Method for preparing isopentenol from 3-methyl-3-butenol

A technology of isopentenol and butenol, applied in the direction of isomerization preparation, organic chemistry, etc., can solve the problems of increased production cost, low reactivity, capacity constraints, etc., and achieve mild reaction conditions, shortened reaction time, high activity The effect of low component content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

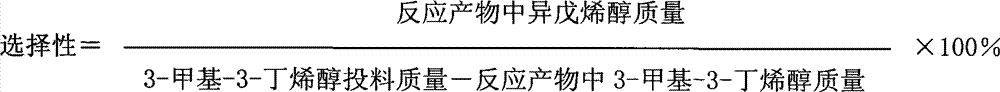

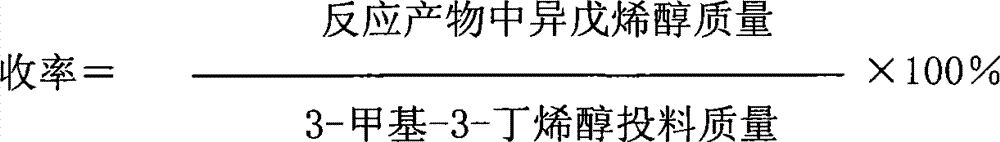

[0017] Add 30 grams of 3-methyl-3-butenol into a 100 ml three-necked flask, and place the flask in an oil bath. Add the catalyst according to the required ratio, the catalyst is Al 2 o 3 It is used as a carrier to load the active component metal Pd, and the particle size of the catalyst is 80-200 mesh. Under normal pressure, hydrogen or nitrogen-hydrogen mixed gas is continuously introduced into the material at a flow rate of 25ml / min. After the air in the flask is removed, the material is stirred and heated, and kept at a constant temperature after being heated to the required reaction temperature. until the end of the reaction. After the reaction product is cooled, the catalyst is removed by filtration, the composition of the reaction solution is obtained through gas chromatography analysis, and the selectivity and yield of the product prenol are calculated.

[0018] The catalyst active component content, catalyst consumption and concrete reaction conditions that each emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com