Method or device for taking-out and shape-forming of coil

A technology for taking out devices and coils, which is applied in coil manufacturing, electromechanical devices, electric components, etc., and can solve problems such as coil deformation, coils that cannot reach the specified size, and prolonging production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

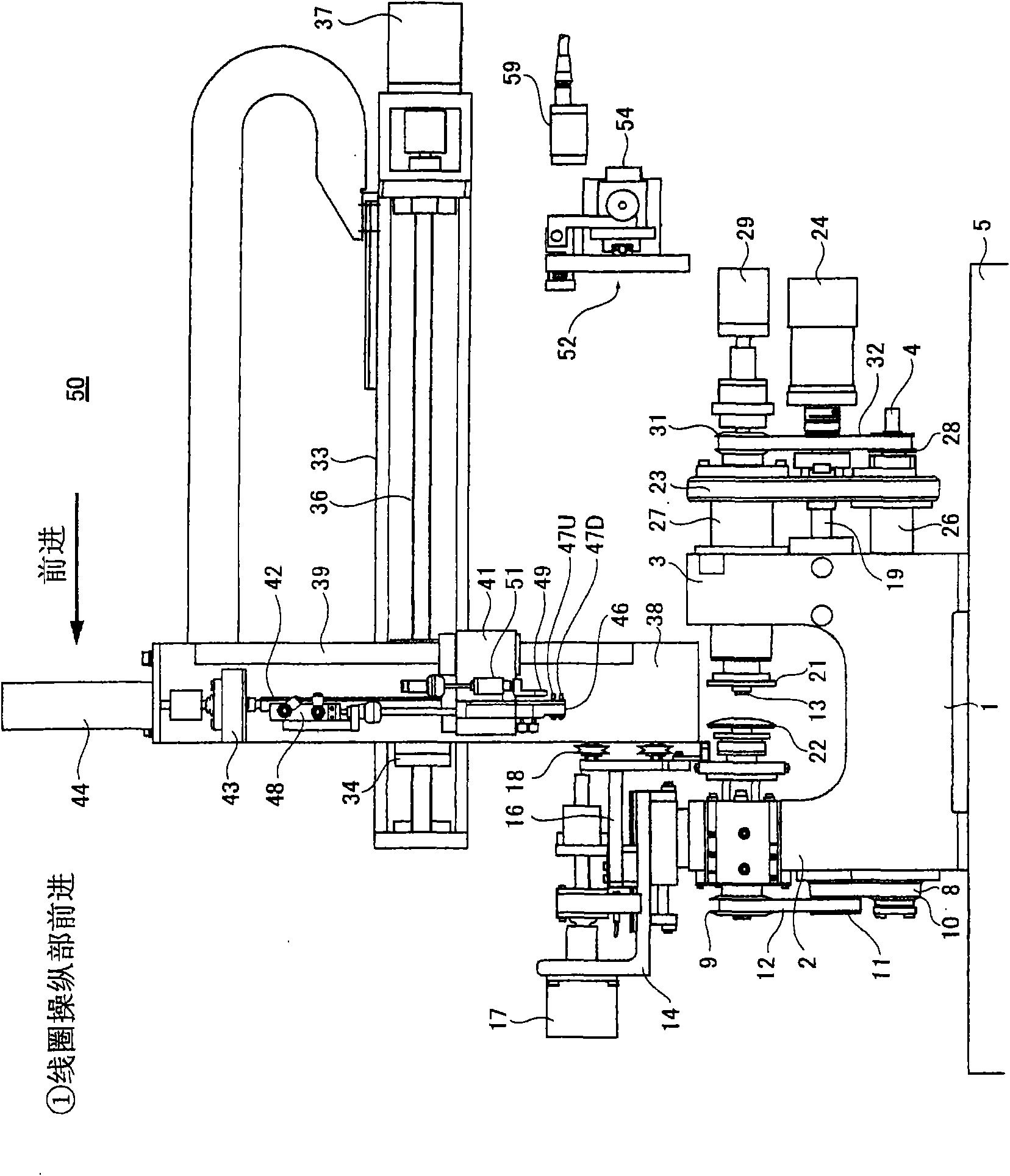

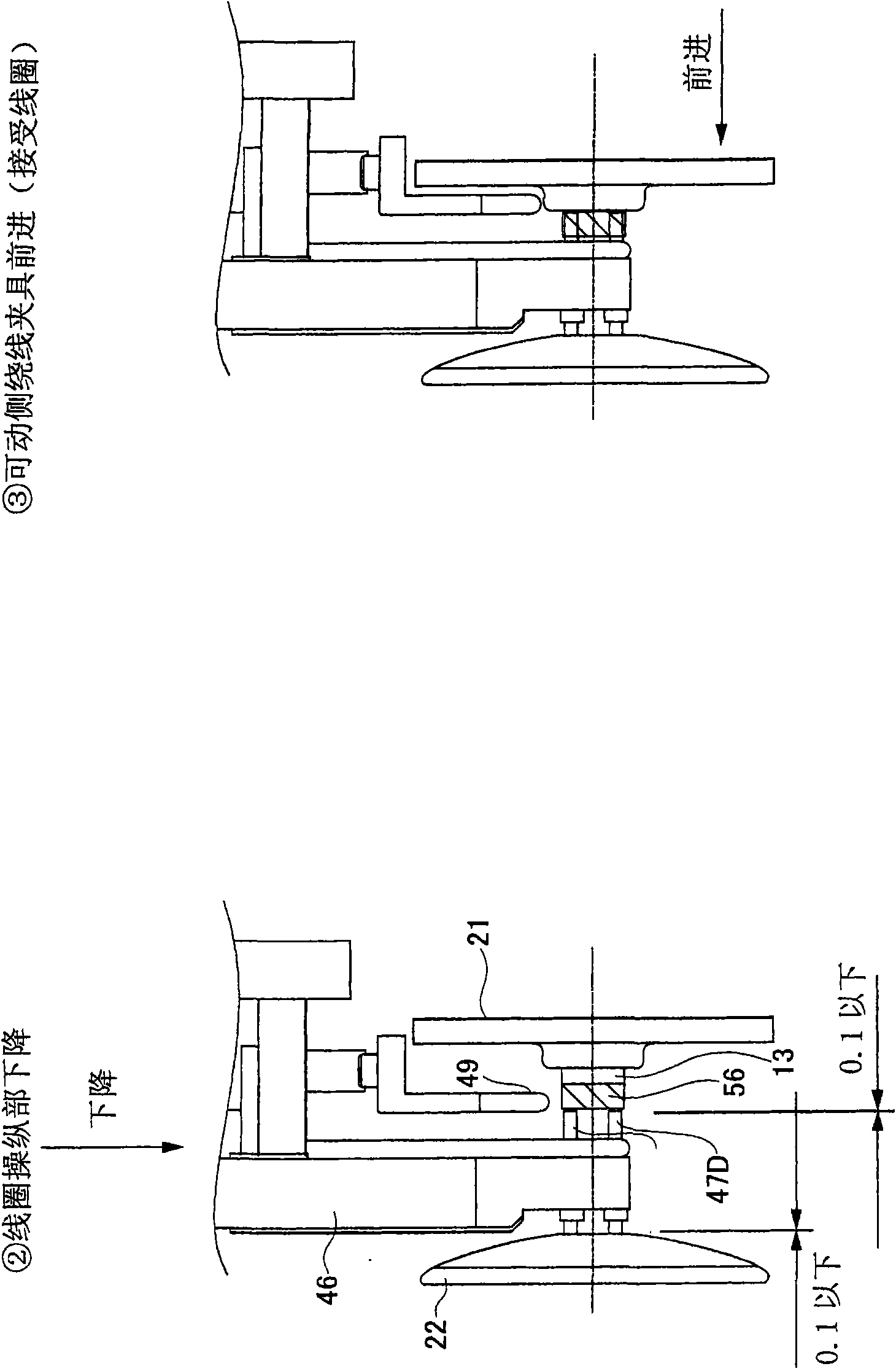

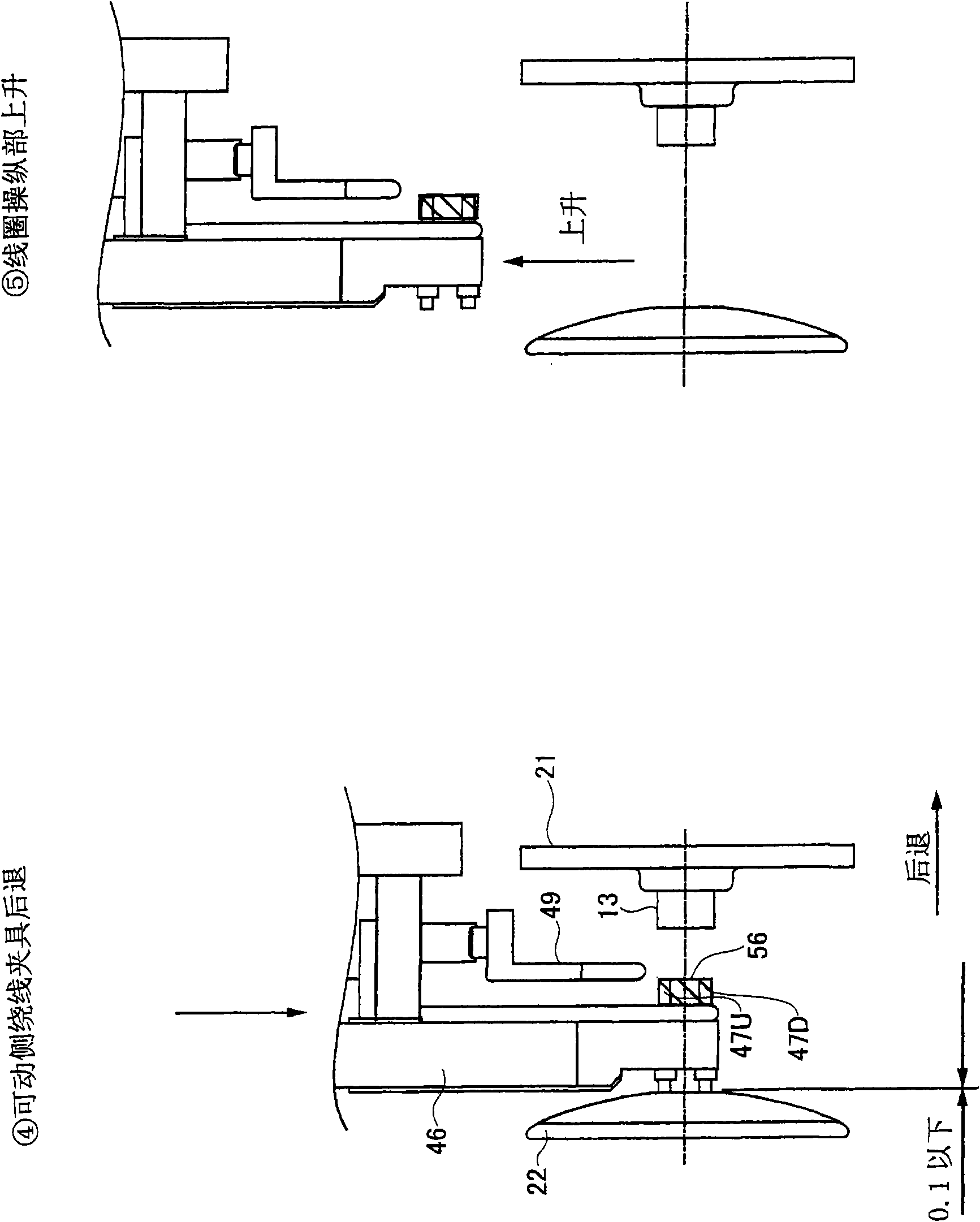

[0127] Hereinafter, the present invention will be described in detail based on the illustrated embodiment examples. figure 1 It is a front view of the coil forming apparatus 50 which concerns on embodiment of this invention. In addition, in this device 50, the structure of the winding machine part is described in detail in, for example, Japanese Patent Application Laid-Open No. 2005-116657, Japanese Patent Laid-Open No. 2001-358029 and Japanese Patent Laid-Open No. 10 related to the application of the present inventor. - Bulletin No. 304628, etc. Therefore, only the parts considered to be necessary for the description of the embodiment example will be described here.

[0128] figure 1 It is the front of embodiment example 50. 1 is the main shaft body, which is arranged on the casing 5, the left side of which is provided with the left side of the main shaft body 2 (fixed side), and the right side is provided with the right side of the main shaft body 3 (movable side). At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com