LS control arrangement

A control device and fluid control technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve troublesome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

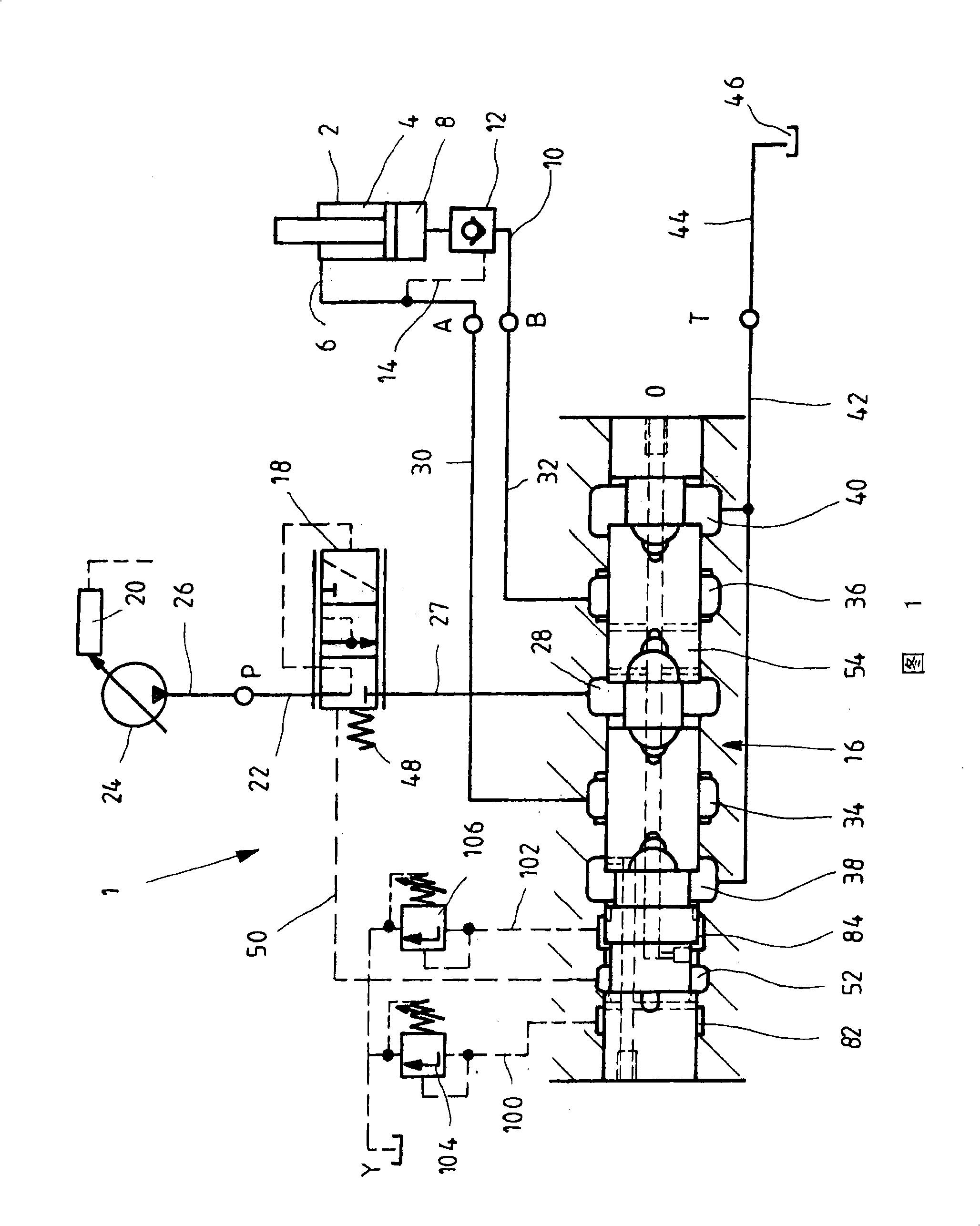

[0027] figure 1The shown system diagram of an LS control device can be designed, for example, as a valve plate of a mobile control block (Mobilsteuerblock) for triggering the hydraulic loading of the bending arm of a mobile work tool, such as a truck-loading crane . Such an LS control device 1 has a pressure connection P, a tank connection T as well as two working connections A, B and at least one leakage connection Y as well as a not shown LS connection. A load is connected to the two working joints A and B, here it is a differential cylinder 2, its annular chamber 4 is connected to the joint A through a working pipeline 6, and its bottom side cylinder chamber 8 is passed through a working The pipeline 10 is connected to the working joint B. In the working line 10 there is a lowering brake valve 12, which can be released by the pressure in the working line 6 when the differential cylinder 2 is moved in, so that the pressure medium can flow out of the then reduced cylinder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com