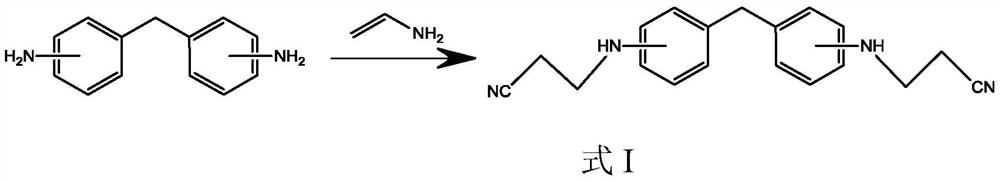

Preparation method of N, N'-dicyanoethyl-diaminodiphenyl methane

A technology of diaminodiphenylmethane and diaminodiphenyl, which is applied in the field of organic synthesis, can solve the problems of combustion and explosion, slow reactivity, and high reaction temperature, and achieve improved reactivity, high safety factor, and catalytic efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 2.0mol acrylonitrile, 0.15mol hydroquinone, 0.04mol Zn(AcO) to a 2L reactor 2 and 0.04mol HAc at 30°C under a nitrogen atmosphere for 60 min until the catalyst was completely dissolved.

[0032] (2) Within half an hour, the reaction temperature was raised to 80° C., and at this moment, a THF solution containing 1.0 mol of diaminodiphenylmethane was continuously added dropwise to the reaction mixture (the mass ratio of diaminodiphenylmethane to THF was 1:1), the dropping time does not exceed 1 hour. After the dropping is completed, react at a temperature of 80-85°C for 12 hours until the reaction of diaminodiphenylmethane is complete. Take 3 drops of the reaction solution and dilute it to 1ml with ethanol Chromatographic analysis showed that 20 ppm of acrylonitrile remained and the conversion rate of diaminodiphenylmethane was 98.9%.

[0033](3) Transfer the material to a 1L flask, heat the oil bath to 110°C, remove low-boiling acrylonitrile and tetrahydrofuran ...

Embodiment 2

[0036] (1) Add 2.0mol acrylonitrile, 0.15mol hydroquinone, 0.04mol Cu(AcO) into a 2L reactor 2 and 0.04mol HAc at 30°C under a nitrogen atmosphere for 60 min until the catalyst was completely dissolved.

[0037] (2) Within half an hour, the reaction temperature was raised to 80° C., and at this moment, a THF solution of 1.0 mol diaminodiphenylmethane was continuously added dropwise to the reaction mixture (the mass ratio of diaminodiphenylmethane to THF was 1 : 1), the dropping time is no more than 1 hour, after the dropping is finished, react at a temperature of 80-85° C. for 12 hours until the reaction of diaminodiphenylmethane is complete, take 3 drops of the reaction solution and dilute it to 1 ml with ethanol Chromatographic analysis showed that 45 ppm of acrylonitrile remained, and the conversion rate of diaminodiphenylmethane was 97.2%.

[0038] (3) Transfer the material to a 1L flask, heat the oil bath to 110°C, remove low-boiling acrylonitrile and tetrahydrofuran aft...

Embodiment 3

[0041] (1) Add 2.0mol acrylonitrile, 0.15mol hydroquinone, 0.04mol Al(AcO) into a 2L reactor 3 and 0.04mol HAc at 30°C under a nitrogen atmosphere for 60 min until the catalyst was completely dissolved.

[0042] (2) Within half an hour, the reaction temperature was raised to 80° C., and at this moment, a THF solution of 1.0 mol diaminodiphenylmethane was continuously added dropwise to the reaction mixture (the mass ratio of diaminodiphenylmethane to THF was 1 : 1), the dropping time is no more than 1 hour, after the dropping is finished, react at a temperature of 80-85° C. for 12 hours until the reaction of diaminodiphenylmethane is complete, take 3 drops of the reaction solution and dilute it to 1 ml with ethanol Chromatographic analysis showed that acrylonitrile remained at 32 ppm and the conversion rate of diaminodiphenylmethane was 98.0%.

[0043] (3) Transfer the material to a 1L flask, heat the oil bath to 110°C, remove low-boiling acrylonitrile and tetrahydrofuran afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com