Halogen-free expandable fire retardant fiber glass reinforced polypropylene material and preparation method thereof

A polypropylene material and expansion type technology, applied in the field of composite materials, can solve the problems of insufficient combustion order and flame retardant requirements, etc., and achieve the effects of excellent mechanical properties, widened application range, and strong impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~2

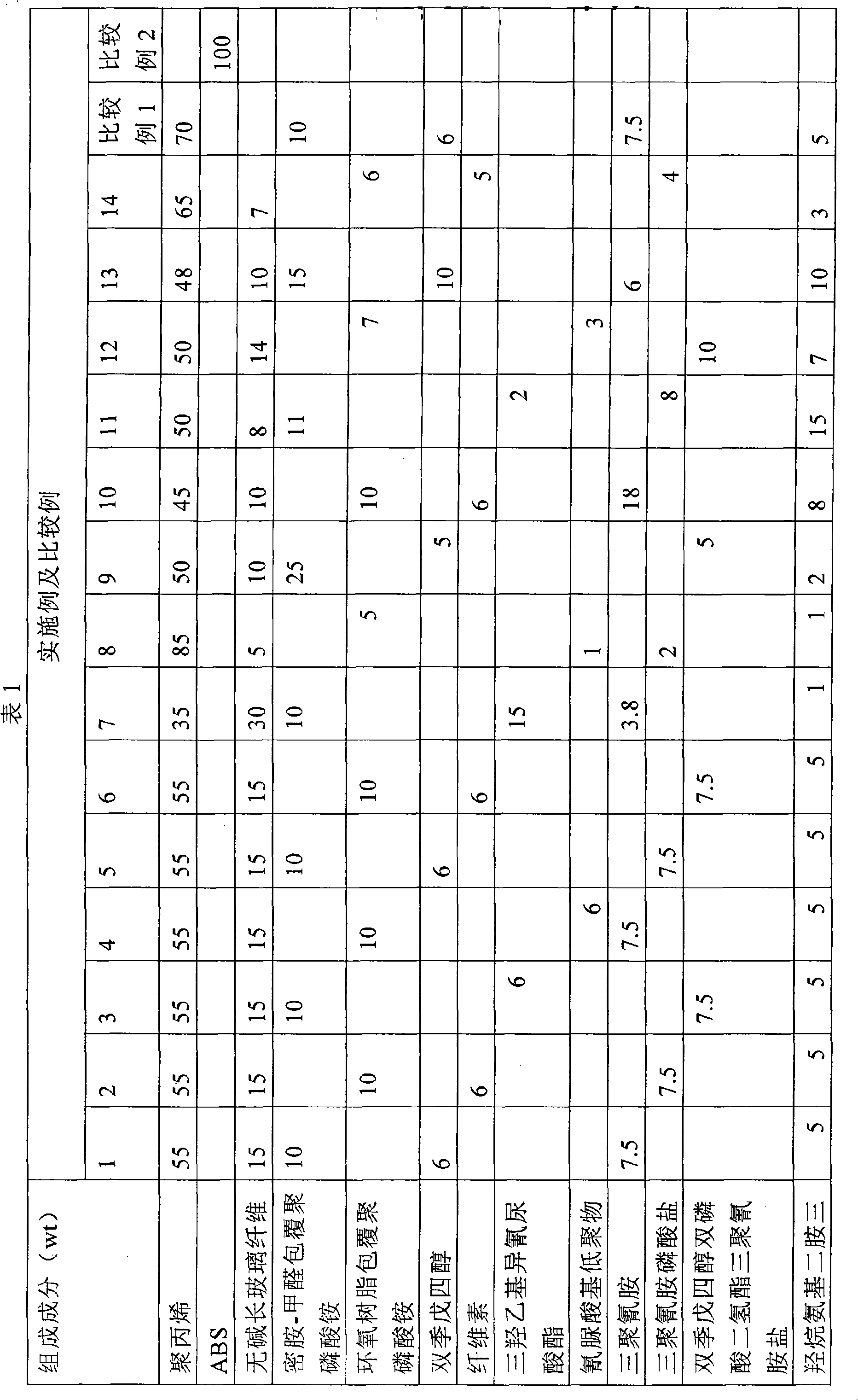

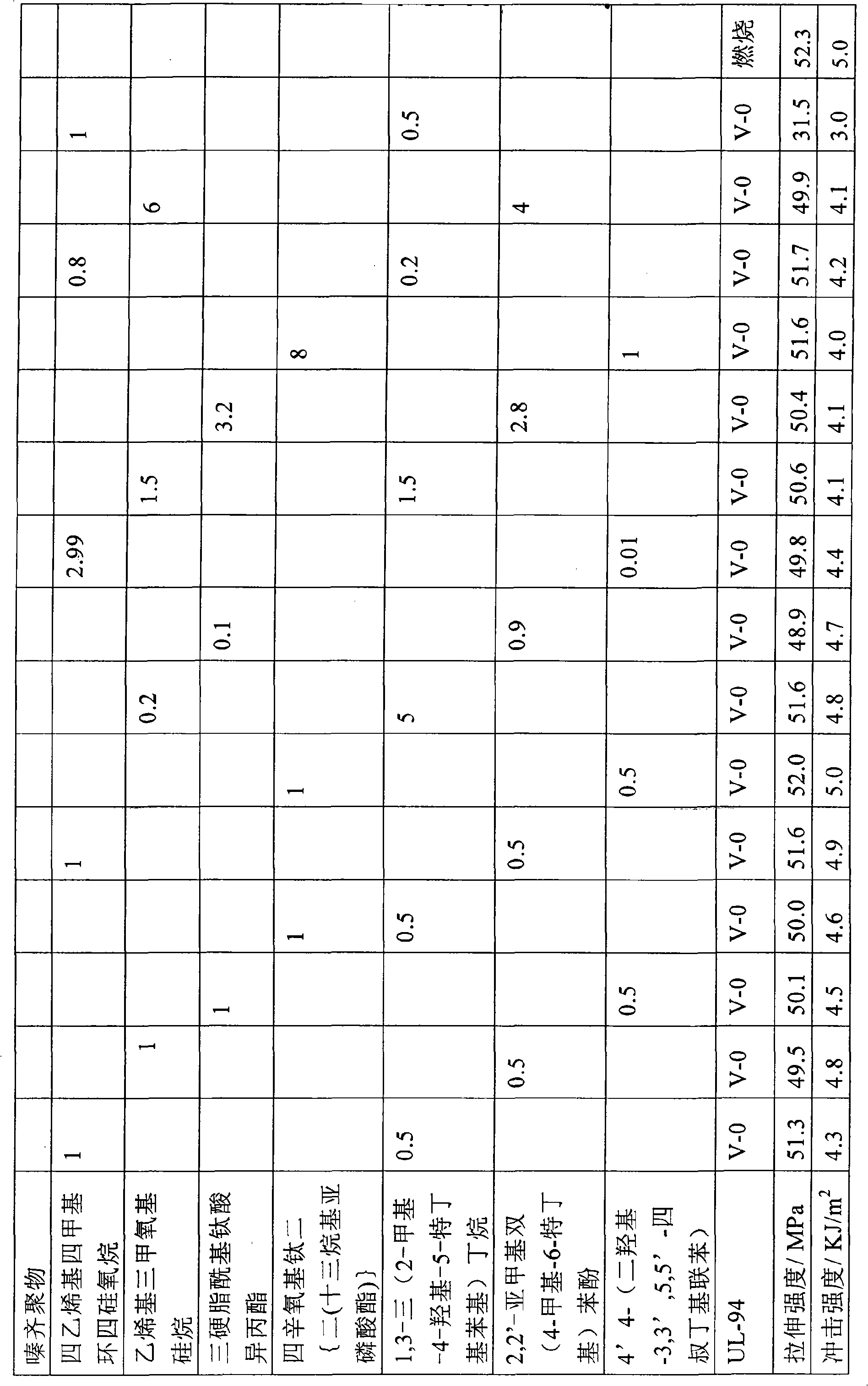

[0021] See Table 1, according to the data listed in Table 1, the coated ammonium polyphosphate, polyols, melamine and its derivatives, and macromolecular triazine derivatives are premixed in a high-speed mixer, and then pulverized by a jet mill to obtain Halogen-free intumescent flame retardant, and then polypropylene, the above-mentioned halogen-free flame retardant, glass fiber, coupling agent, and antioxidant are extruded and mixed through an extruder, and the mixing temperature is 165-220°C. When kneading and extruding, glass fiber, coupling agent and antioxidant are added from the side feed port of the extruder, and the rest of the material is fed into pellets from the feeder of the extruder, and then injected into samples, tested for performance, and obtained The results are also shown in Table 1. Compared with Comparative Example 1 and Comparative Example 2, it can be seen that the present invention can reach UL-94 V-0 level in terms of flame retardancy, and the mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap