Ultra-thin varifocal optical system with low cost, simple process and very low temperature drift

A technology with simple process and temperature drift, which is applied in the field of zoom optical system, can solve the problems of performance degradation, increase of focusing time, wide-angle end focal length, etc., and achieve the effect of reducing production cost, reducing cost, and reducing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

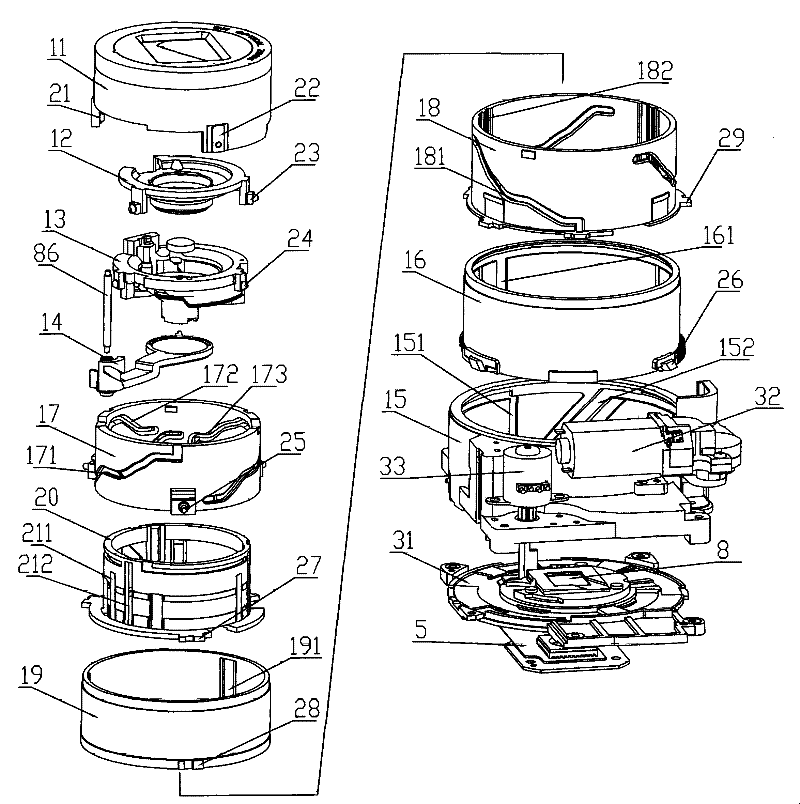

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

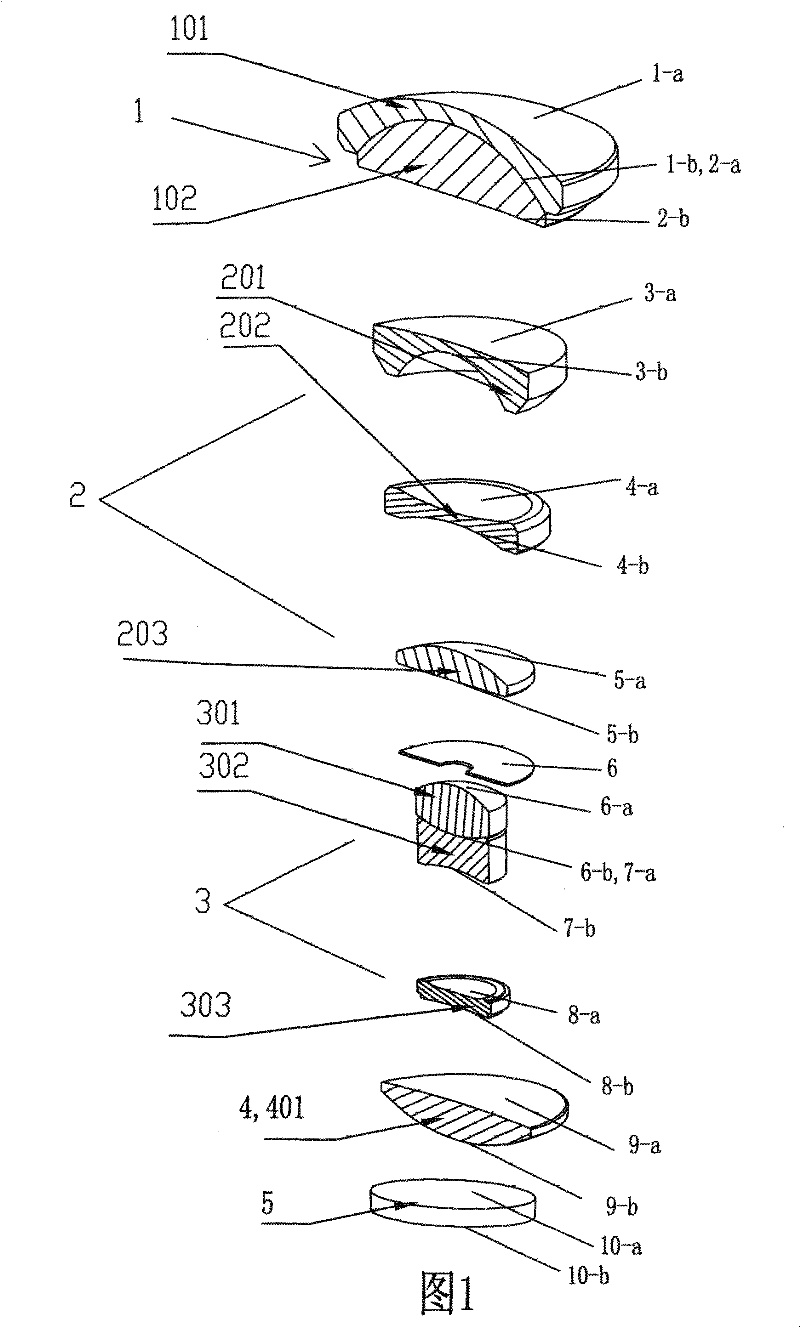

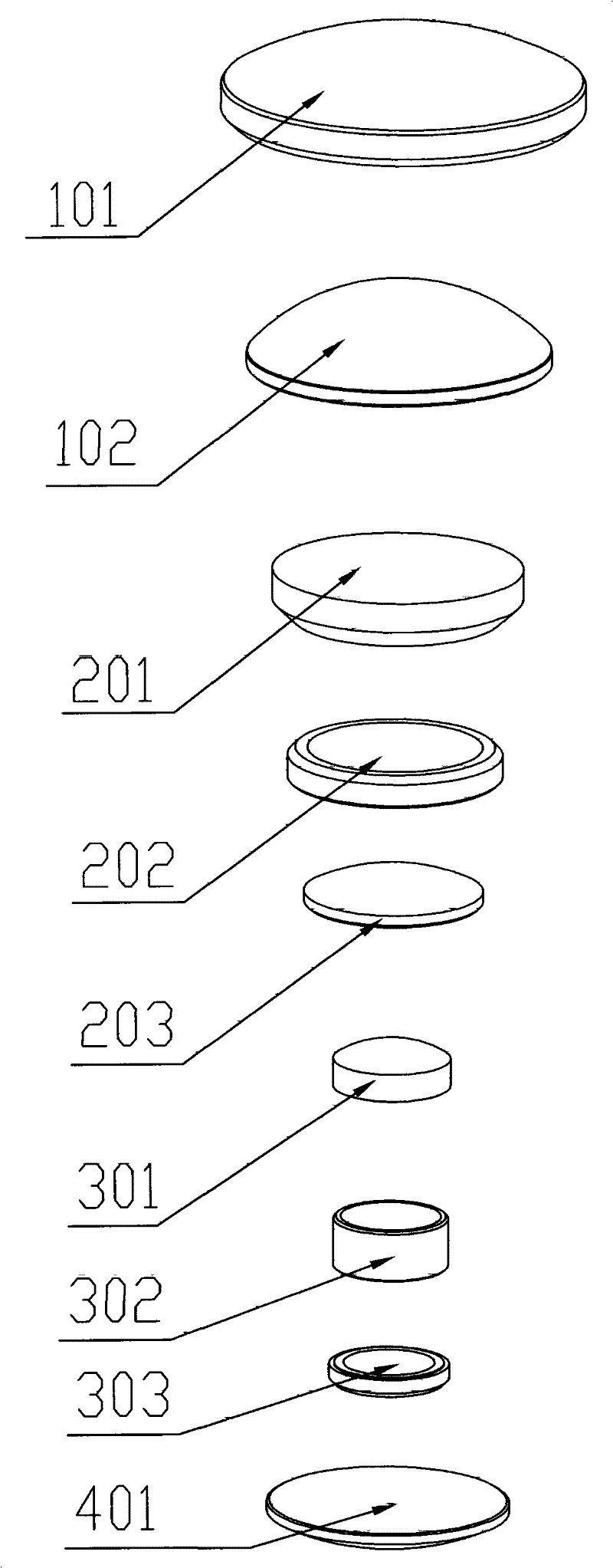

[0025] As shown in the figure, a low-cost, ultra-thin, simple process, and extremely low temperature drift zoom optical system includes a first lens group 1, a second lens group 2, a third lens group 3, and a fourth lens group 4 And photosensitive chip 5. A diaphragm 6 is provided between the second lens group 2 and the third lens group 3 . The positions of the first lens group 1, the second lens group 2, and the third lens group 3 change relative to the photosensitive chip during the zooming process, and the positions between the first lens group 1 and the second lens group 2 The relative position is variable, and the relative position between the second lens group 2 and the third lens group 3 is also variable.

[0026] The distance between the first lens group 1 and the second lens group 2 gradually increases during the change from the short focal length to the long focal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com