Preparation method of novel sole and product thereof

A new type of molding technology, applied in the direction of shoe soles, footwear, devices for coating liquid on the surface, etc., can solve the problems of harming the human body, high cost, cumbersome steps, etc., and achieve easy large-scale production, convenient operation, and comfortable feet Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

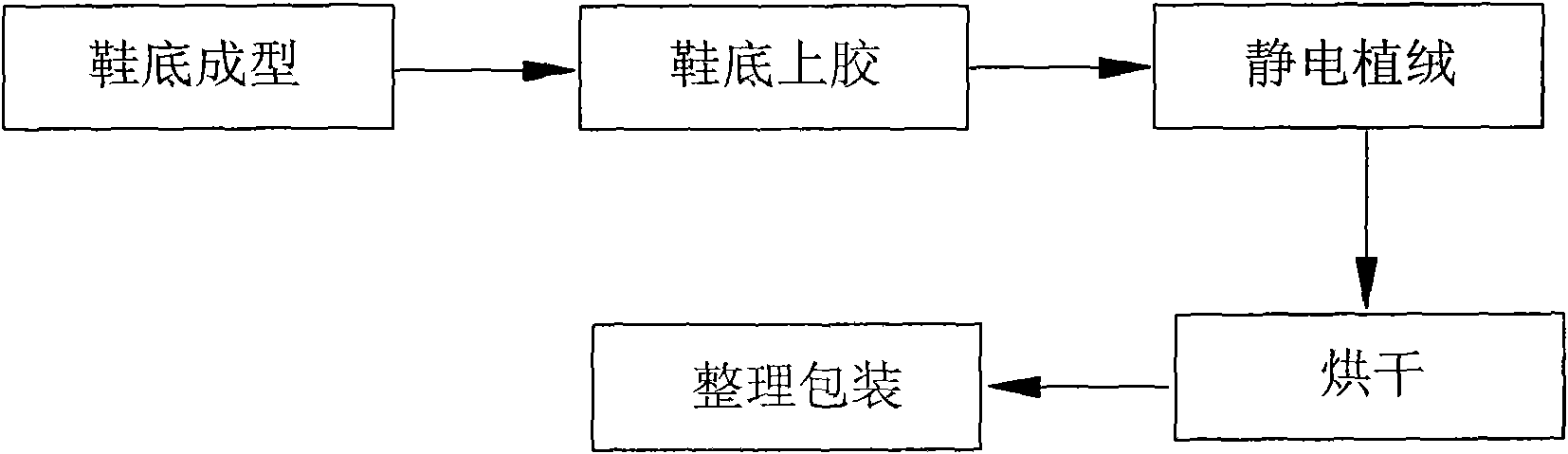

[0042] Embodiment 1: refer to figure 1 , present embodiment provides a kind of novel sole preparation method, it comprises the following steps:

[0043] (1) Sole molding: After melting the plastic, put it into the sole molding machine, and mold it to make the sole base material;

[0044] (2) Sole gluing: Put the sole base material into the gluing machine, apply the adhesive on the surface of the sole base material through the gluing machine, and after more than two treatments from thin to thick, the thickness is 0.06 ~0.16mm glue layer;

[0045] (3) Electrostatic flocking: Put the glued sole base material into the electrostatic flocking room for electrostatic flocking;

[0046] (4) Drying: Put the flocked sole base material into an oven with a temperature of 60-120°C to bake, take it out after drying, cool it, and then brush it with a brush roller to get the finished product;

[0047] (5) Arranging and packaging: Arranging and packing the dried new soles.

[0048] refer to...

Embodiment 2

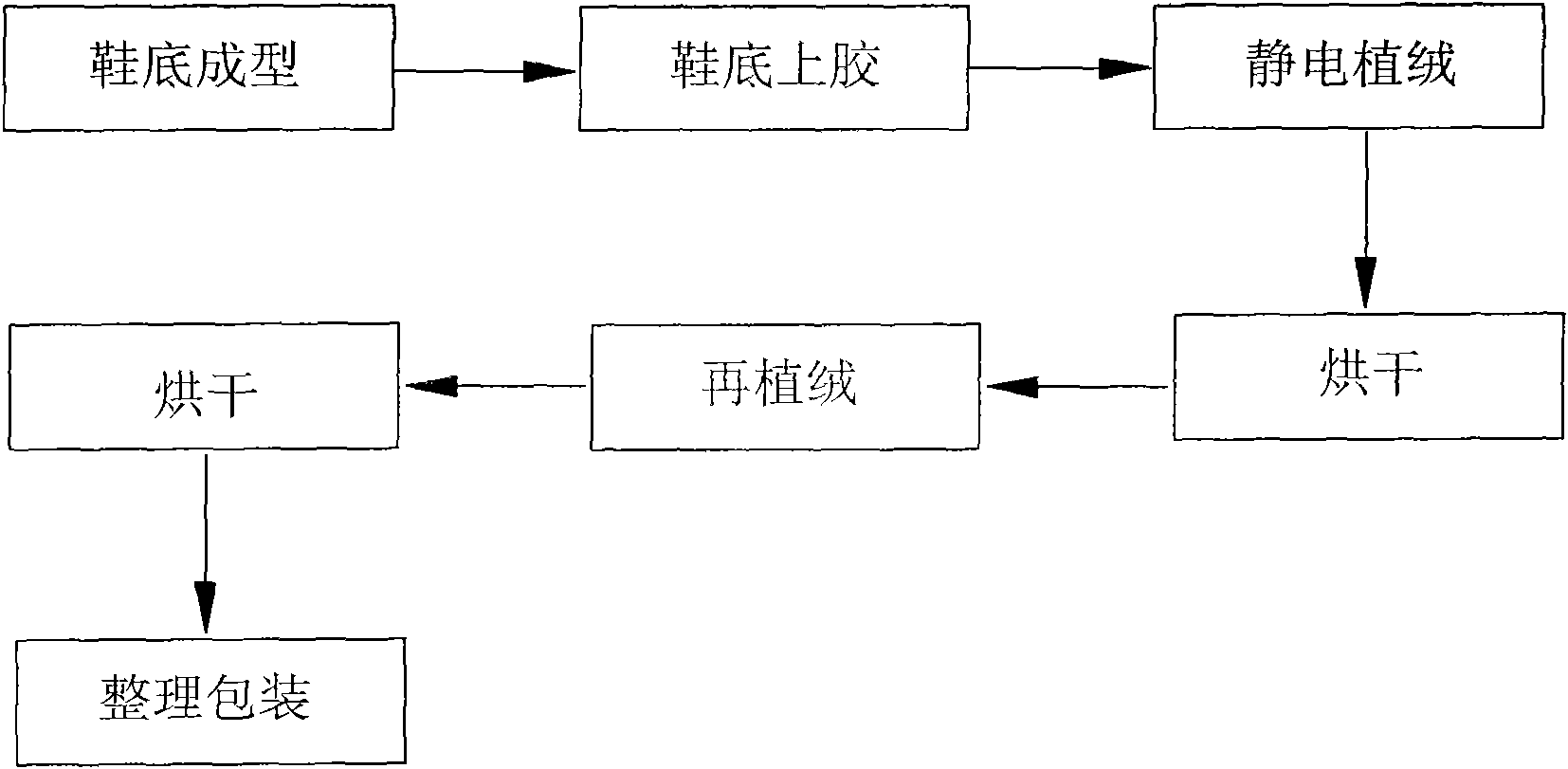

[0049] Embodiment 2: refer to figure 2 , present embodiment provides a kind of novel sole preparation method, it comprises the following steps:

[0050] (1) Sole molding: After melting the plastic, put it into the sole molding machine, and mold it to make the sole base material;

[0051] (2) Sole gluing: Put the sole base material into the gluing machine, apply the adhesive on the surface of the sole base material through the gluing machine, and after more than two treatments from thin to thick, the thickness is 0.06 ~0.16mm glue layer;

[0052] (3) Electrostatic flocking: Put the glued sole base material into the electrostatic flocking room for electrostatic flocking;

[0053] (4) Drying: Put the flocked sole base material into an oven with a temperature of 60-120°C to bake, take it out after drying, cool, and then brush the flocked material through a brush roller;

[0054] (5) flocking again: put the sole base material after step (4) drying into the electrostatic flockin...

Embodiment 3

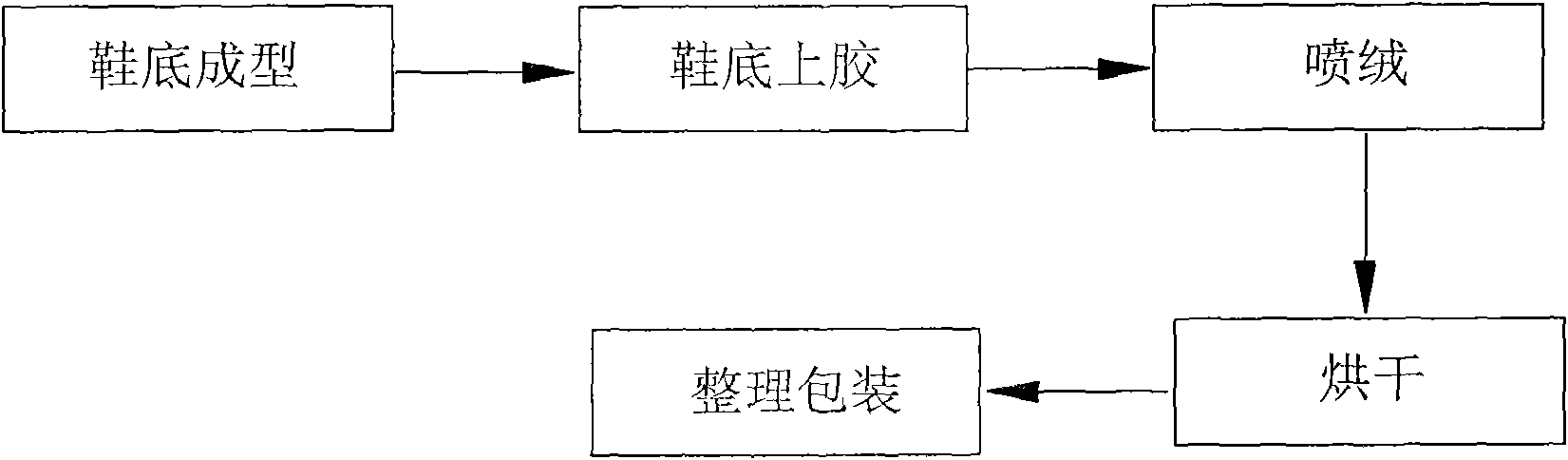

[0058] Embodiment 3: refer to image 3 , present embodiment provides a kind of novel sole preparation method, it comprises the following steps:

[0059] (1) Sole molding: After melting the plastic, put it into the sole molding machine, and mold it to make the sole base material;

[0060] (2) Sole gluing: Put the sole base material into the gluing machine, apply the adhesive on the surface of the sole base material through the gluing machine, and after more than two treatments from thin to thick, the thickness is 0.06 ~0.16mm glue layer;

[0061] (3) Spraying: Put the glued sole base material into the spraying room to carry out pneumatic spraying;

[0062] (4) Drying: Put the sprayed sole base material into an oven with a temperature of 60-120°C to bake, take it out after drying, cool it, and then brush it with a brush roller to get the finished product;

[0063] (5) Arranging and packaging: Arranging and packing the dried new soles.

[0064] refer to Figure 5 and Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com