Process and equipment for precise spray forming and layer-by-layer rolling repair and manufacturing

A spray forming and precision technology, applied in the field of precision spray forming-layer-by-layer rolling repair and manufacturing process and its equipment, can solve the problems of damaged wheel shape and dimensional accuracy, poor bonding, low metal spraying efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

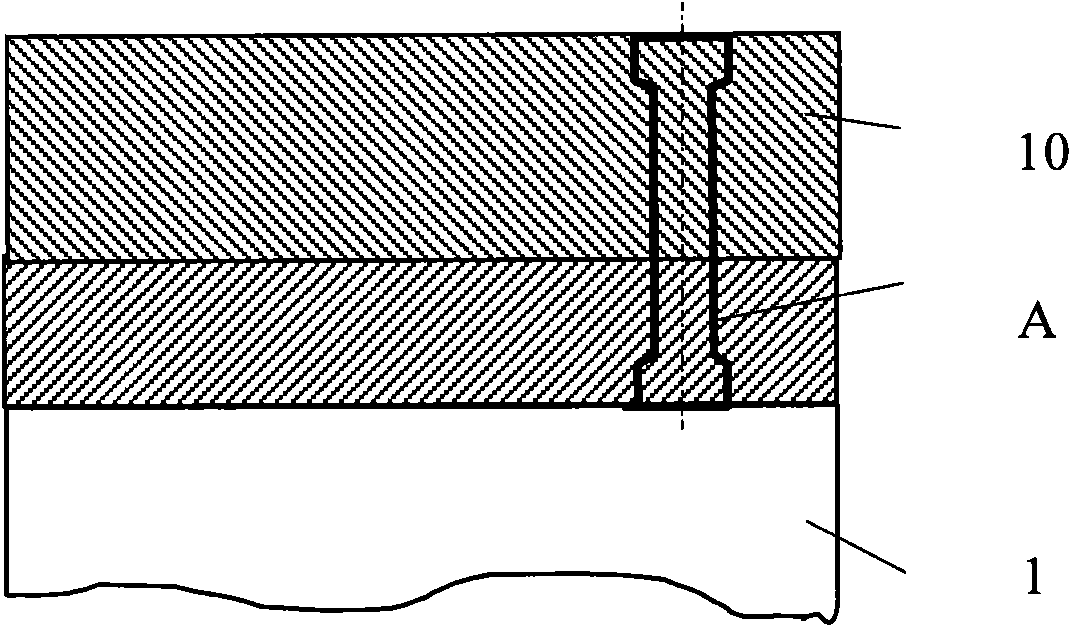

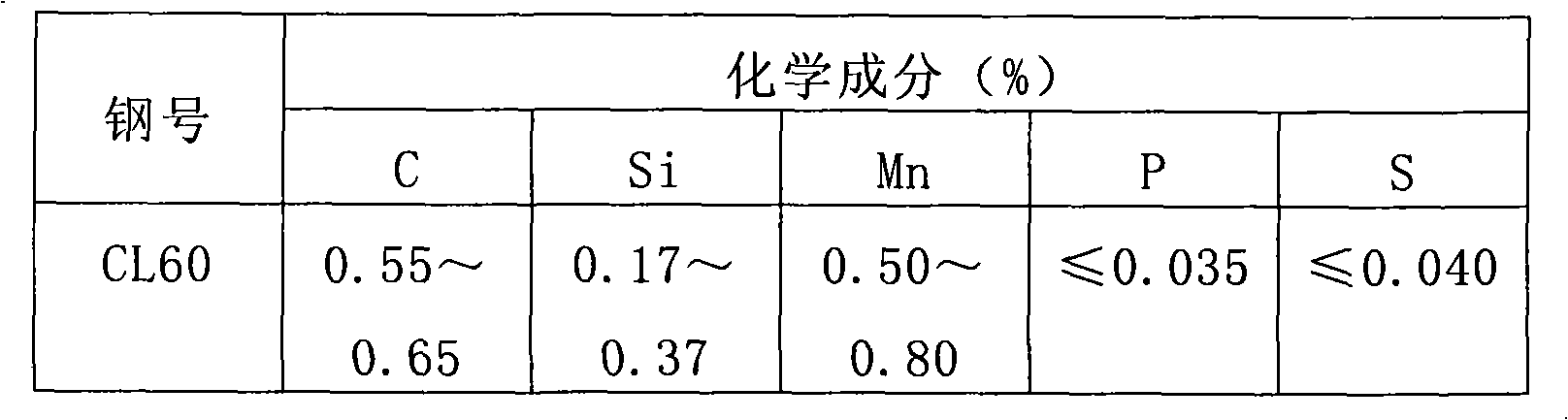

[0107] For example figure 2 The 138 mm wide rim 1 shown was spray coated, rolled and a sample of the metallic coating 10 was produced. Finally, two samples were obtained: sample 1-4 and sample 2-4. The rim and cladding metals are standard railway wheel steels whose composition is shown in Table 1. In addition, the same rim is only sprayed and coated without rolling, and another sample is made: comparative sample 1-1, to compare the superiority of the present invention.

[0108] The preparation methods of sample 1-4 and sample 2-4 are as follows:

[0109] The surface of the rim 1 is cleaned and processed; its surface is heated by induction under the protection of an inert gas (nitrogen), and the surface heating temperature is controlled at 1200° C.; the molten metal is atomized by a high-pressure inert gas (10 atmospheres) and sprayed and deposited on the The cladding metal is obtained on the surface of the cladding workpiece, and at the same time, the cladding metal is rol...

Embodiment 2

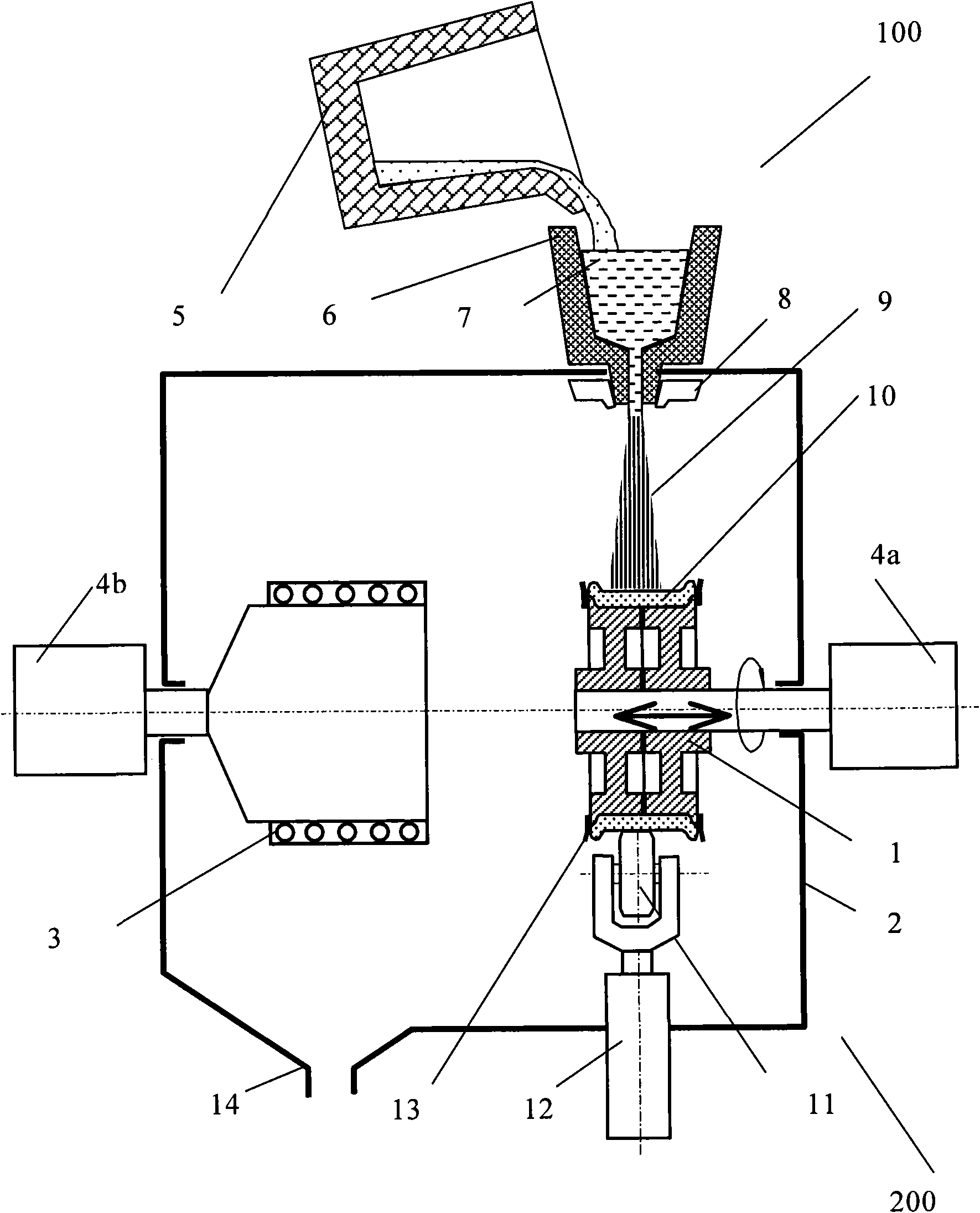

[0117] figure 1 It is a schematic diagram of the process and equipment of the present invention. Take the repair of a pair of railway wheels 1 as an example, they were scrapped due to outer circle wear.

[0118] A spray chamber 2 is provided in the equipment, and a spray unit 100 is arranged on the top of the spray chamber 2. The spray unit 100 includes: a liquid metal smelting preparation or supply device 5; the metal liquid smelting preparation or supply device 5 provides a molten metal 7; An inert gas atomization injection device 8 is arranged downstream of the liquid smelting preparation or supply device 5; the inert gas atomization injection device 8 makes the molten metal 7 atomized and sprayed onto the workpiece (that is, the wheel) 1 to be coated A metal coating 10 is formed.

[0119] The lower part of the spray chamber 2 is provided with a layer-by-layer rolling repair and manufacturing unit 200, including: a heating device 3 located around the workpiece 1 to be coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com