Method for leading titanium alloy grinding wheel base body to keep dynamic balance in high-speed rotation

A high-speed rotation, titanium alloy technology, applied in the direction of bonded grinding wheels, metal processing equipment, abrasives, etc., can solve the problems of grinding wheel dynamic balance imbalance, and achieve the effect of solving dynamic balance imbalance, small vibration and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

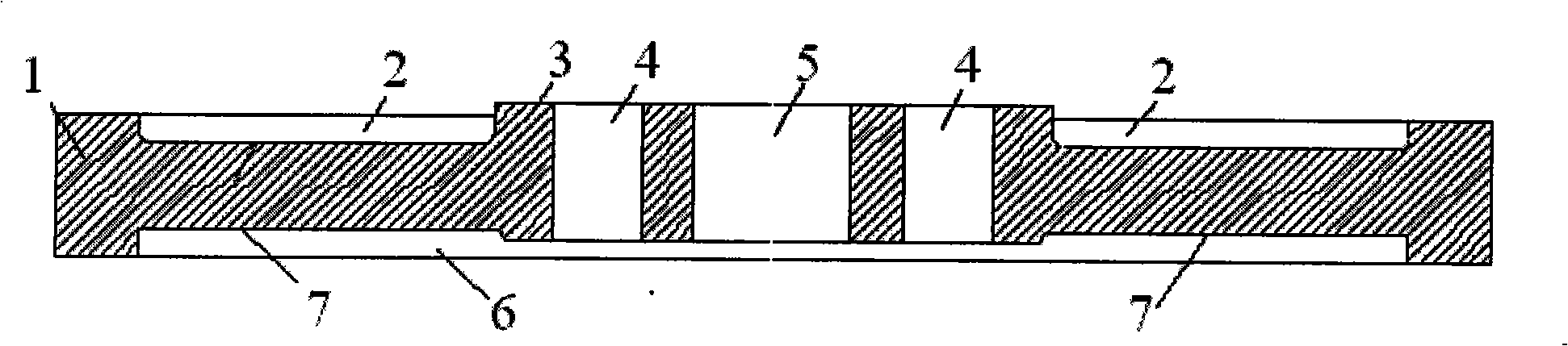

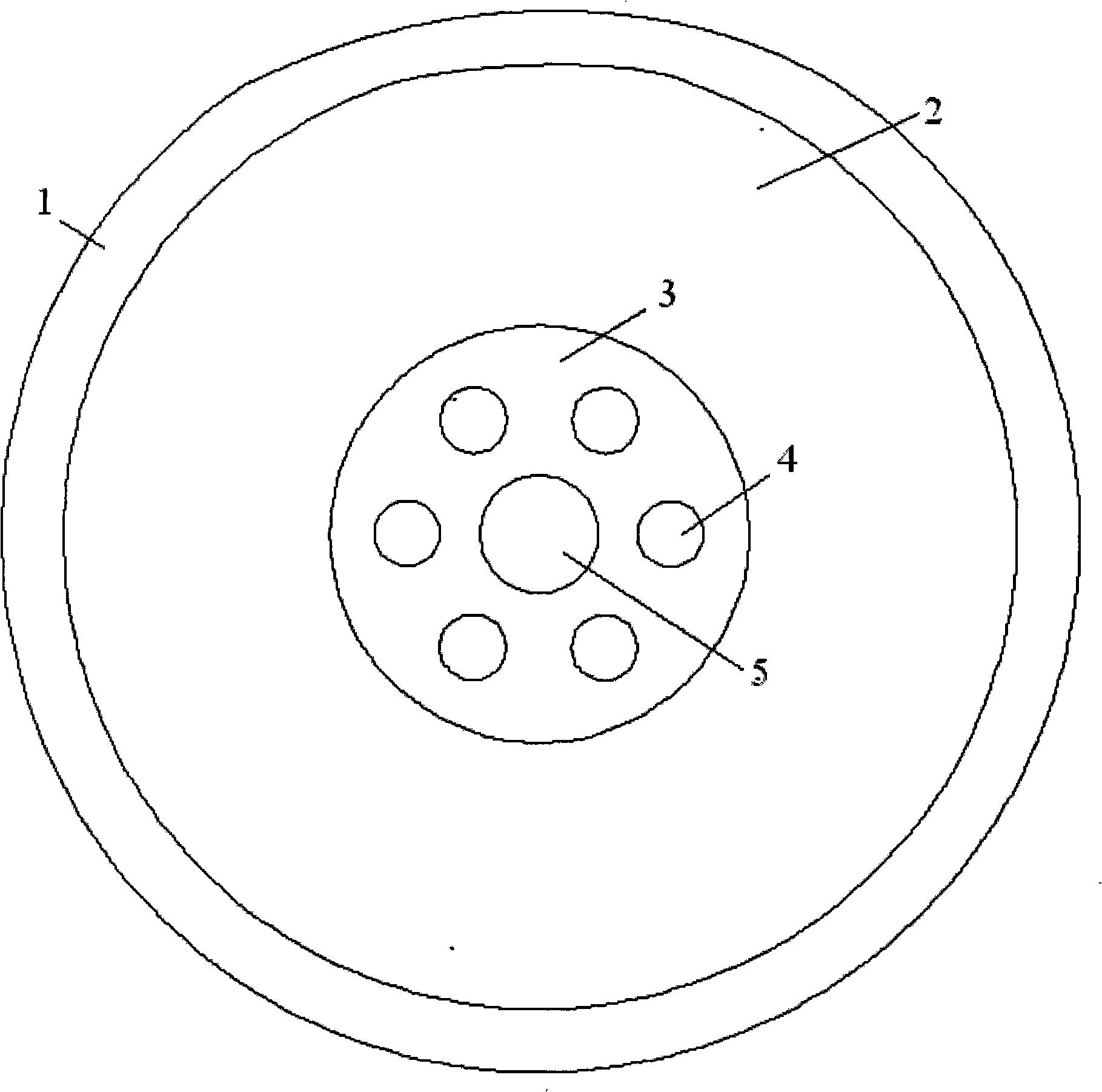

[0013] The existing grinding wheel base is a cylinder with a shaft hole 5 as the center, one end face of which is a plane, and the other end face is processed with a concave platform 6. The processing area around the shaft hole 5 is relatively large, so that the machining accuracy of both ends of the base body is low. As a result, the dynamic balance of the base body is out of balance and the vibration is large when it rotates at high speed.

[0014] The method of the present invention adopts the titanium alloy material to make the grinding wheel base body. Based on the structure of the existing grinding wheel base body, a circle of grooves A2 is arranged around the cylindrical surface at one end of the plane plane near the outer circumference of the base body. The groove A2 surrounds the base body. It is divided into the hub 3 part close to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com