Method of separating target substance according to membrane separation and apparatus therefor

A technology of a target substance and a separation method, which is applied in the field of separation and device of target substances separated by membranes, can solve the problems of undisclosed methods of controlling selectivity, that is, the permeation tendency of target substances, and achieves a waste-free separation process, which is difficult to Thermal decomposition, effect of simple separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

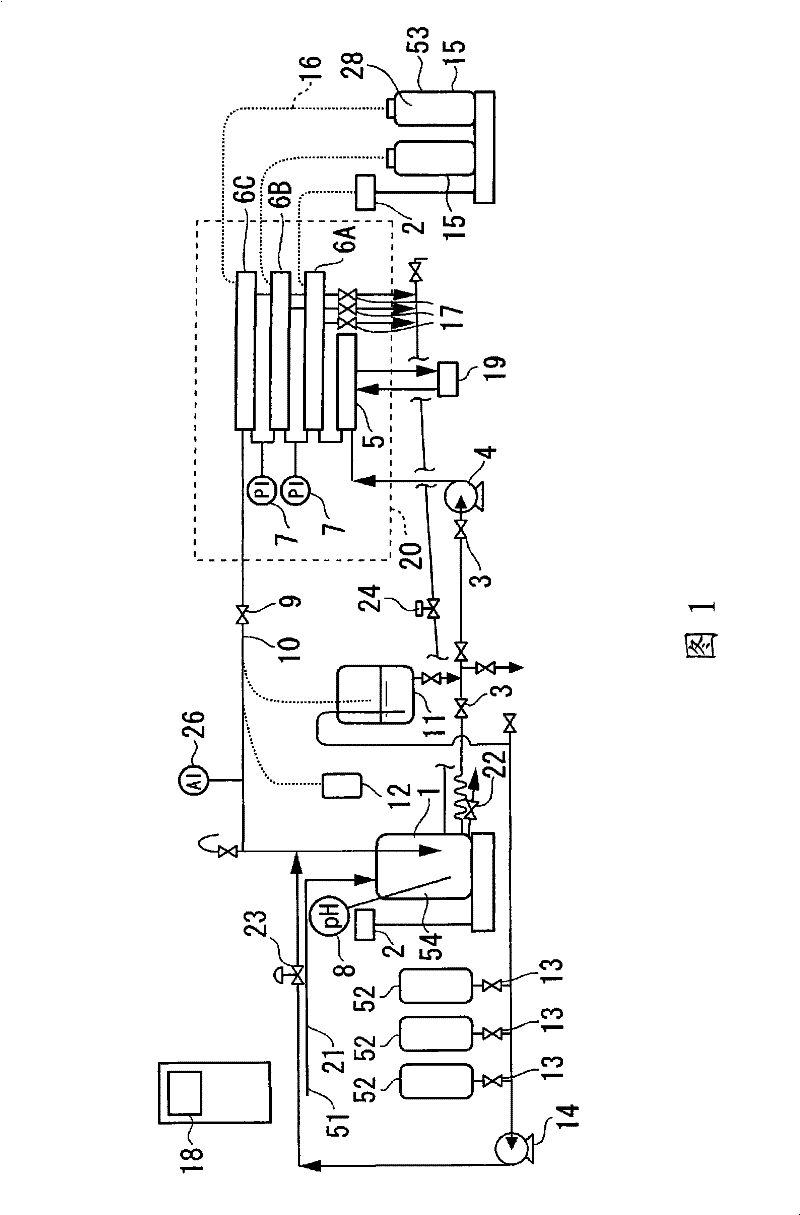

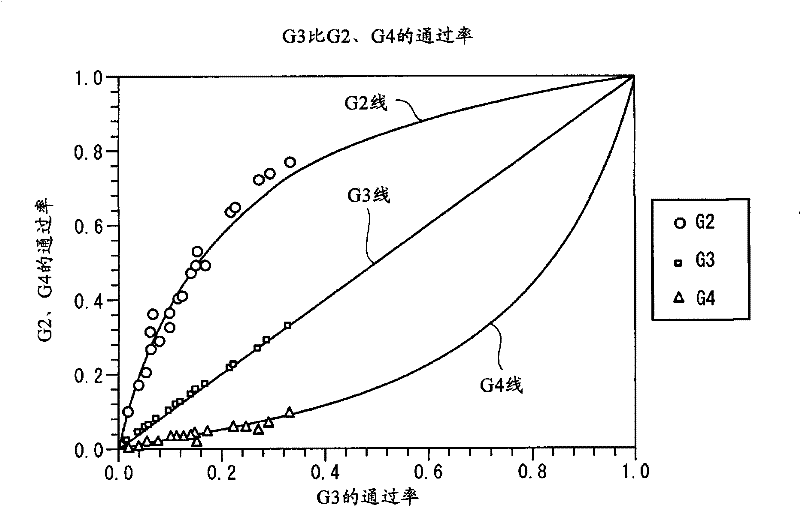

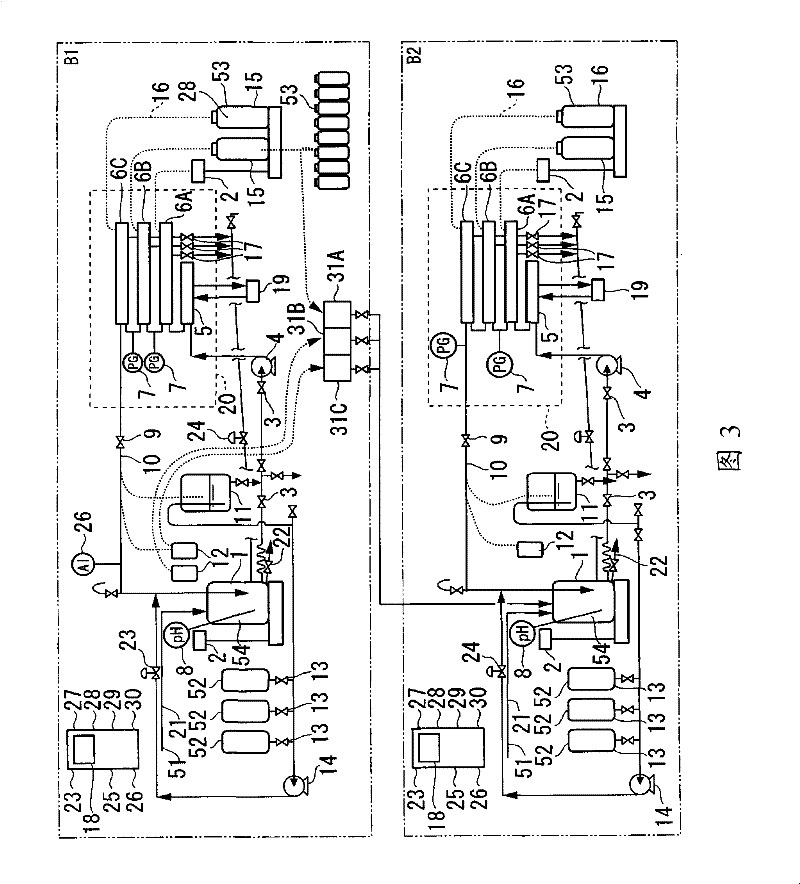

Embodiment 1

[0302] In this example, an example will be described in which a polyglycerol mixture containing a polyglycerol mixture containing glycerin, diglycerol, triglycerol, and tetraglycerin or higher, which is generally available as a decaglycerol mixture, is used as the stock solution and passed through a membrane Carry out purification, and record the sugar content of the permeate from the membrane separation device using nano-membrane in sequence. When the sugar content just reaches the specified value, reduce the operating pressure and reduce the flow rate of the permeate. For raw materials, glycerin and diglycerol are reduced to the original less than one tenth.

[0303]

[0304] Raw material composition Moisture 28.7wt%

[0305] Total Polyglycerol Concentration Equilibrium

[0306] Average degree of polymerization 10 polymers

[0307]

[0308] Use a concentrator to remove moisture to obtain a concentrated sample. Prepare in advance the internal standard solution obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com