Electrode structure of memory capacitor and method for manufacturing memory capacitor structure

A technology of electrode structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of unstable capacitor structure, contact phenomenon, etc., to increase the surface area of the capacitor, not easy to contact short circuit, and improve the capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

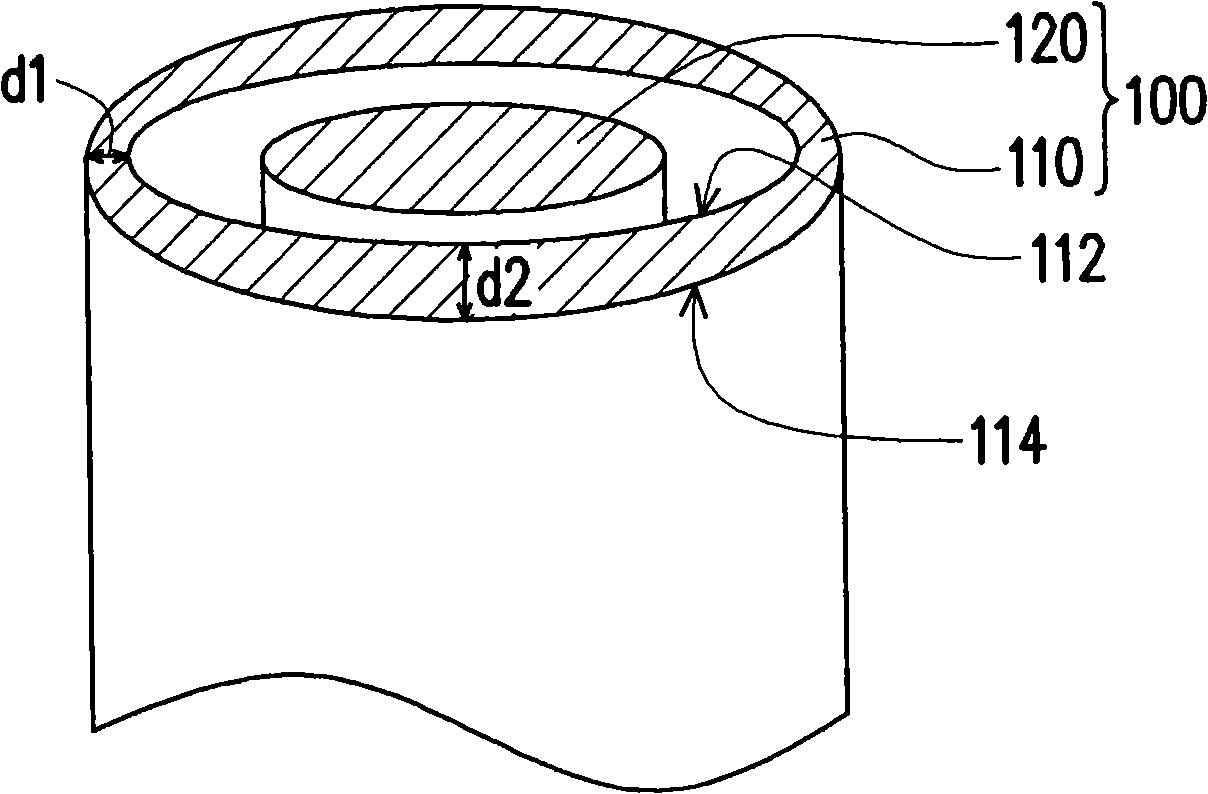

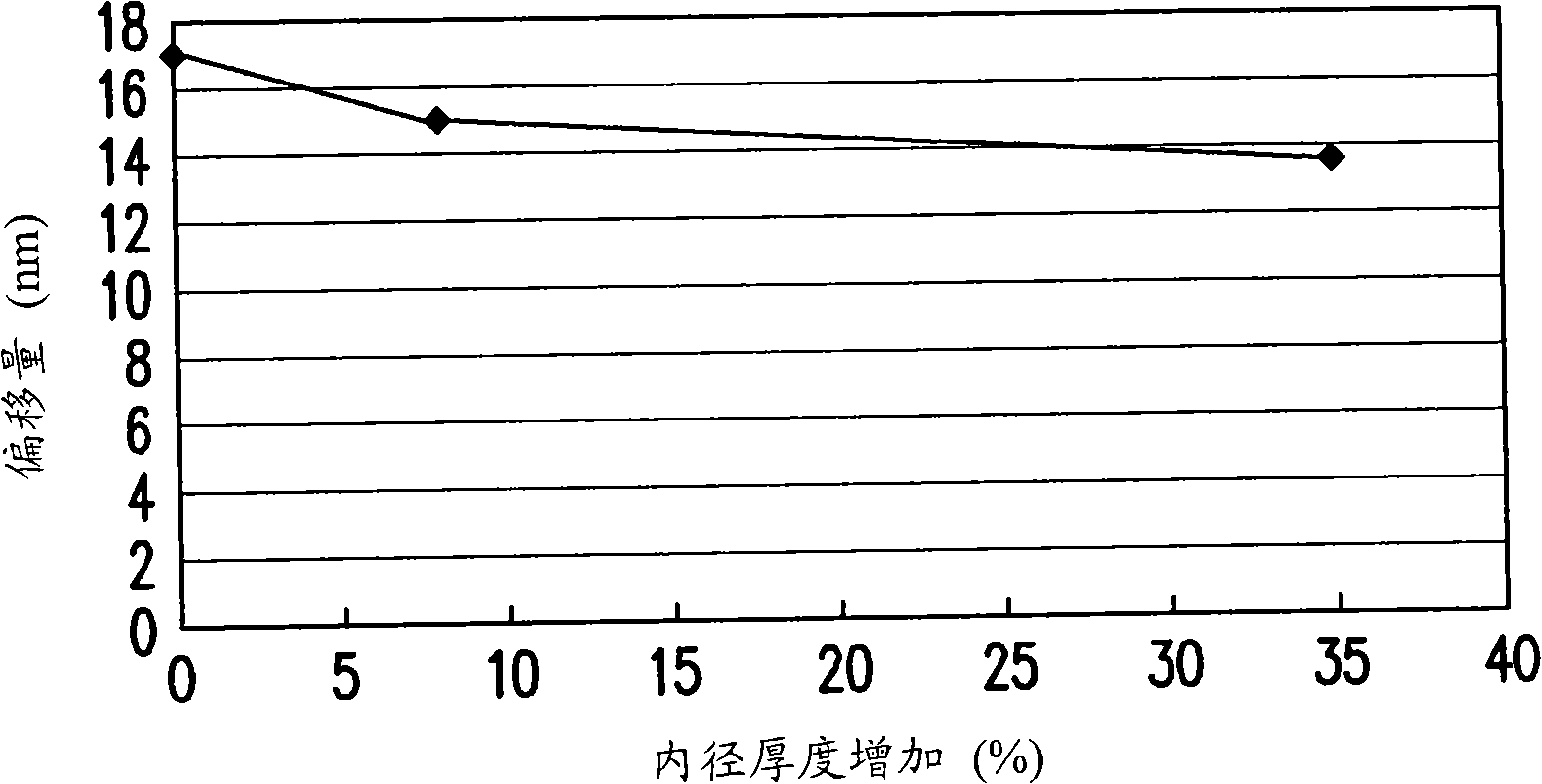

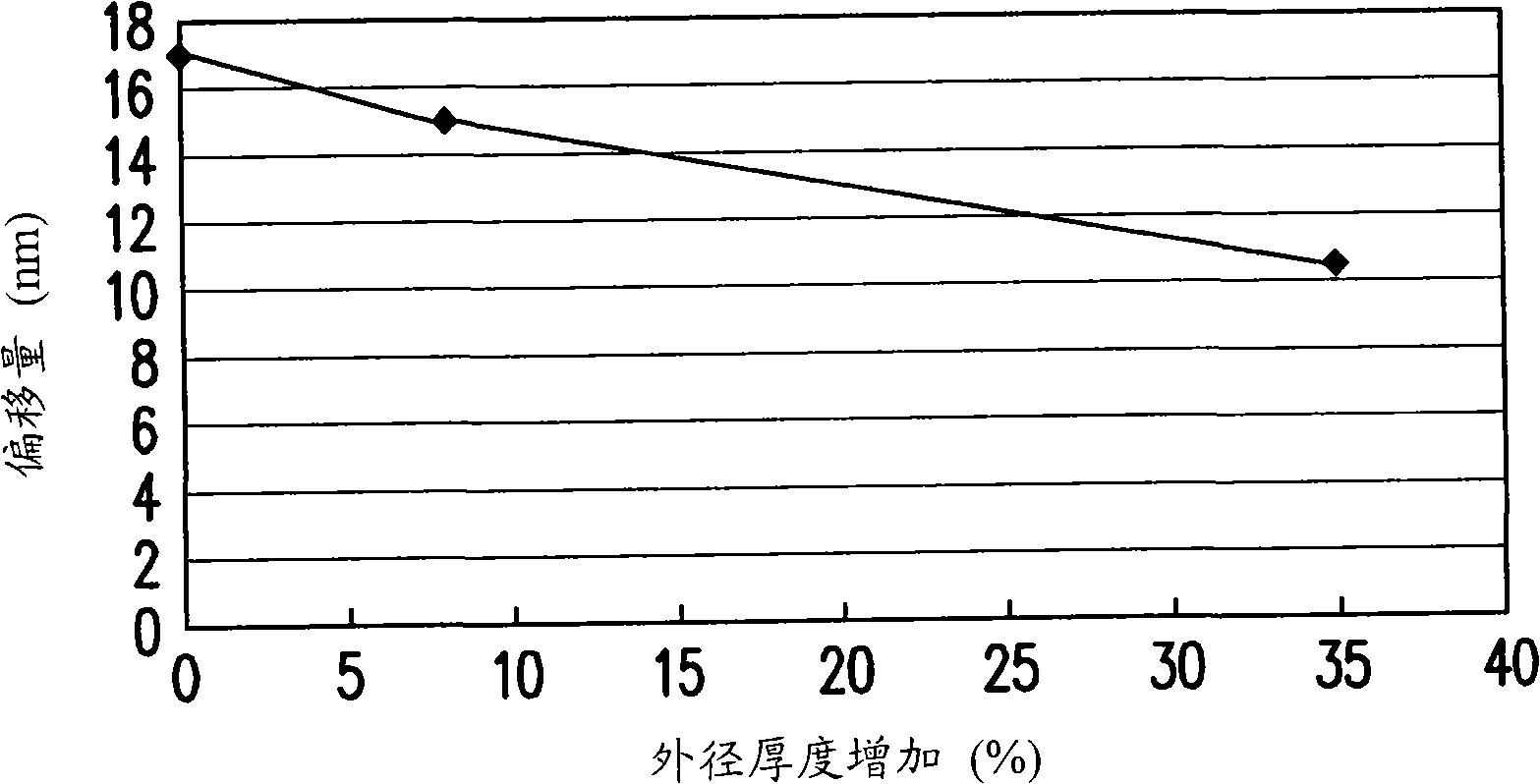

[0029] figure 1 It is a three-dimensional schematic diagram of an electrode structure of a memory capacitor according to an embodiment of the present invention, and FIG. 2 is a graph showing the influence of the thickness variation of the lower electrode on the strength of the capacitor structure.

[0030] Please refer to figure 1 , the lower electrode 100 of the storage capacitor is a composite electrode structure composed of an outer annular tube 110 and a central cylinder 120 . The radial section of the outer annular tube body 110 is elliptical, and has a thickness d1 along the major axis and a thickness d2 along the minor axis. In order to improve the structural displacement strength, the outer annular tube body 110 adopts an elliptical cross-section design, which can effectively reduce the probability of capacitance displacement compared with known cylindrical capacitors with weak structures. In addition, when fabricating the lower electrode 100 of the storage capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com