Integral type shield cutterhead driving device

A technology of shield cutter head and driving device, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of cutter head driving device toll, reduce construction cost, save material resources and time resources, and improve competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

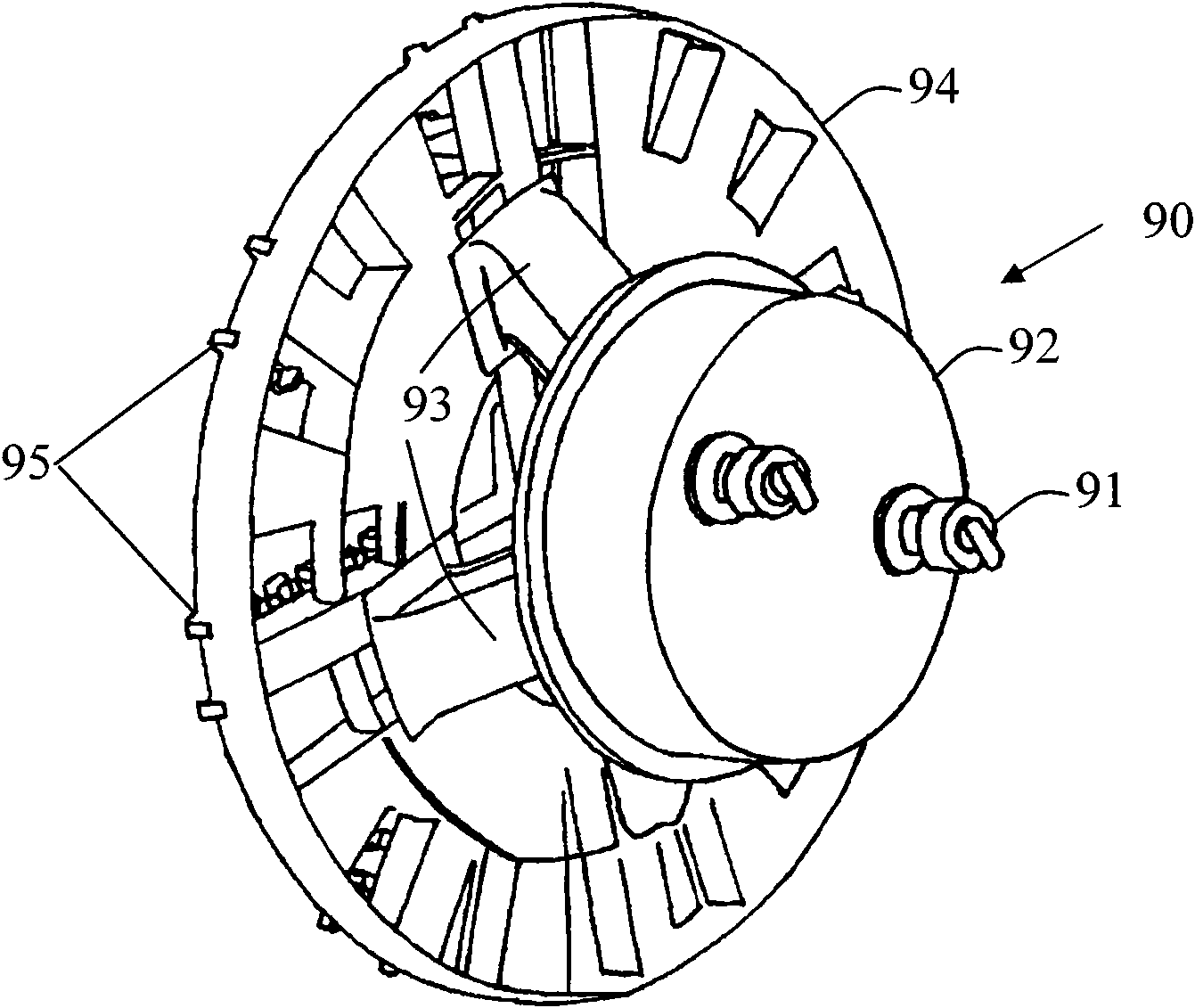

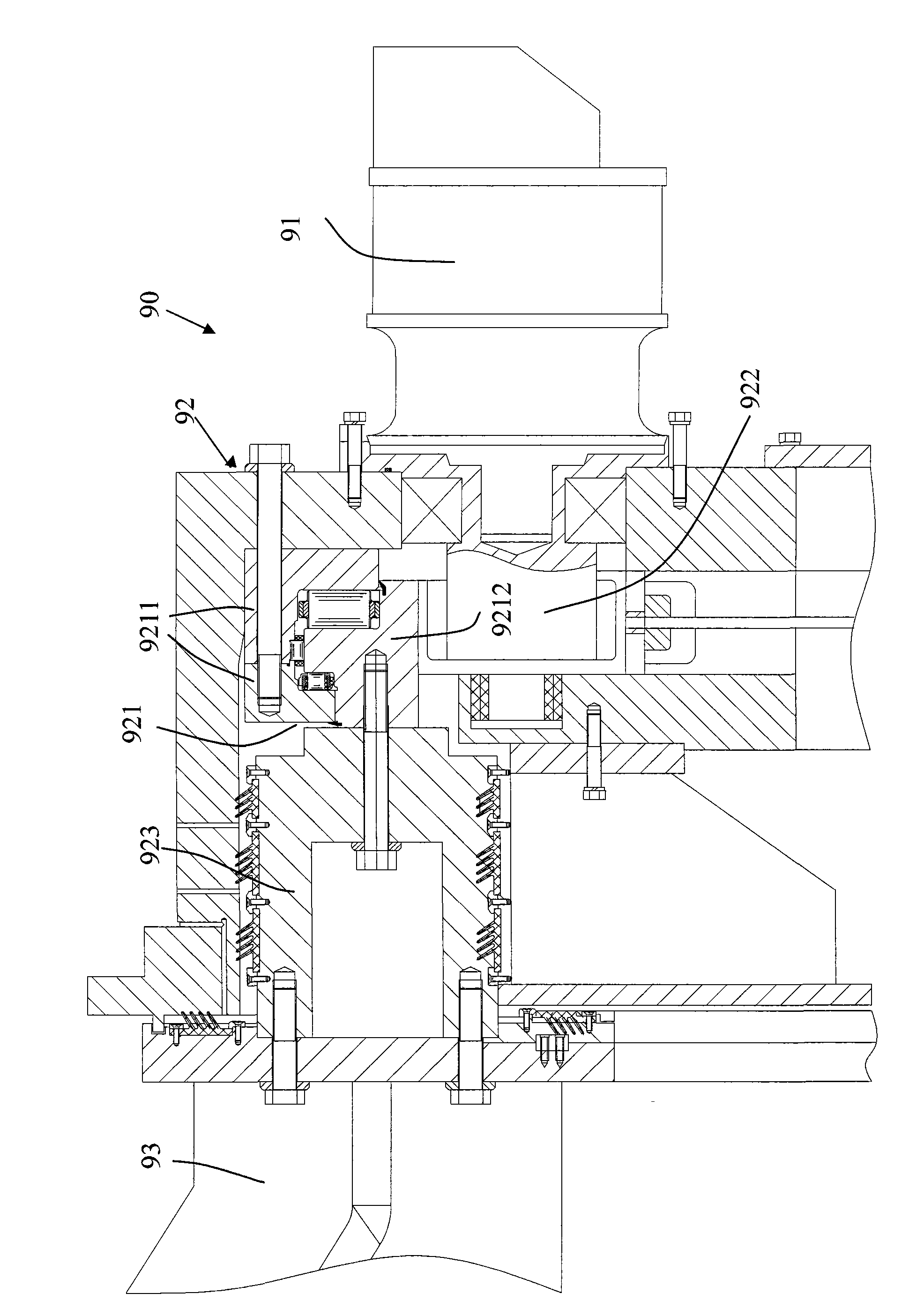

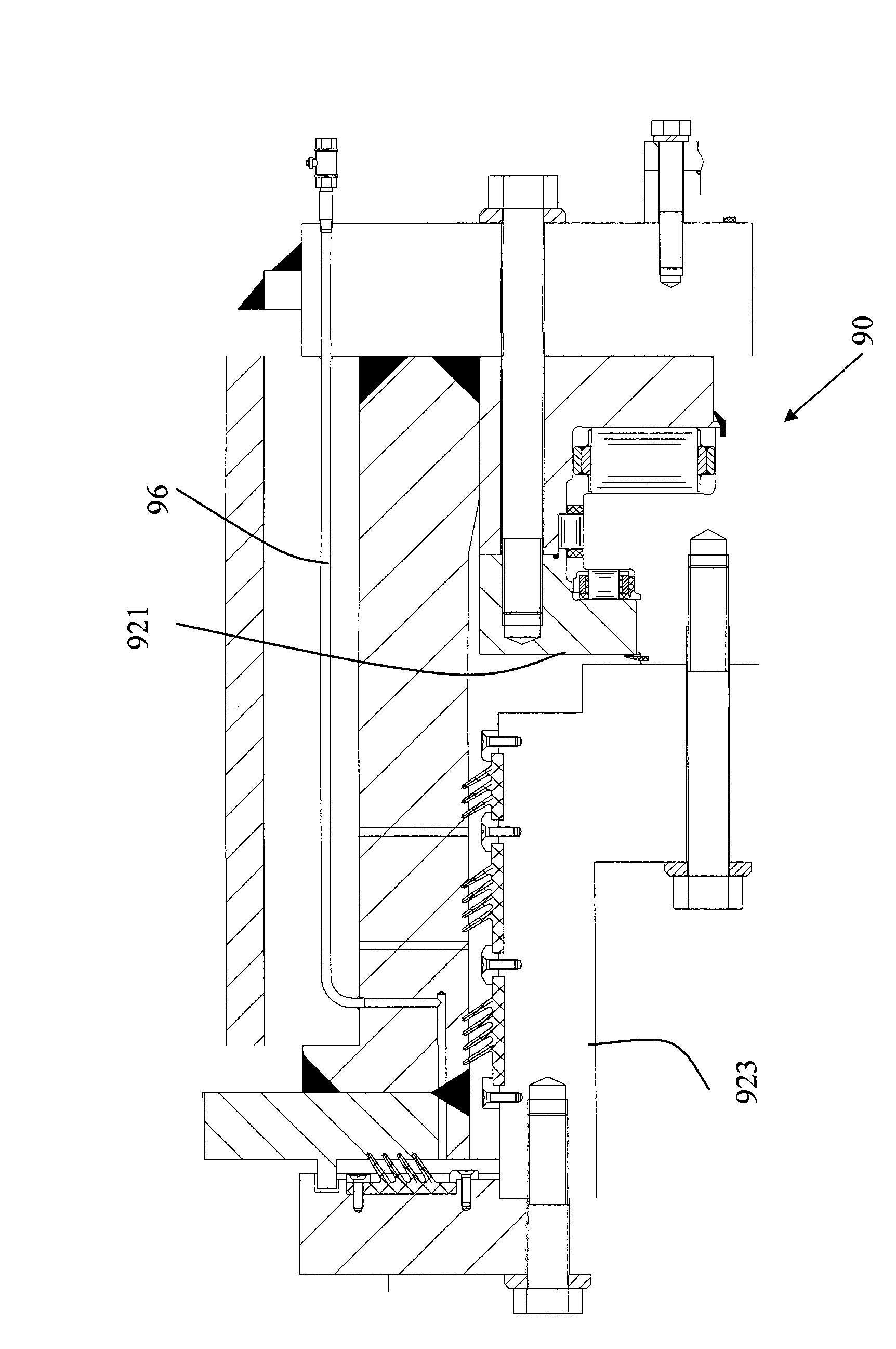

[0034] Such as Figure 4~5 As shown, it is an integral shield cutter head driving device of the present invention, which includes several motors 10, bearing bases 11, pinion gears 12 driven by the motors 10, large bearings 20, and large bearings 20 include bearing inner rings 22 and bearing outer rings. Ring 24, the bearing ring 30 fixedly connected with the bearing inner ring 22 of the large bearing 20, the outer seal seat 31 located outside the bearing ring 30, the pinion 12 and the teeth on the inner side of the bearing inner ring 22 of the large bearing 20 form internal meshing , the bearing outer ring 22 and the outer sealing seat 31 of the large bearing 20 are connected to the bearing base 11 with bolts 21, an outer sealing ring 32 is provided between the force ring 30 and the outer sealing seat 31, and the front end of the outer sealing seat 31 is provided Plane seal 33 is arranged; And the corbel 35 driven by force ring 30, the cutterhead fixed on the corbel 35 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com