Magnetic straight-moving driving rotation mechanism

A technology of magnetic force and linear motion, applied in the direction of electromechanical devices, electric components, electromechanical transmission devices, etc., can solve the problems of complex manufacturing, high cost, misuse of energy, etc. of the crankshaft, and achieve the effect of simple process, low cost and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

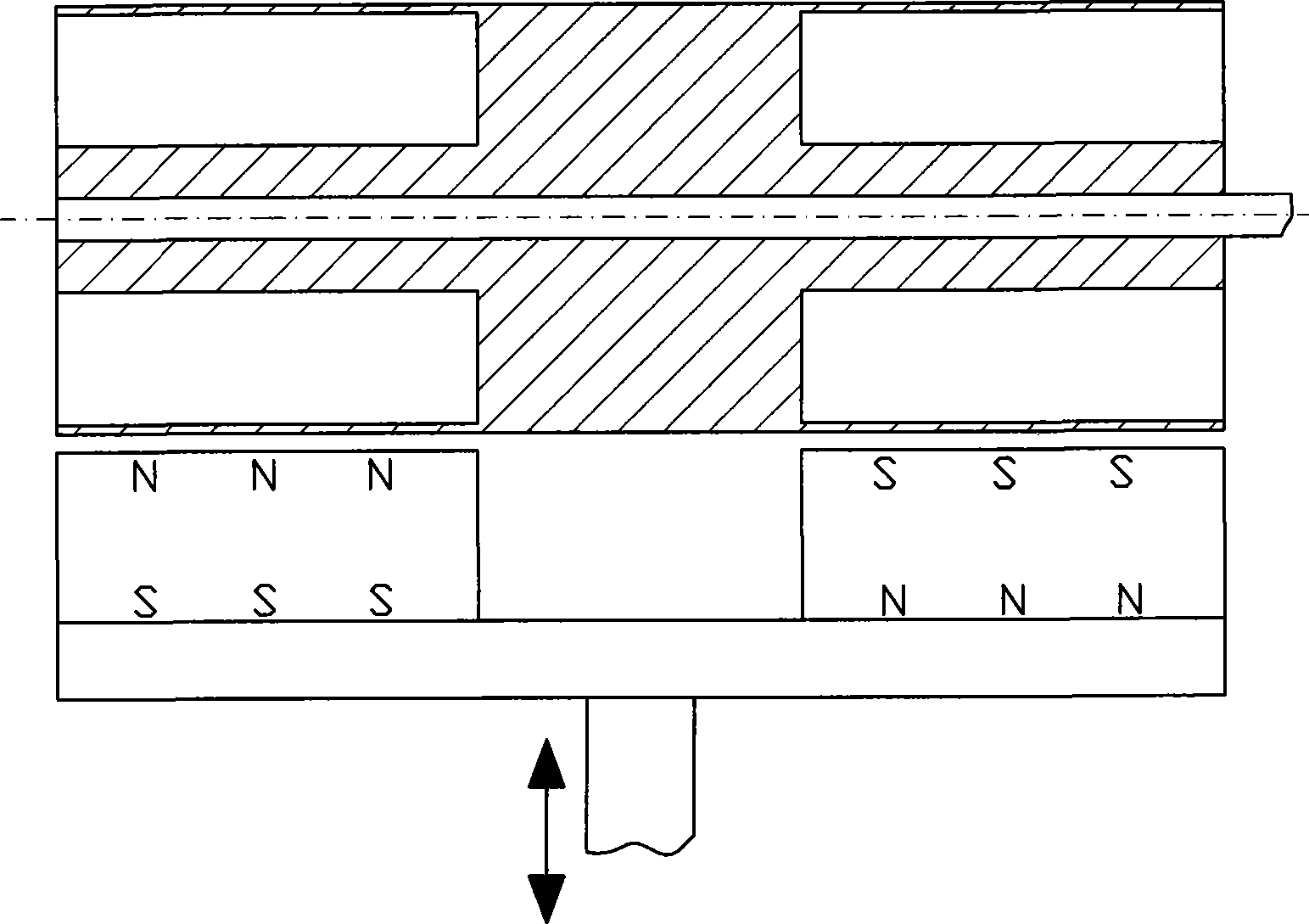

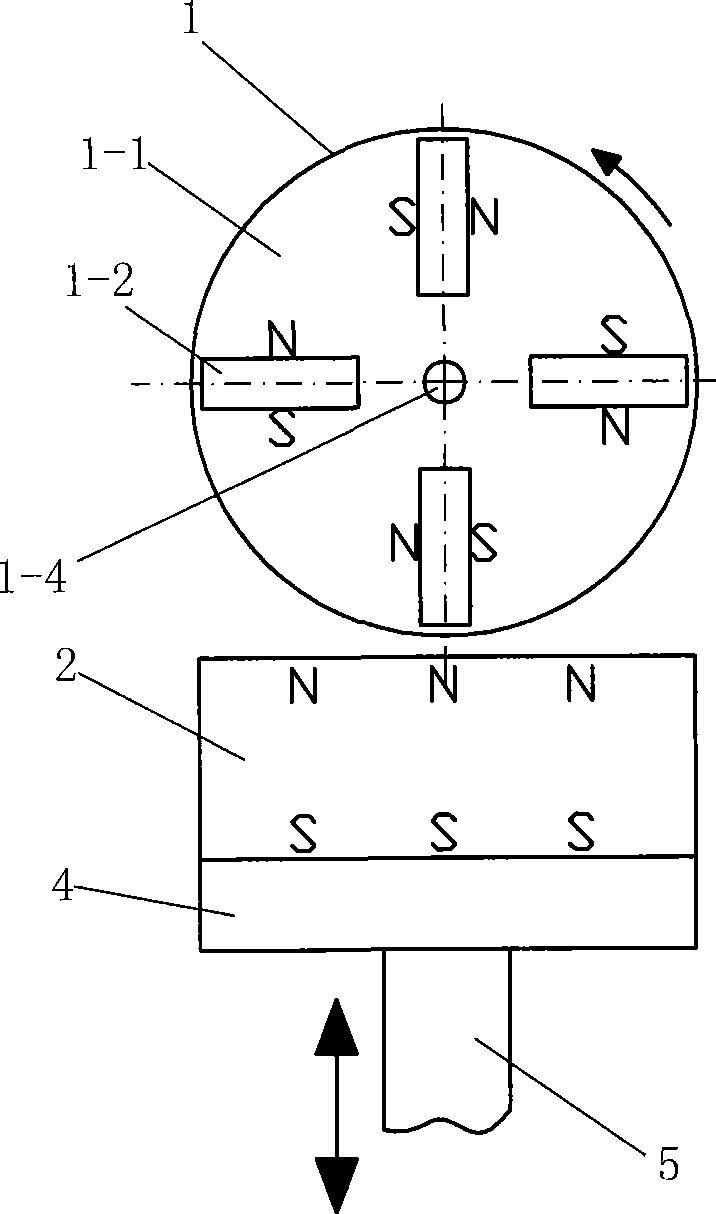

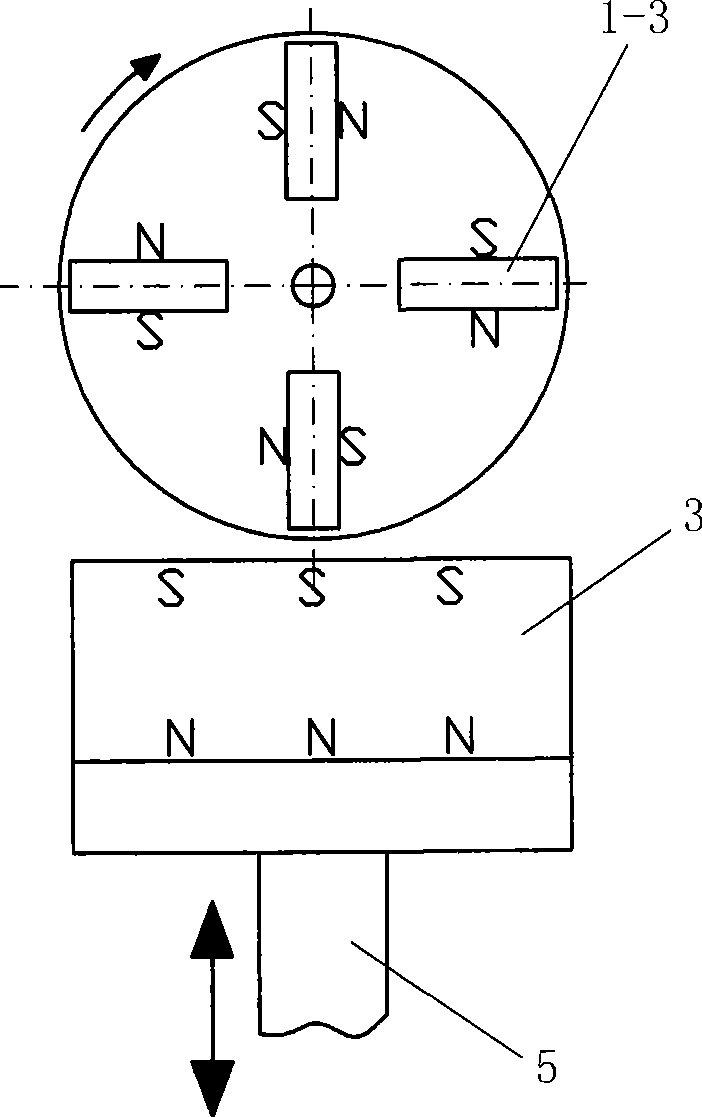

[0022] Embodiment one: if Figure 1 to Figure 3 Show. The magnetic wheel 1 is composed of several permanent magnetic plates 1-2, several permanent magnetic plates 1-3, and a non-magnetic cylinder 1-1 fixed on the rotating shaft 1-4. The permanent magnetic plates 1-2, permanent magnetic plates 1-3 are magnetized along the tangential direction (thickness direction), and the polarity of all permanent magnet plates 1-2 is clockwise (from figure 2 Look), the polarity order of all permanent magnet plates 1-3 is clockwise (from image 3 Look), the neutral plane of the permanent magnet plate 1-2 and the permanent magnet plate 1-3 passes the axis of the rotating shaft 1-4, and the rotating shaft 1-4 is installed on the frame (not drawing in the figure) with a bearing (not shown in the figure) On; the permanent magnet 2 and the permanent magnet 3 magnetized vertically are placed under the magnetic wheel 1, and the polarity direction on the permanent magnet 2 is opposite to that on the...

Embodiment 2

[0023] Embodiment two: if Figure 4 Show. A permanent magnet 7 magnetized vertically is placed below the magnetic wheel 6. The magnetic wheel 6 is the axial half of the magnetic wheel 1 in the first embodiment. The connecting rod 5 is fixed at the center of the bottom surface of the permanent magnet 7, and the connecting rod 5 is in addition One end is connected with a linear motion part (not shown in the figure).

Embodiment 3

[0024] Embodiment three: as Figure 5 Show. The two magnetic wheels 6 described in Embodiment 2 are placed on the upper and lower sides of the vertically magnetized permanent magnet 7, and the permanent magnet 7 is connected with a linear motion member (not shown) by a coupling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com