Vertical-blanking-mode material distributing machine of ceramic presser and distributing method thereof

A distributing machine, vertical technology, applied in ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of rising costs, increasing the space occupied by the distributing machine, etc., and achieve the effect of small changes in texture patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] The specific implementation manner of the first embodiment:

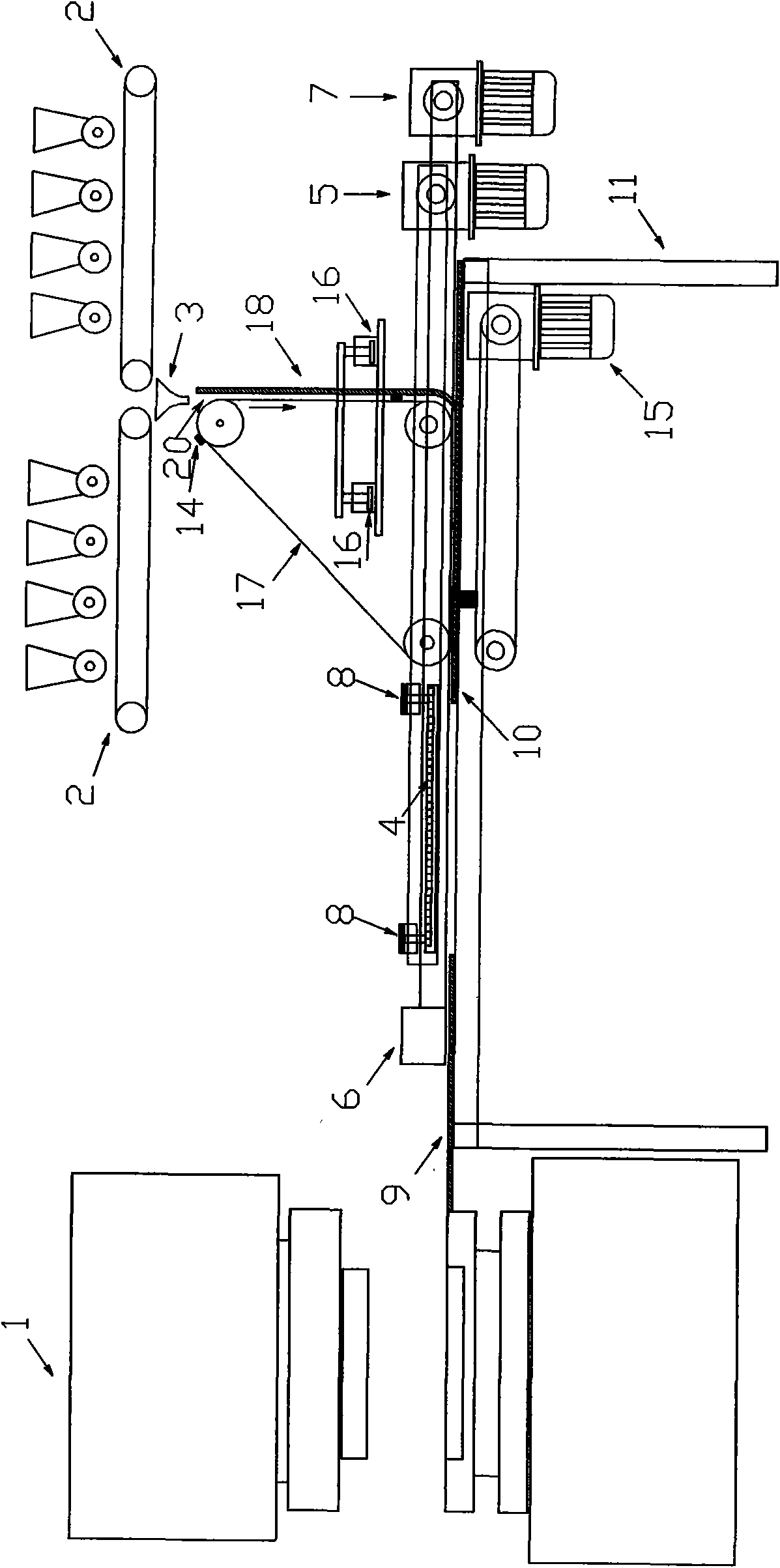

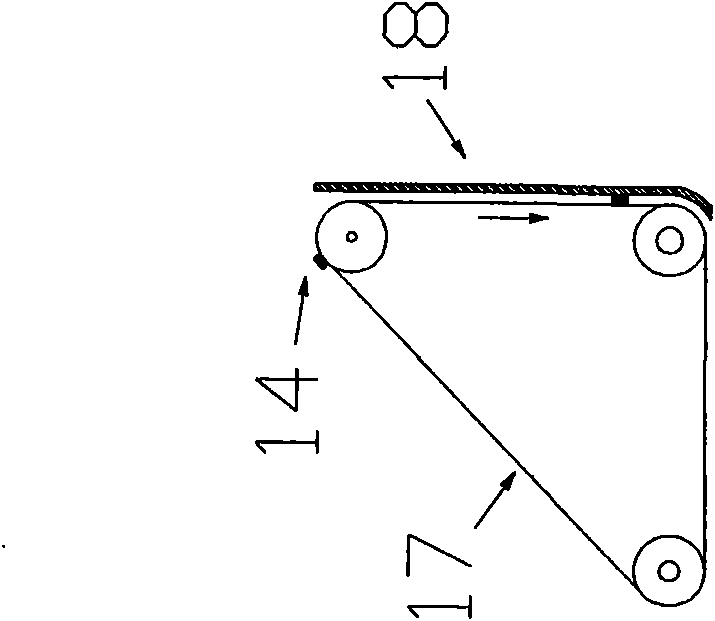

[0043] exist figure 1 Among them, the feeding device 2 drops the powder vertically from the hopper 3 into the longitudinal material receiving cavity 20 formed by a 90-degree triangular flat belt 17 and a rear cover 18. The bottom end of the rear cover 18 forms a concentric Round corner, the arc corner is 90 degrees. Angle 90 degree triangular plane belt 17 rotates downwards, drives the powder guide bar 14 that is provided with on it to support powder material, descends by the speed of corner 90 degree triangular plane belt 17, the speed that this powder guide bar moves and fills into vertical material receiving cavity ( 20) The amount of powder in the interior is synchronized so that the drop of the powder vertically falling into the material receiving cavity remains stable. When the powder falls to the set height, the feeding device 2 stops feeding, and the triangular flat belt 17 with a corner angle of 90...

no. 2 example

[0044] The specific implementation manner of the second embodiment:

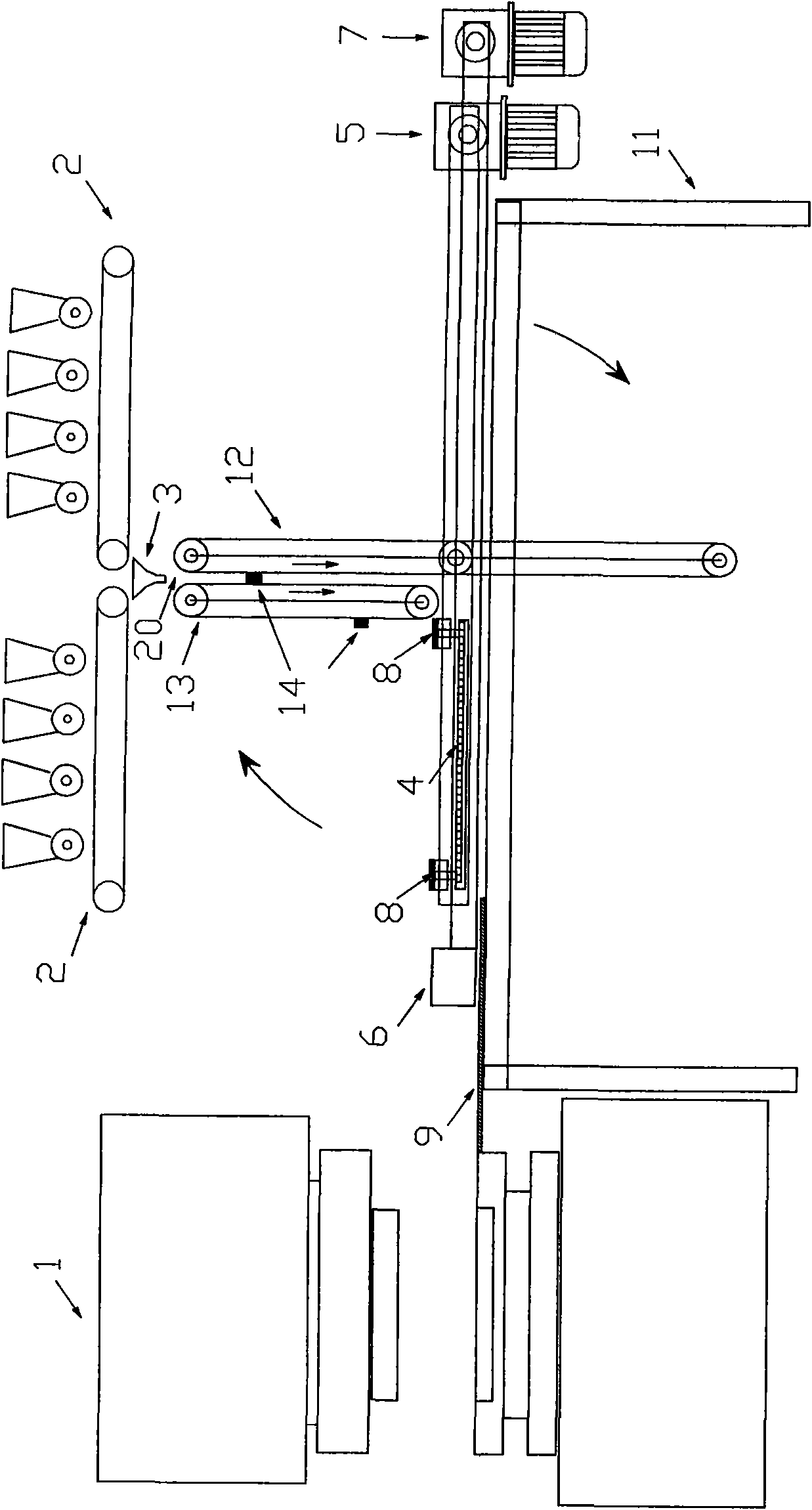

[0045] exist figure 2 In the feeding device 2, the powder is vertically dropped from the lower hopper 3 into the vertical material receiving cavity (20) formed between the plane belt 12 turned over 90 degrees and the additional plane belt 13. Additional plane belt (13) and the two planes of overturning 90 degree plane belt (12) have about 5 degree of inclinations. Overturn 90 degree plane belt 12 and rotate downwards, meanwhile, additional plane belt 13 also rotates downwards with synchronous speed, the powder guide bar 14 that is arranged on the additional plane belt 13 supports powder, descends by the speed of additional plane belt 13, Synchronize the moving speed of the powder guide bar (14) with the amount of powder filled into the longitudinal material receiving cavity (20), so that the drop of the powder falling vertically into the material receiving cavity remains stable, and when the powder falls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com