 connected to it, and a weighing device comparator connected between th...

Embodiment 2

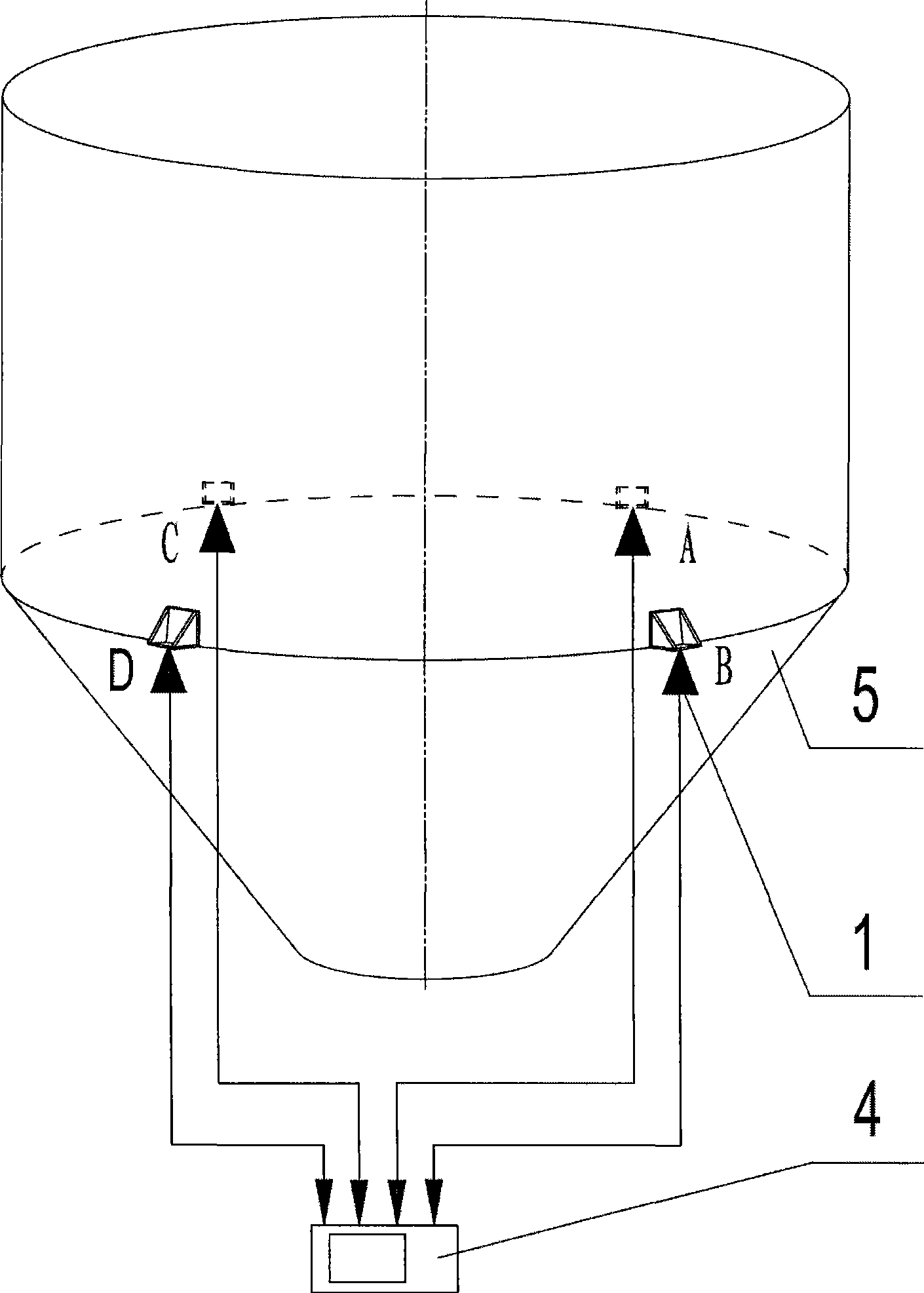

[0038] Embodiment two, image 3 As shown, the number of load cells 1 is four, A, B, C, and D, and the four load cells 1 of A, B, C, and D are evenly arranged outside the weighing hopper 5, and are used as sensors for the fulcrum when forming a lever. The number of 1 is two, and the other two sensors 1 are used as force application points, and other aspects are basically the same as the previous embodiment, and the description is omitted.

[0039] Figure 5 As shown, the weighing control signal comparison program flow of the four load cells 1:

[0040] a. Whether the comparison difference between the two auxiliary weighing devices 3 is within the set range

[0041] b. Yes, it shows that the fully suspended weighing hopper 5 combined with four load cells 1 is the main weighing weight of the structure;

[0042] c. No, the weighing signal comparator compares the weighing signals of the four weighing sensors 1 of A, B, C, and D, and whether the difference is within the set range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com