One-dimensional evaluation method of combustion efficiency for scramjet engine

An evaluation method and combustion efficiency technology, applied in the field of one-dimensional evaluation of the combustion efficiency of the scramjet combustion chamber, can solve the problem of ignoring the influence of fuel injection momentum and energy changes, ignoring wall friction and endothermic effect, and limiting the general method. adaptability and other issues to achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

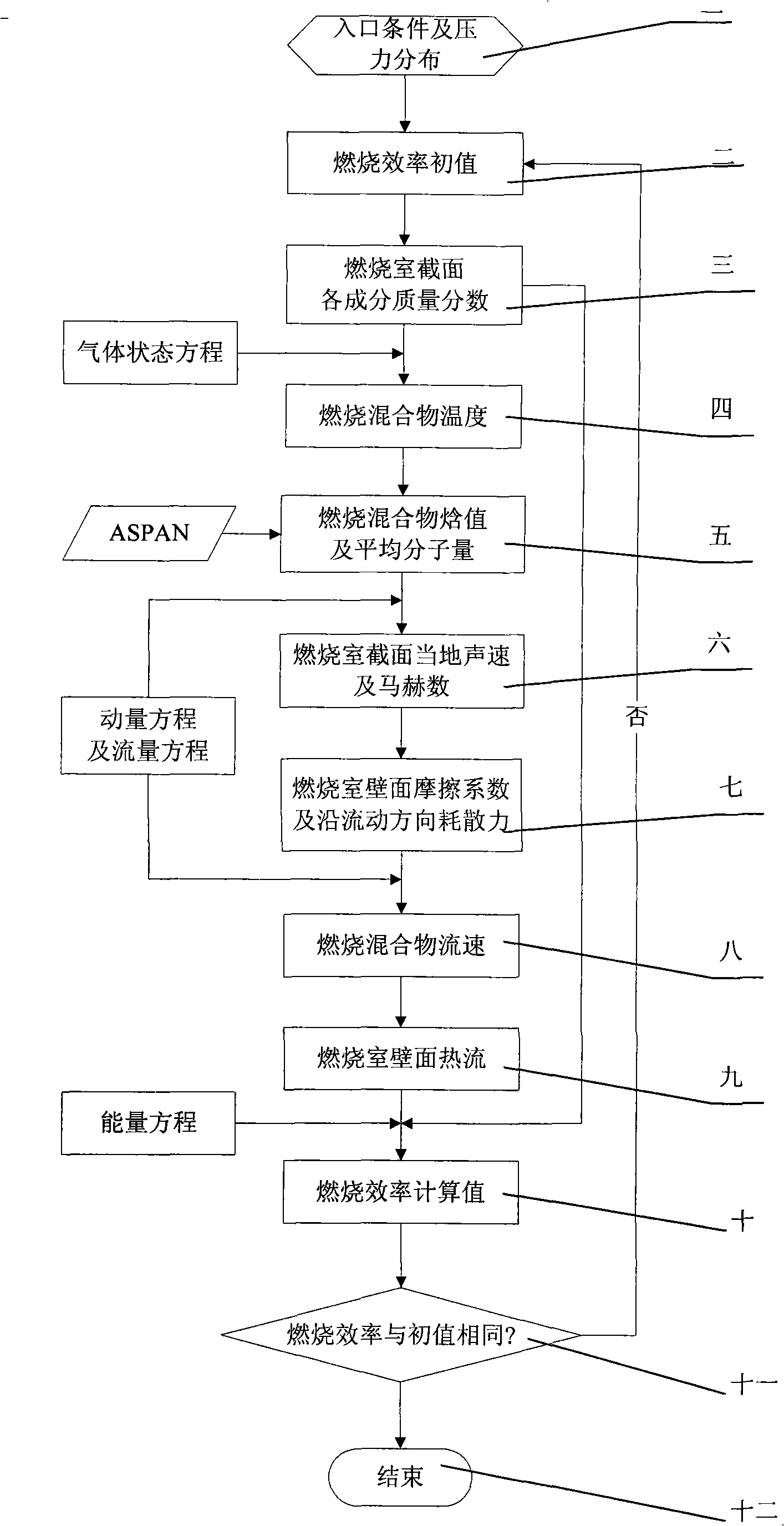

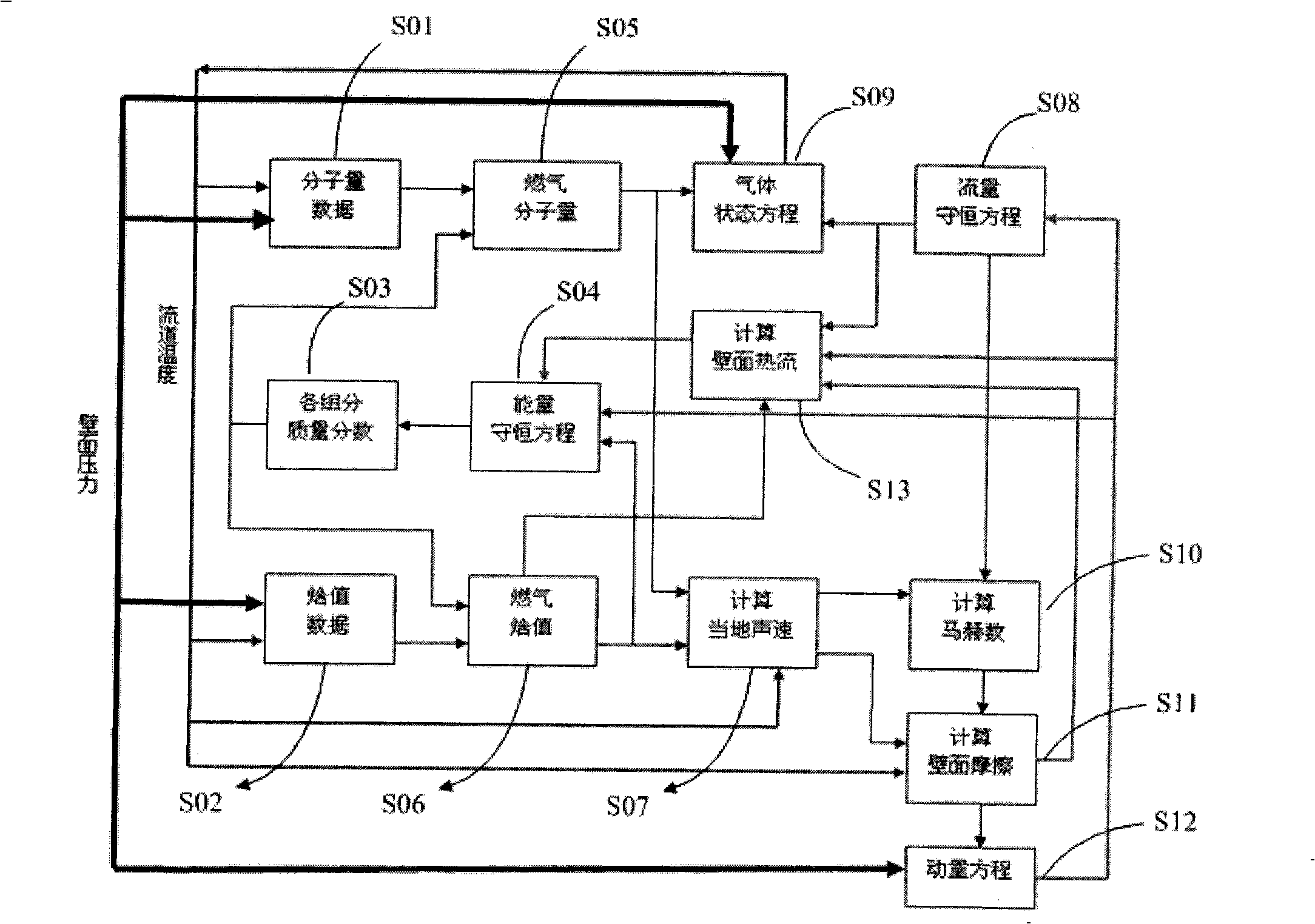

[0045] Specific implementation mode one: as figure 1 As shown, the one-dimensional evaluation method of the combustion efficiency of the scramjet described in this embodiment is realized according to the following steps:

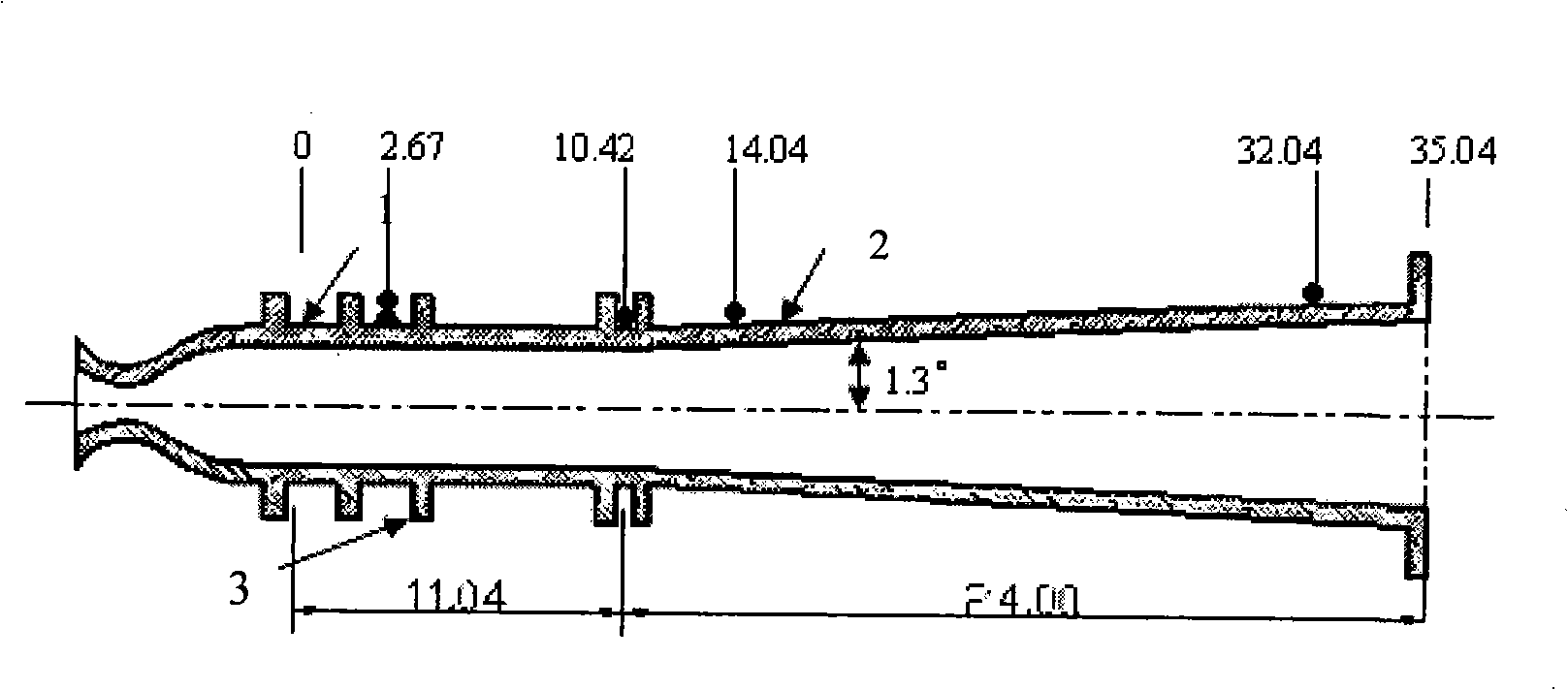

[0046] Step 1. Determine the inlet conditions and pressure distribution of the combustion chamber: Obtain the pressure distribution of the scramjet combustion chamber wall through experiments or numerical simulations, and establish the molecular weight and enthalpy database of each component in the combustion chamber according to the physical property analysis software (such as ASPEN) , establish the functional relationship μ(p, T, α) and H(p, T, α) of molecular weight and enthalpy with pressure, temperature and mixture composition; given the total mass flow rate and the fraction of each component at the entrance of the combustion chamber, determine G τ , G o , L oτ ,α,H BX * and I BX , using the mutual transformation between the combustion efficiency ...

specific Embodiment approach 2

[0082] Specific implementation mode two: In step six in this embodiment mode, the equilibrium dissociated gas method is used for calculating the local sound velocity and Mach number of the combustion chamber section:

[0083] h kc =g τkc h τ (p τkc ,T kc ,α=0)+g okc h o (p okc ,T kc ,α=∞)+g nckc h nc (p nckc ,T kc ,α=1) (10)

[0084] c p = ( ∂ H kc ∂ T kc ) p kc - - - ( 11 )

[0085] c v = c p - R ...

specific Embodiment approach 3

[0090] Specific implementation mode three: In step seven of this implementation mode, the friction loss on the wall surface of the combustion chamber adopts the semi-empirical formula of the flat plate non-gradient turbulent boundary layer:

[0091] 0.242 1 - ω - β c f β [ arcsin β + ω 2 β 1 + ω 2 4 β - arcsin ω ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com