No-frame fusible alloy sprinkler nozzle

A technology of fusible alloys and nozzles, which can be used in fire rescue and other fields, and can solve problems such as fatigue and accumulation of elastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

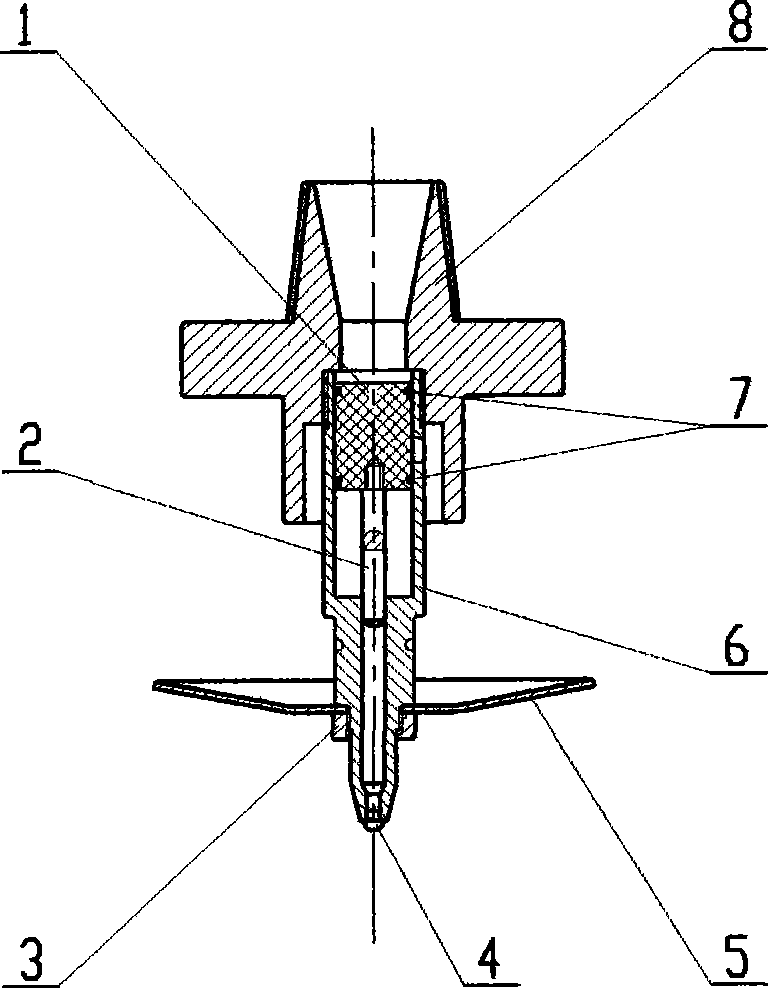

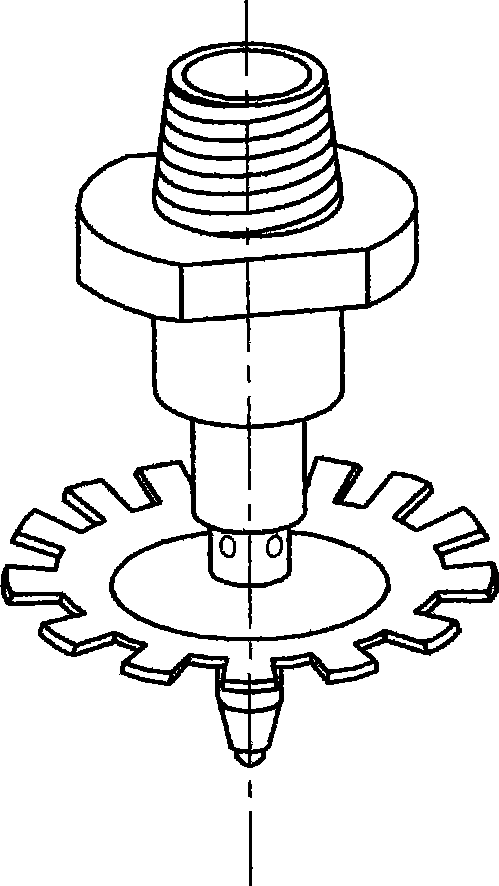

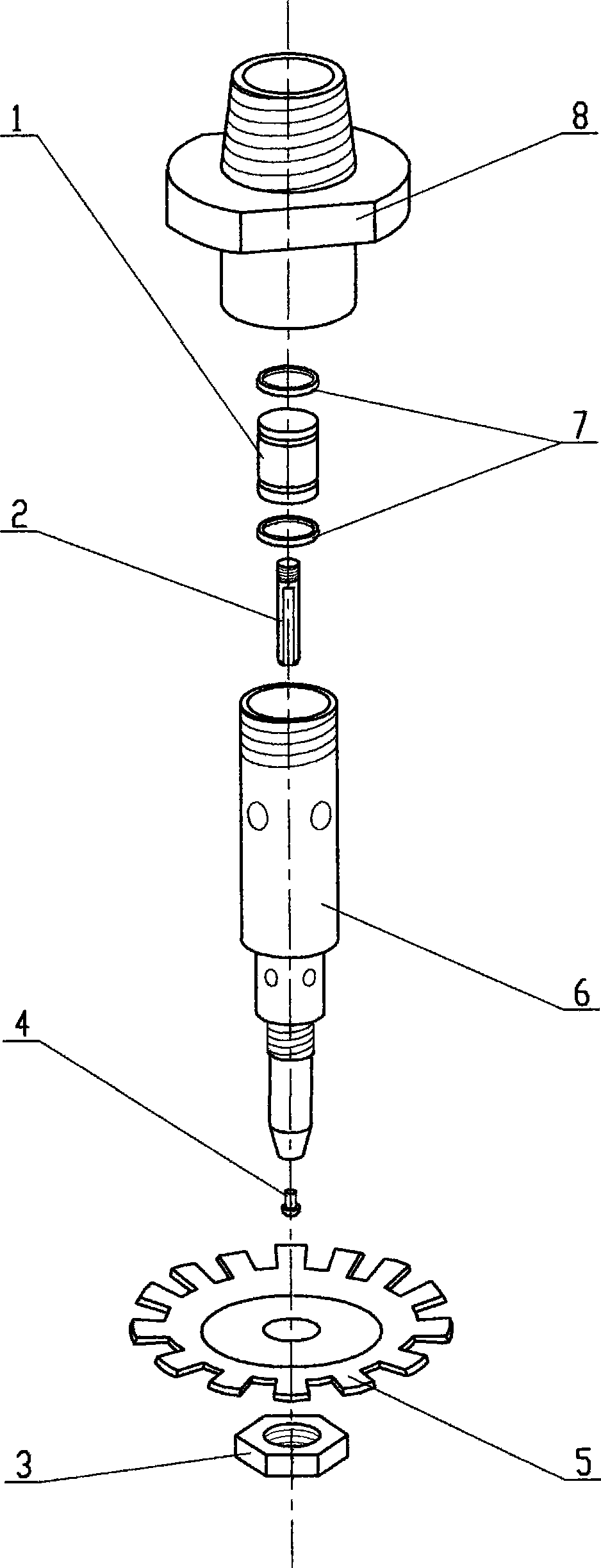

[0011] As shown in the accompanying drawings: the present invention includes a valve core, a valve stem, a nut, a fusible head, a splash plate, a valve body, a sealing ring, and a nozzle body. 1. Valve core, 2. Valve stem, 3. Nut, 4. Fusible head, 5. Splash plate, 6. Valve body, 7. Seal ring, 8. Nozzle body. The nozzle body [8] has a stepped cylindrical shape, one end is a tapered thread, and is tightly connected with the inner joint on the fire water pipe. There is a conical hole in the middle, and the inner hole at the other end is stepped. The middle part is provided with an internal thread and the valve body [6] Sealed connection, the port has a larger diameter, and maintains a certain flow cross section with the valve body [6]; a symmetrical plane for a wrench is provided at the large diameter of the outer circle. The valve body [6] is in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap