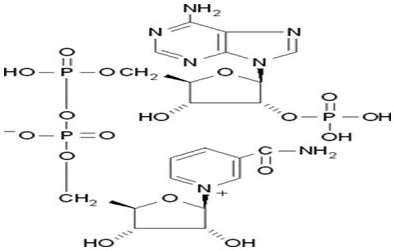

A kind of production method of oxidized nicotinamide adenine dinucleotide phosphate

A nicotinamide adenine and dinucleotide technology, applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low content, low product yield, complicated procedures, etc. The process is simple, the separation purity is high, and the cost of product use is minimized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Propagate with Bacillus megaterium or Bacillus subtilis, insert 5% of the inoculum into 30L of TB medium sterilized at 121°C for 20 minutes, use ammonia water to control pH7.0 throughout the process; initial speed 300 rpm Minutes, 600 rpm in the middle and late stages; initial flow rate 1:0.6, 1:1.2 in the middle and late stages; tank pressure 0.05MPa; after the dissolved oxygen rebounds, start to add 80% glycerin solution at a rate of 165ml / h; when OD600 ≥ 60 , the temperature was lowered from 37°C to 30°C, and the culture period was 42h. The OD600 of the tank is 98, and the volume of the tank is 34.2L.

[0033] (2) The NADP+ content of the fermentation broth was detected by HPLC to be 256mg / L.

[0034] (3) The fermentation broth was centrifuged at 8000 rpm to collect 6.82kg of bacterial cells.

[0035] (4) The bacteria were resuspended in 24L of deionized water, and homogeneously crushed twice under 60MPa pressure.

[0036] (5) Add 6.4g of chitosan to the crush...

Embodiment 2

[0039] (1) Product I in Example 1 was concentrated to 1.46L with a 300-600Da nanofiltration membrane.

[0040](2) Add 50g of strong acid cationic resin to the concentrated solution, the resin is Na+ type, adjust the pH to 2.8-3.0 with hydrochloric acid, stir for 0.5-4h, and adjust the pH at any time to keep it within the range of 2.8-3.0.

[0041] (3) Filtrate, collect 1.42L of filtrate, lower the pH to 1.5.0-2.0 with hydrochloric acid, put on a weakly acidic cationic resin column Φ35*350, the resin loading capacity is 150ml, the resin is pre-transformed into H+ type, and the sample loading flow rate is 2BV / h; After loading the column, rinse with 2BV deionized water.

[0042] (4) Desorb with 0.2M sodium hydroxide solution, and intercept 345ml of the intermediate desorption solution according to the detection index.

[0043] (5) The desorption liquid is adjusted to PH6.5 with hydrochloric acid, and the above-mentioned desorption liquid is desalted and concentrated with a nanof...

Embodiment 3

[0045] (1) Add 300ml of acetone dropwise to the product II in step (5) of Example 2 for 0.5h.

[0046] (2) After the dropwise addition, crystallize at -5--5°C for 6 hours.

[0047] (3) Vacuum filter with a Buchner funnel, top wash with 50ml of acetone, and collect the solid.

[0048] (4) The solid was vacuum-dried at ≤50°C for 4 hours to obtain 6.86 g of solid, namely product III. The content of NADP+ sodium salt was detected by HPLC to be 99.4%. Yield 88.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com