Feedback control method for calcination process in rotary kiln

A feedback control and rotary kiln technology, which is applied in the direction of electrical program control, controller with specific characteristics, electric controller, etc., can solve problems such as inability to measure online, and achieve the effects of reducing control costs, qualified product quality, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

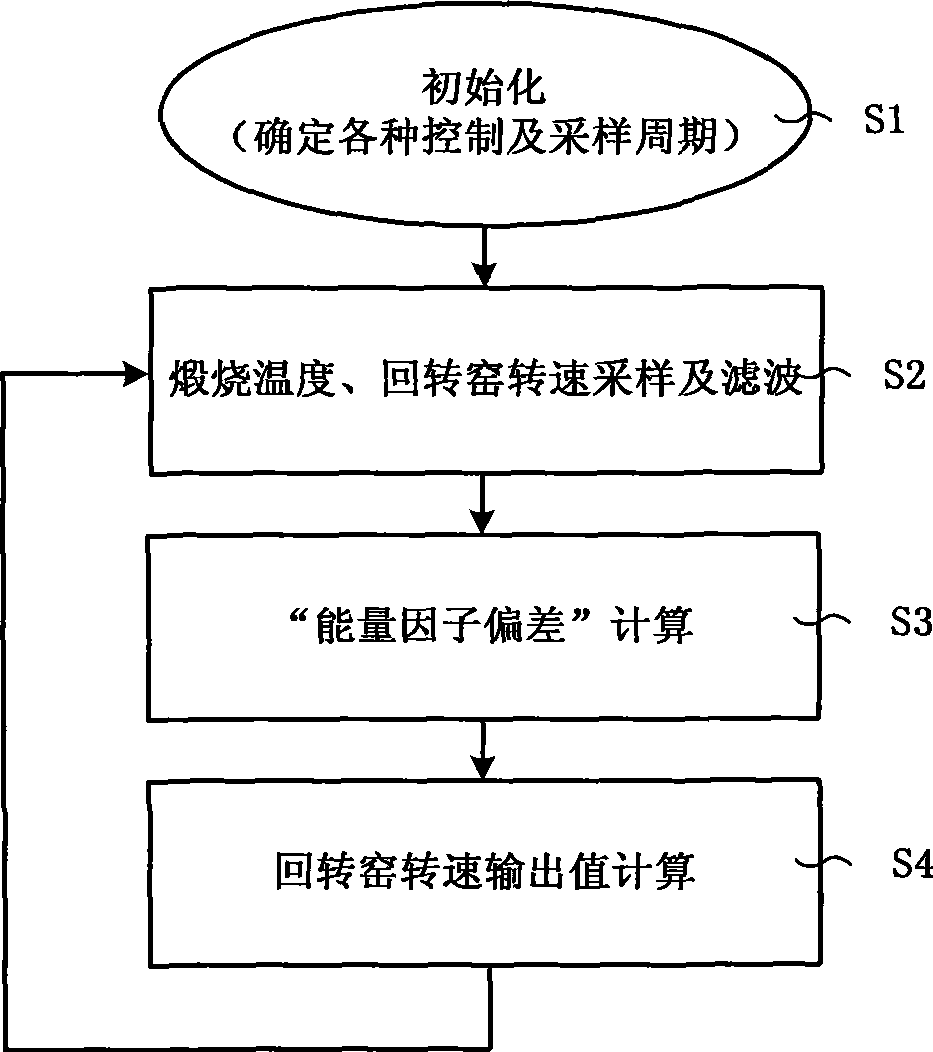

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

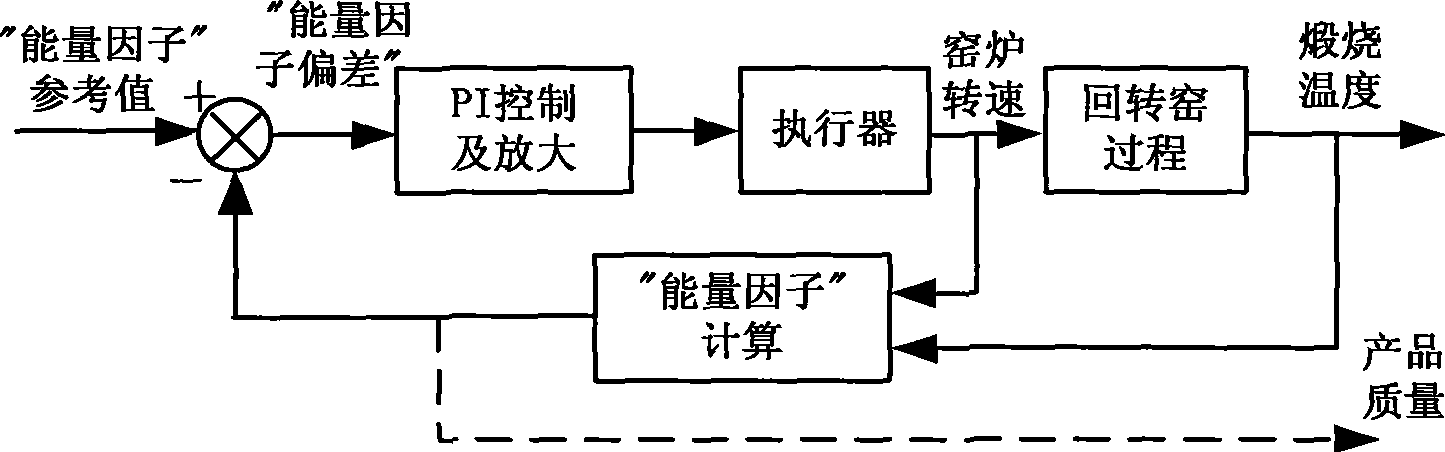

[0023] The control method proposed by the present invention takes the stability of the calcined product quality of the rotary kiln as the control target.

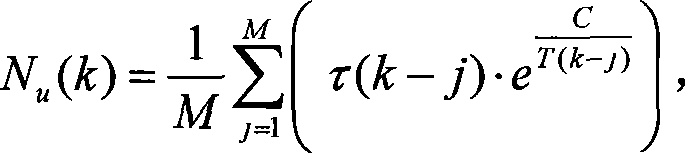

[0024] According to thermostatistics, the energy obtained by the calcination reaction is proportional to the calcination temperature T; at a certain temperature, the average expected time t required for the reaction to occur satisfies the relationship (1):

[0025] t = a · e C T - - - ( 1 )

[0026] Among them, a and C are constants.

[0027] For each type of powder, given the quality and output requirements, the optimum combination of calcination temperature and calcination time can be determined thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com