Thin film transistor substrate and manufacturing process thereof

A technology of thin film transistor and manufacturing process, applied in the field of thin film transistor substrate and its manufacturing process, can solve the problems of low aperture ratio of thin film transistor substrate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

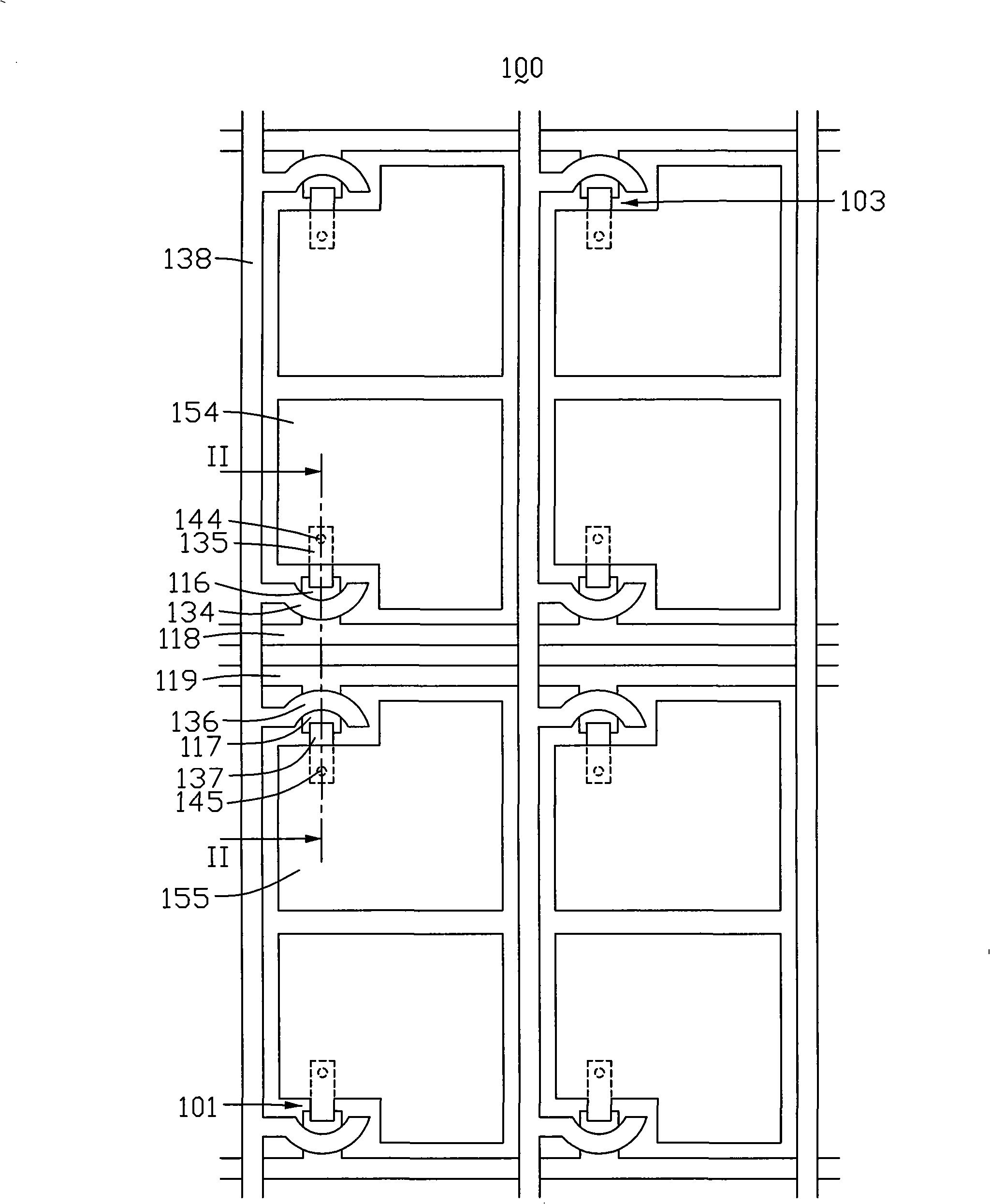

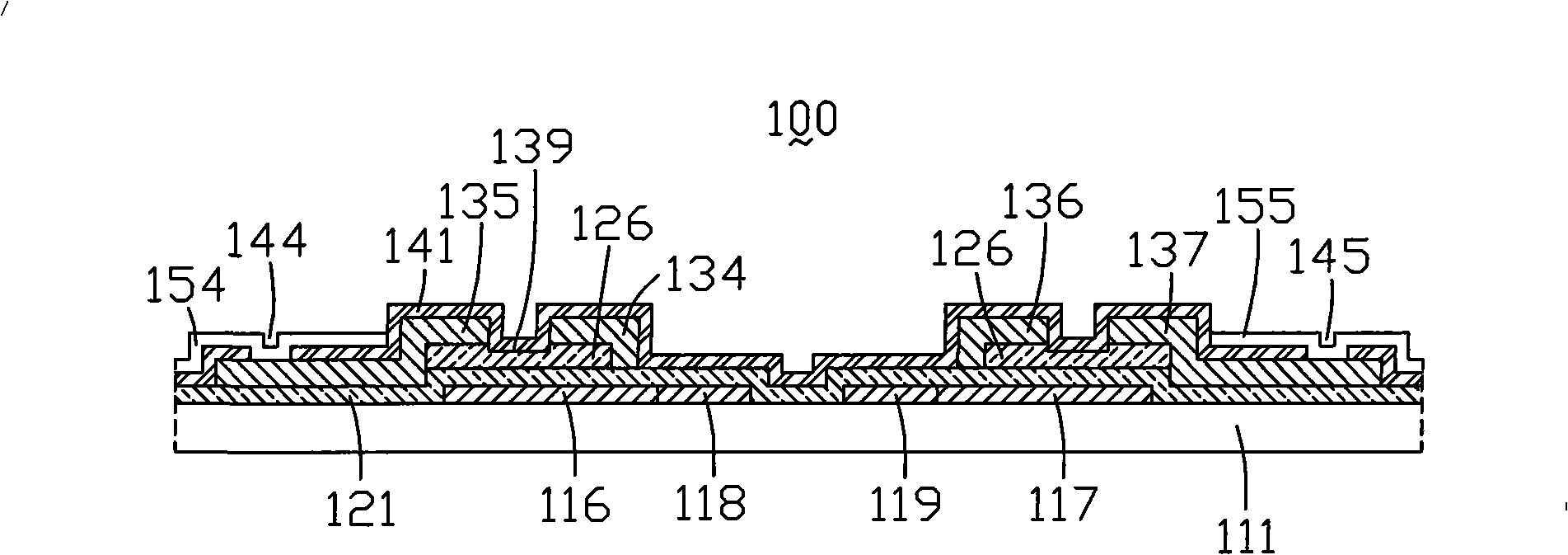

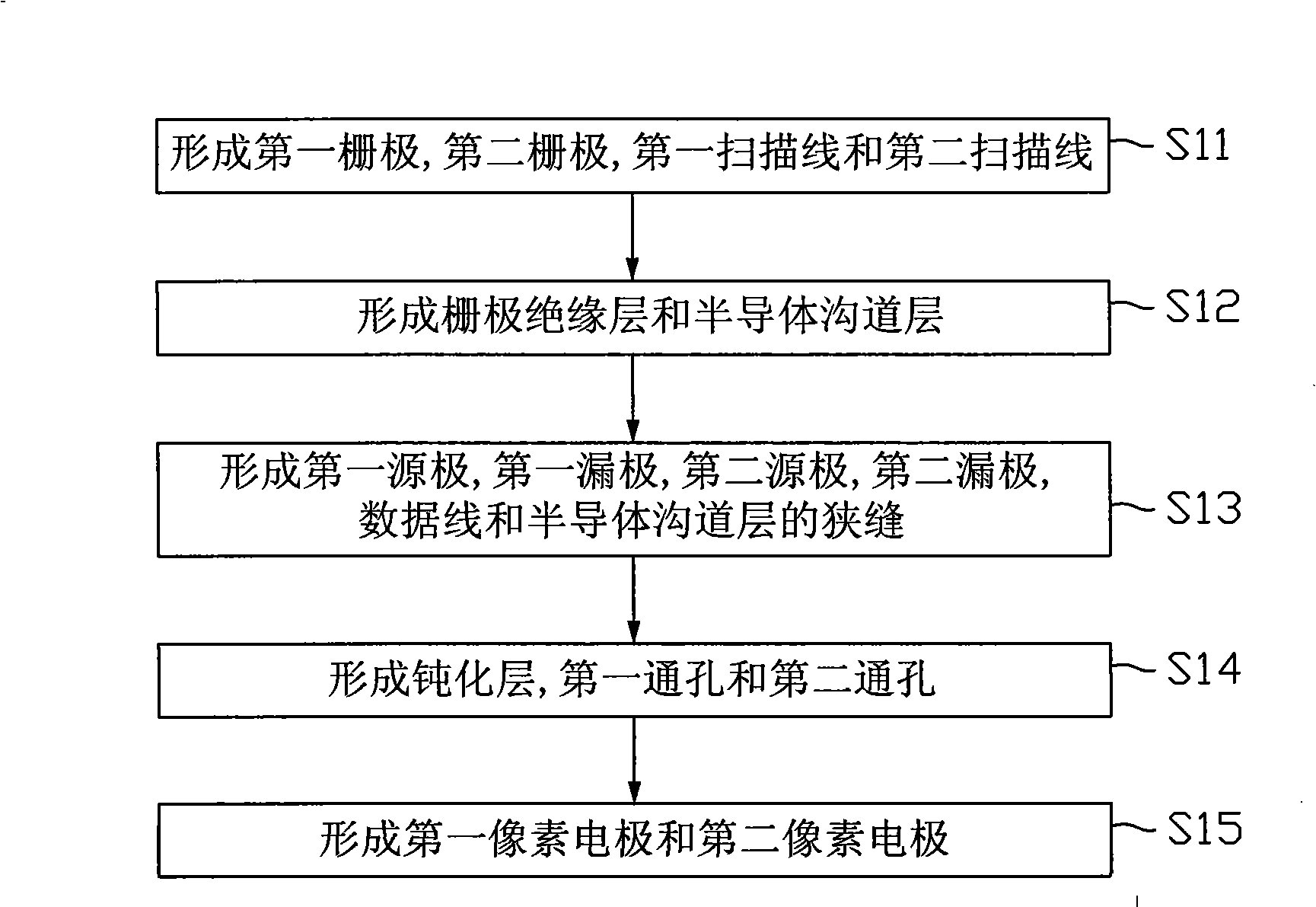

[0031] refer to Figure 4 , is a partial plan view of a preferred embodiment of the thin film transistor substrate of the present invention. The thin film transistor substrate 200 includes a plurality of first scan lines 218, a plurality of second scan lines 259, a plurality of data lines 238, a plurality of first thin film transistors 201, a plurality of second thin film transistors 203, and a plurality of first pixel electrodes 254 , a plurality of second pixel electrodes 255 , a plurality of first through holes 244 , a plurality of second through holes 245 and a plurality of third through holes 246 .

[0032]The plurality of first scan lines 218 are parallel to each other, the plurality of second scan lines 259 are parallel to the first scan lines 218, the second scan lines 259 correspond to the first scan lines 218 one-to-one and two corresponding scans The wires 218, 259 are insulated and overlapped. Wherein, the second scan line 259 is located directly above the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com