Formaldehyde free brewage art

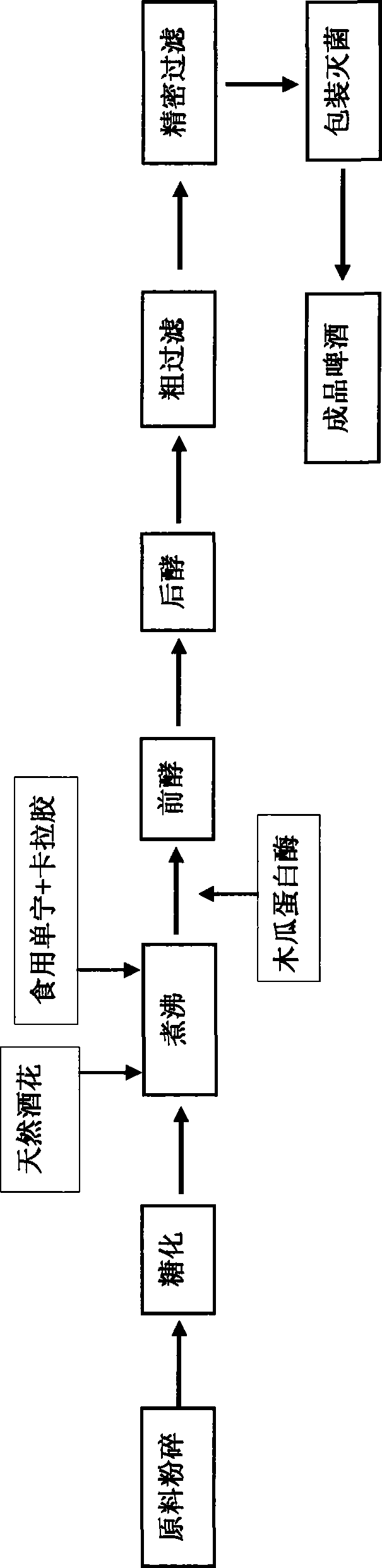

A beer and process technology, which is applied in the development field of formaldehyde-free beer brewing process to achieve the effects of mellow taste, prolongation of appearance indicators, and improvement of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] 1. Select the main raw materials of high-quality beer malt, hops, yeast, and water. The malt requirement is premium grade malt. The yeast is required to be less than 5 generations of yeast, and the water is required to be special beer brewing treatment water. The hops are SAAZ polyphenol hops from the Czech Republic and domestic bitter hops, and first-grade new rice is used as auxiliary materials.

[0013] 2. Low-temperature cutting is used for gelatinization. It is characterized in that rice and 20% malt powder (accounting for the total amount of malt) are used for gelatinization at a water ratio of 1:5, the amount of auxiliary materials is 30% of the total amount of raw materials, and the feeding temperature is controlled at 50±1°C , keep warm for 15 minutes. While stirring, raise the temperature to 73±1°C at a rate of 1°C / min, and control the temperature for 10 minutes; within 15 minutes, raise the temperature to 85°C, then raise the temperature to 100°C, and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com